6060 Enclosed Large Cabinet 600×600 Fiber Laser Cutting Machine 1000/1500/2000/3000/6000W Metal Steel Gold Cutter Customized

Product Detail

Product Tags

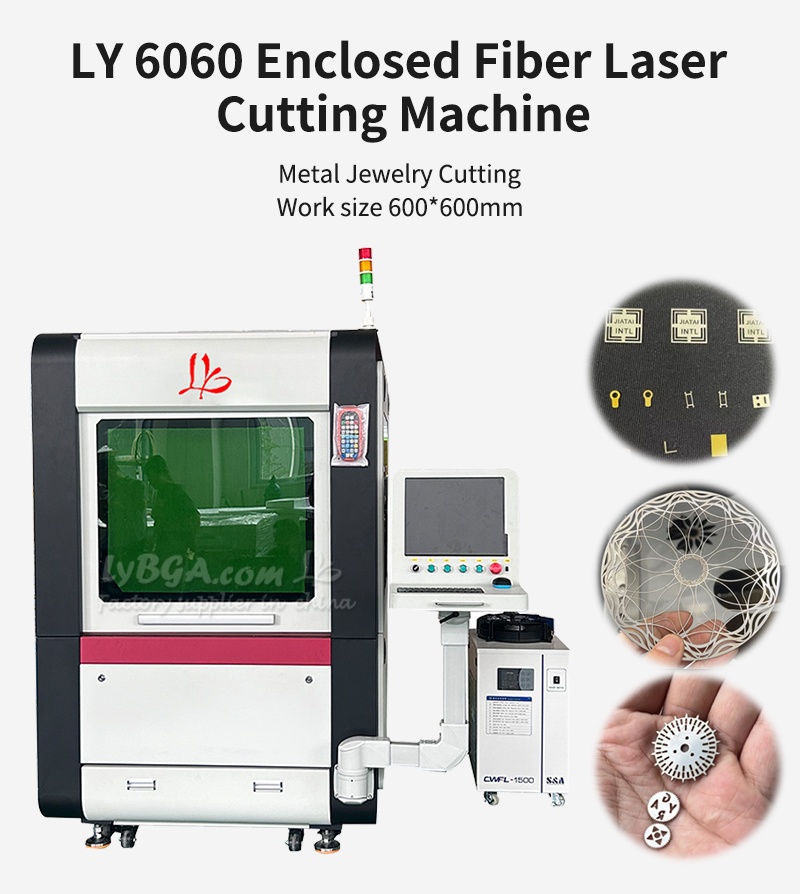

LY 6060 Enclosed Fiber Laser Cutting Machine Customized Stainless steel brass metal fast cutting 600*600mm processing small parts Water-cooled Auto/Manual Focus

LY 6060 Enclosed CNC Fiber Laser Cutting Machine Customized Metal Jewelry Cutting Large and Small Parts Cutting Crafts Cutting Chiller

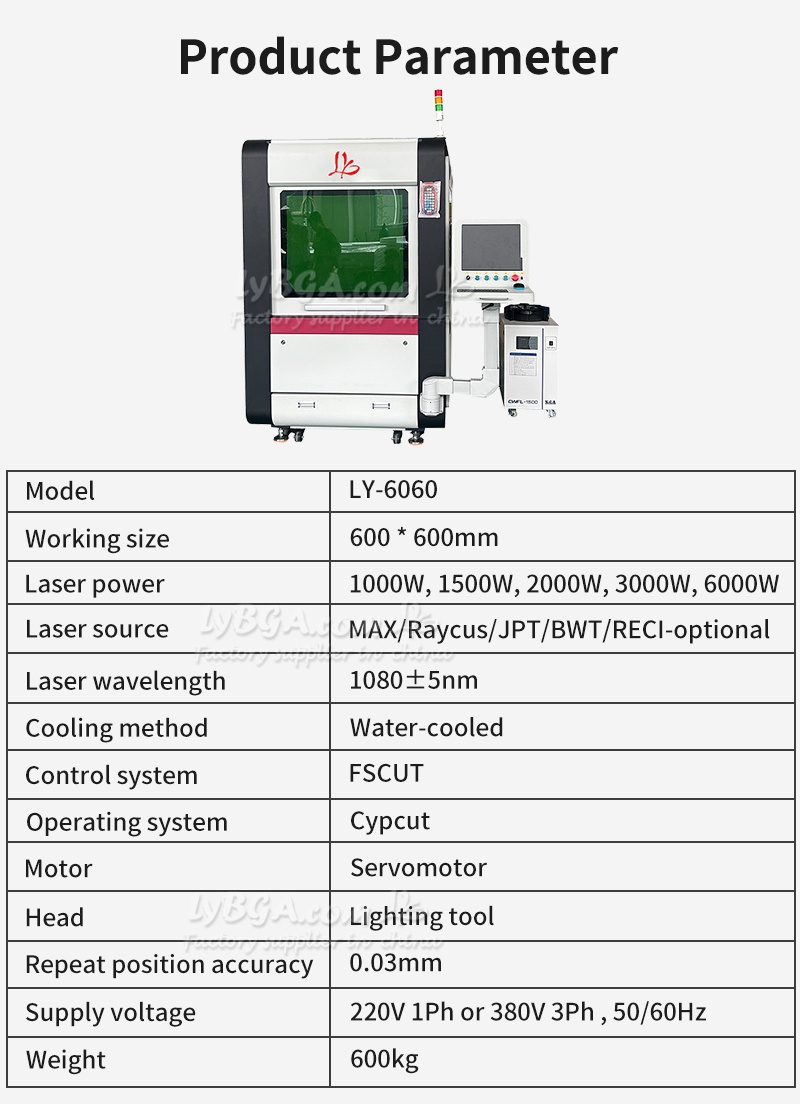

Product Parameter

|

Model |

LY-6060 |

|

Working size |

600 * 600mm |

|

Laser power |

1000W, 1500W, 2000W, 3000W, 6000W |

|

Laser source |

MAX/Raycus/JPT/BWT/RECI-optional |

|

Laser wavelength |

1080±5nm |

|

Cooling method |

Water-cooled |

|

Control system |

FSCUT |

|

Operating system |

Cypcut |

|

Motor |

Servo motor |

|

Head |

Light tool |

|

Repeat position accuracy |

0.03mm |

|

Supply voltage |

220V 1Ph or 380V 3Ph , 50/60Hz |

|

Weight |

600kg |

Closed CNC Fiber Laser Cutting Machine

The enclosed fiber laser cutting machine, available in 1500W, 2000W and 3000W power options, is designed for precision cutting and is particularly suitable for small, precision workpieces such as watch parts. Its 600x600mm working area ensures that even the most complex cutting tasks can be completed with ease. With advanced fiber laser technology, it can not only efficiently process small parts, but also cope with the cutting needs of larger workpieces, ensuring extremely high cutting accuracy and stability, making it an ideal device for industrial production in pursuit of high quality and efficiency.

Advantages and features:

High Precision Cutting: Ensure perfect processing of precision parts, suitable for watch parts and other small workpieces.

Efficient production: High stability, reducing downtime and increasing productivity.

Low Maintenance: Fiber laser technology does not require frequent replacement of parts, reducing maintenance costs.

Multiple power options: 1500W, 2000W, 3000W to meet different needs, adapt to a variety of materials and thickness.

Environmental protection and energy saving: energy saving and high efficiency, reduce energy consumption and environmental impact

Main Configurations

Fiber Laser Source

MAX is a high quality laser for fiber cutting machine applications. Different brands and power lasers are available, the higher the power, the thicker and the cut.

Laser cutting head

Anti-collision design, highly adjustable high sensitivity

Servo Motorcycle

High-quality servo motor, realizing closed-loop control of position, speed and torque; overcoming the problem of stepping motor not stepping, With high speed performance, generally rated speed up to 2000 ~ 3000 rpm. with high stability: low-speed smooth operation.

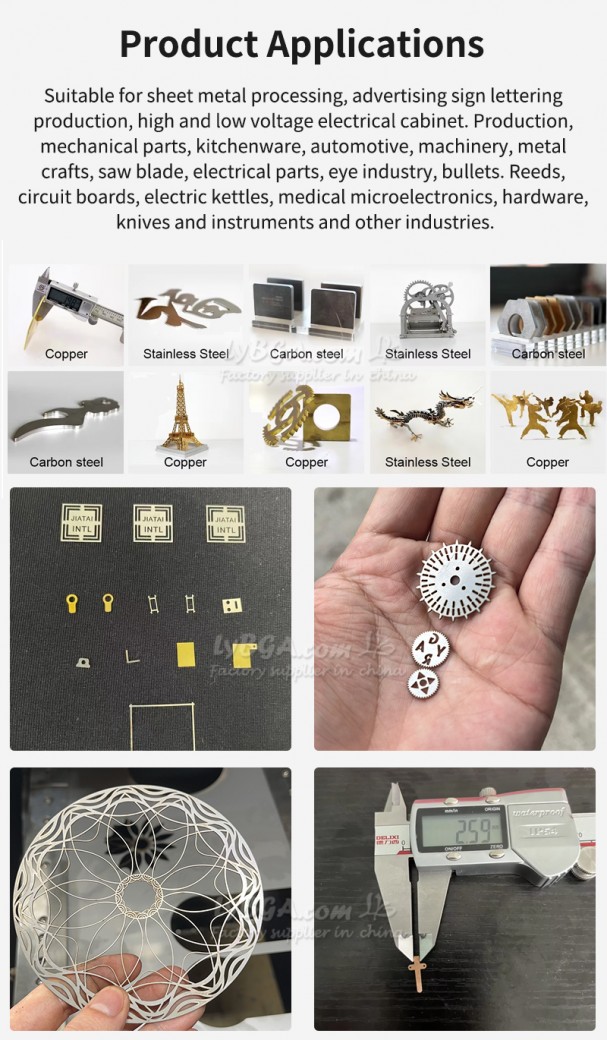

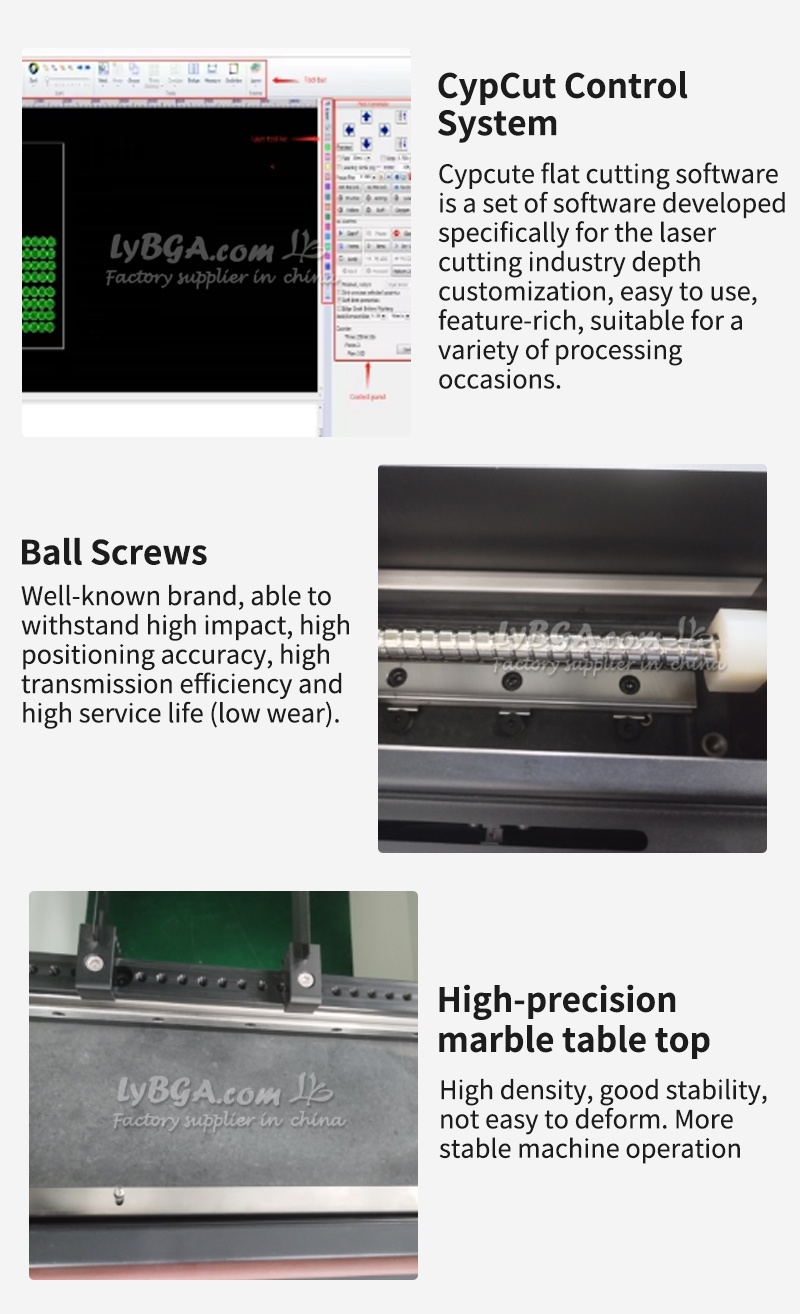

CypCut Control System

Cypcute flat cutting software is a set of software developed specifically for the laser cutting industry depth customization, easy to use, feature-rich, Suitable for a variety of processing occasions.

Ball Screws

Well-known brand, able to withstand high impact, high positioning accuracy, high transmission efficiency and high service life (low wear)

High-precision marble table top

High density, good stability, not easy to deform, more stable machine operation

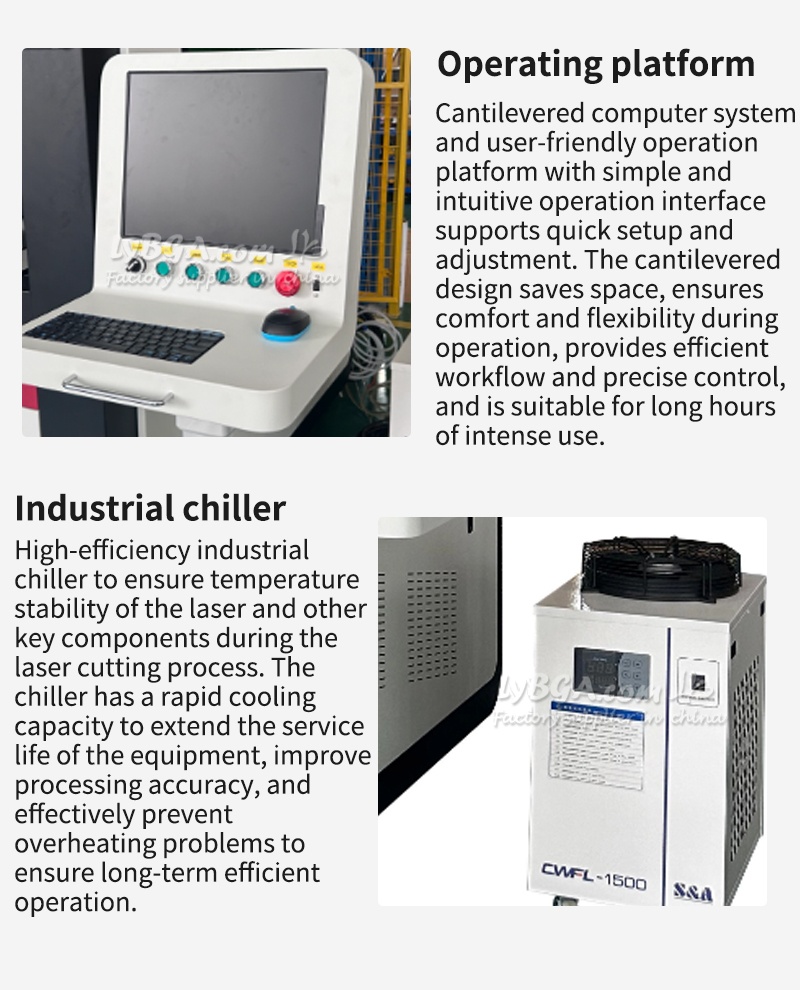

Operating platform

Cantilevered computer system and user-friendly operation platform with simple and intuitive operation interface supports quick setup and adjustment. The cantilevered design saves space, ensures comfort and flexibility during operation, provides efficient workflow and precise control, and is suitable for long hours of intense use.

Industrial chiller

High-efficiency industrial chiller to ensure temperature stability of the laser and other key components during the laser cutting process, The chiller has a rapid cooling capacity to extend the service life of the equipment, improve processing accuracy, and effectively prevent overheating problems to ensure long-term efficient operation.

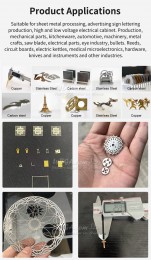

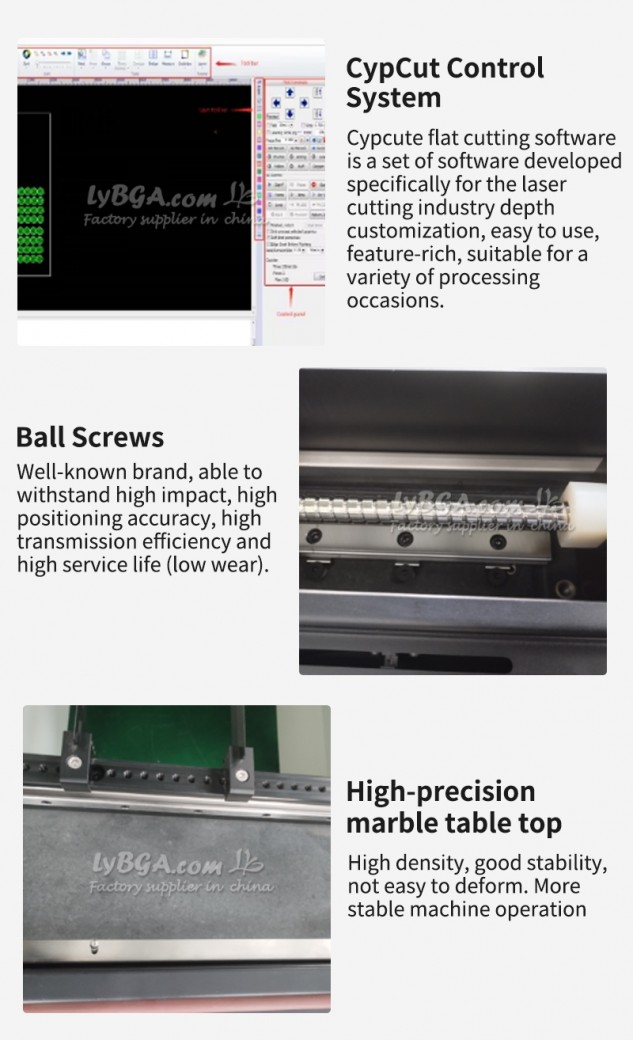

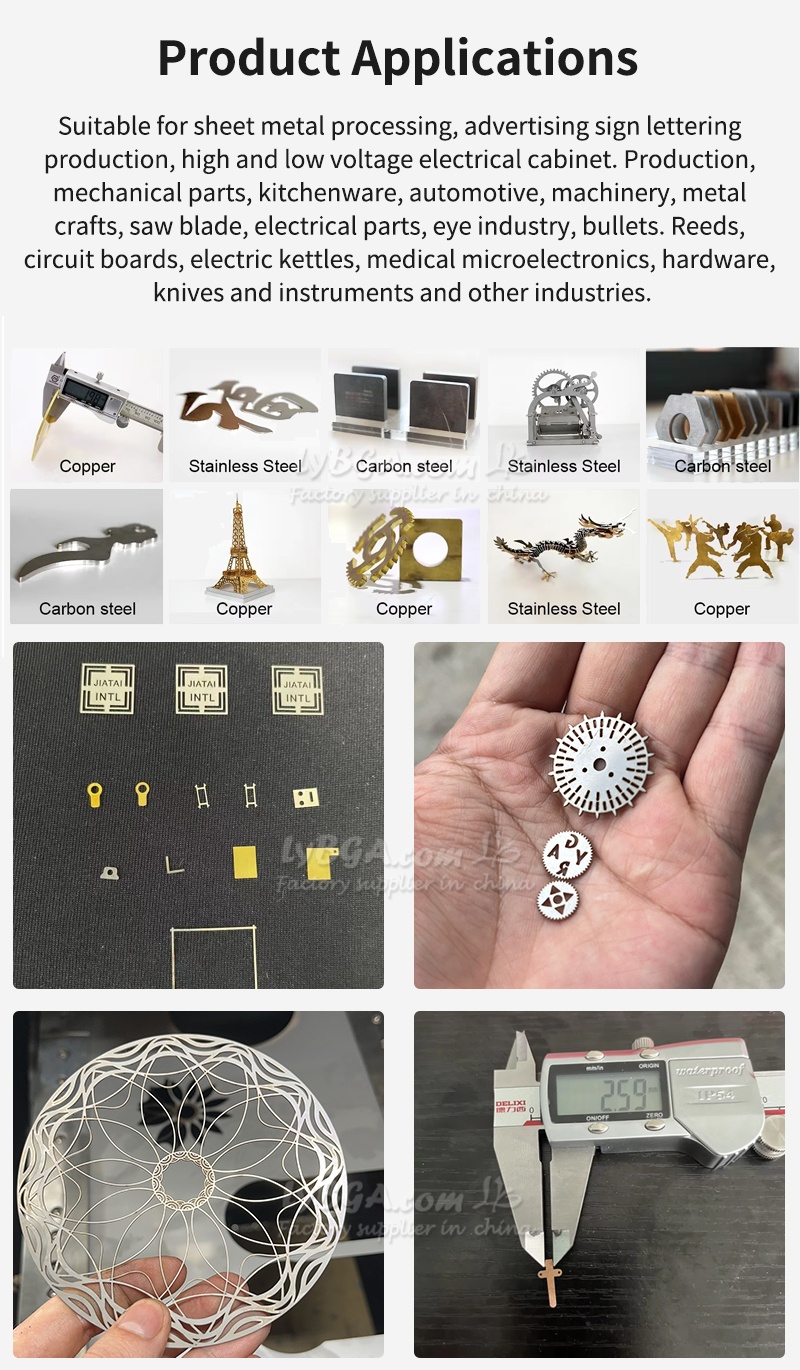

Product Application

Suitable for sheet metal processing, advertising sign lettering production, high and low voltage electrical cabinet, Production, mechanical parts, kitchenware, automotive, machinery, metal crafts, saw blade, electrical parts, eye industry, Bullets. Reeds, circuit boards, electric kettles, medical microelectronics, hardware, knives and instruments and other industries,

Optional cutting head (Auto/Manual Focus)

Auto focus laser head

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position. The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials.

Product Description

High Precision

Servo Motor and Precision Guide way

Smooth Marble Work Surface

Fully Enclosed Door Protection

Metal Cutting

Jewelry Cutting

Durable and Stable

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!