Auto Label Stripping And Applicator Machine For Label Peeling Customized Length 5 to 150mm Portable Sticker Separating

Product Detail

Product Tags

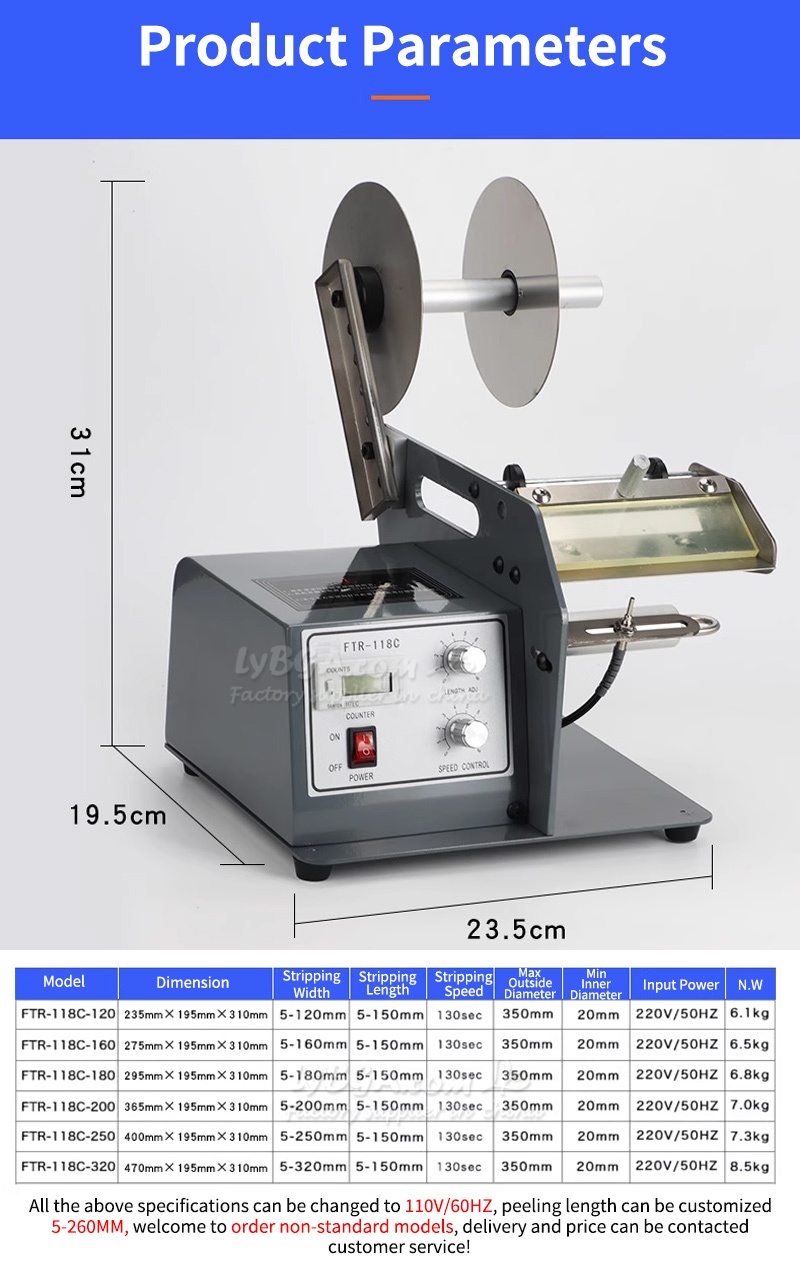

Equipment parameters

|

Model |

Dimension (L*W*H) |

Label Width |

Stripping Length |

Peeling Speed |

Max Outside Diameter |

Minimum Inner Diameter |

Input Power |

Weight |

|

118C-120 |

235mm*195mm*310mm |

5-120mm |

5-150mm |

130sec |

350mm |

20mm |

220V/50HZ |

6.1kg |

|

118C-160 |

275mm*195mm*310mm |

5-160mm |

5-150mm |

130sec |

350mm |

20mm |

220V/50HZ |

6.5kg |

|

118C-180 |

295mm*195mm*310mm |

5-180mm |

5-150mm |

130sec |

350mm |

20mm |

220V/50HZ |

6.8kg |

|

118C-200 |

365mm*195mm*310mm |

5-200mm |

5-150mm |

130sec |

350mm |

20mm |

220V/50HZ |

7.0kg |

|

118C-250 |

400mm*195mm*310mm |

5-250mm |

5-150mm |

130sec |

350mm |

20mm |

220V/50HZ |

7.3kg |

|

118C-320 |

470mm*195mm*310mm |

5-320mm |

5-150mm |

130sec |

350mm |

20mm |

220V/50HZ |

8.5kg |

Weight Information

|

Model |

Weight per unit |

Outer box size |

Weight and number of pieces per case |

Carton size |

|

118C-120 |

6kg |

34*28.5*26 |

12kg/2 units |

62*38.5*24 |

|

118C-160 |

6kg |

40.8*29.5*21.5 |

12kg/2 units |

62*43*24 |

|

118C-180 |

6kg |

40.8*29.5*21.5 |

12kg/2 units |

62*43*24 |

|

118C-200 |

6kg |

40.8*29.5*21.5 |

12kg/2 units |

62*43*24 |

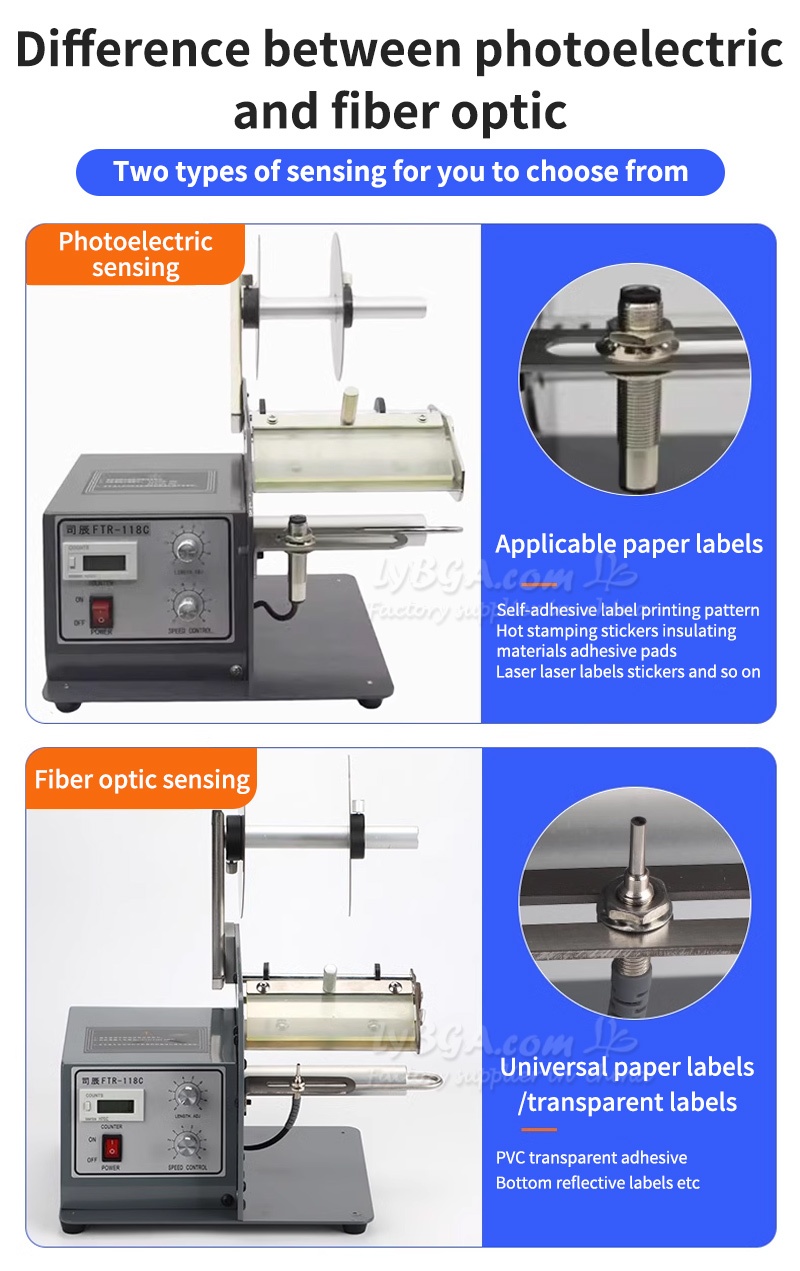

Functional difference:

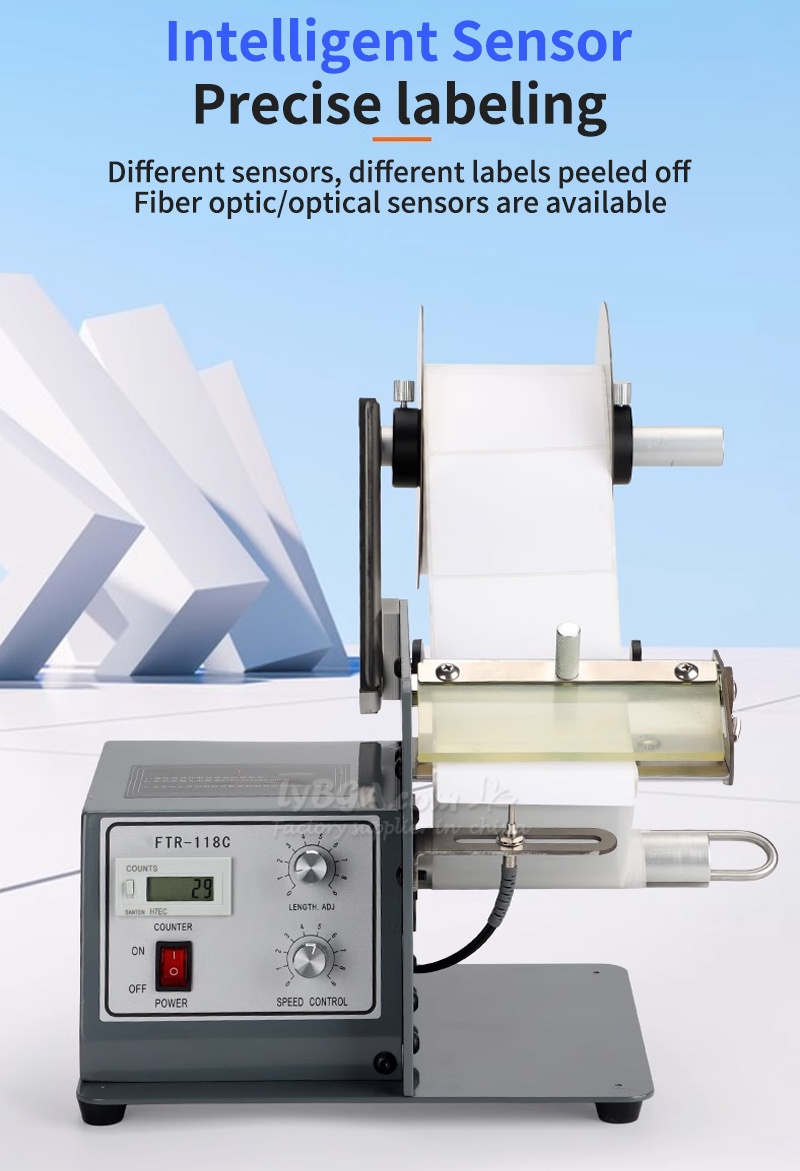

Photoelectric induction: suitable for label size, clean environment and detection of long distance scenes, such as conventional paper label peeling.

Fiber optic sensing: more suitable for high-precision detection needs (such as ultra-thin labels, transparent film) or harsh working conditions (high temperature production line, oil environment), such as medical labels, electronic components label peeling

Operation and use

1, the label as shown in the picture, mounted on the waste shaft

2、U-shaped card will be labeled with the front section of the card into the “waste shaft”; 3、Adjust the “ring” so that the label will not sway from side to side.

3, adjust the “ring”, so that the label will not sway from side to side.

4, the motor speed and delay time to the minimum

5、Turn on the power switch.

6, according to the length of the label to adjust the motor speed and delay time

7, adjusted to the appropriate speed and time to work normally.

Basic use

Used for the automatic peeling of labels, the peeled label is taken, automatically peeled off the next label after it is removed, improving the efficiency of workers in removing labels. Multiple rows of labels can be peeled off at one time.

Scope of application: electronic manufacturing industry, chemical pharmaceutical industry, food processing industry, logistics and distribution industry, etc.

Applicable labels: self-adhesive labels, self-adhesive film, electronic monitoring code, bar code, etc.

Applicable products: all products requiring labeling or film

Applicable industries: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastic, printing, etc.

Examples of application: toy assembly line. Labeling on the line, food packaging box assembly line labeling, electronic products assembly line, etc

Detail page text

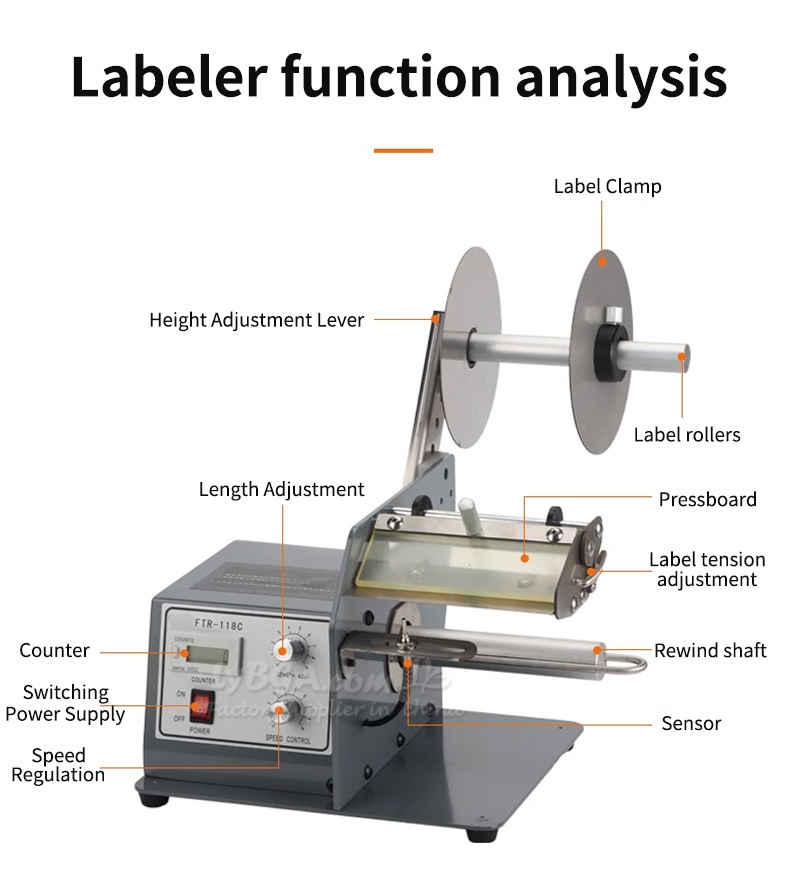

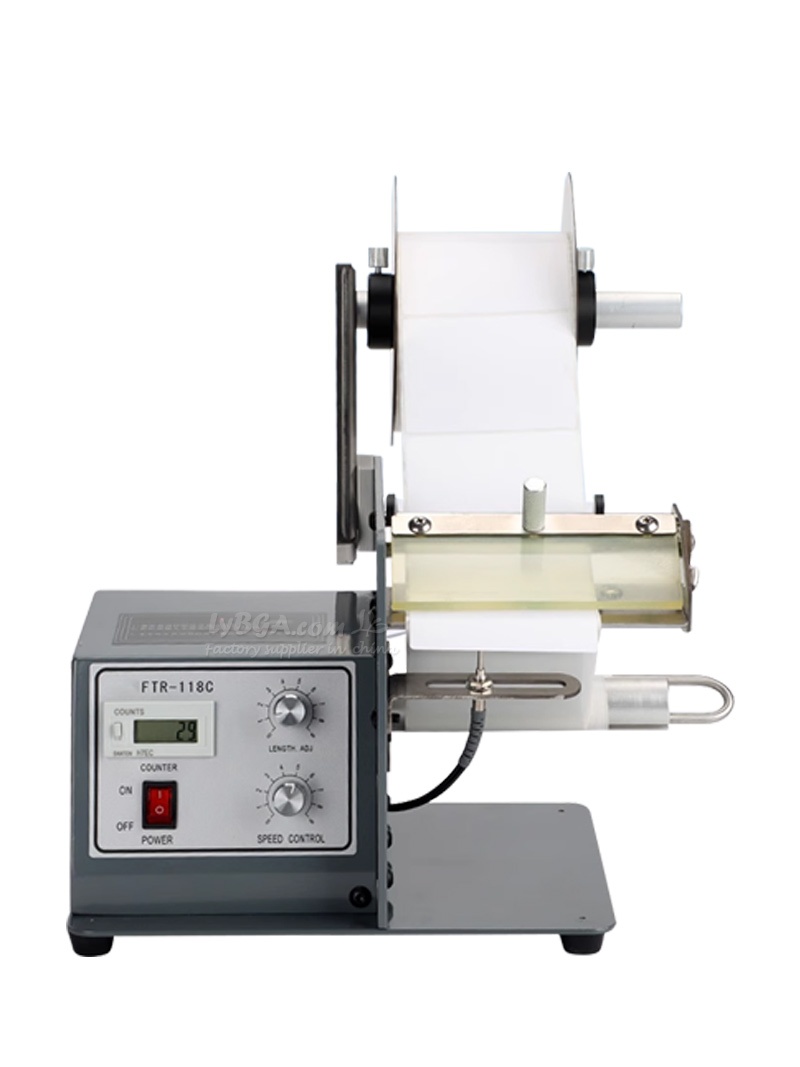

FTR-118C Label Peeling Machine

Automatic peeling transparent sealing sticker

Precise Sensing

Smooth label release

Transparent peeling

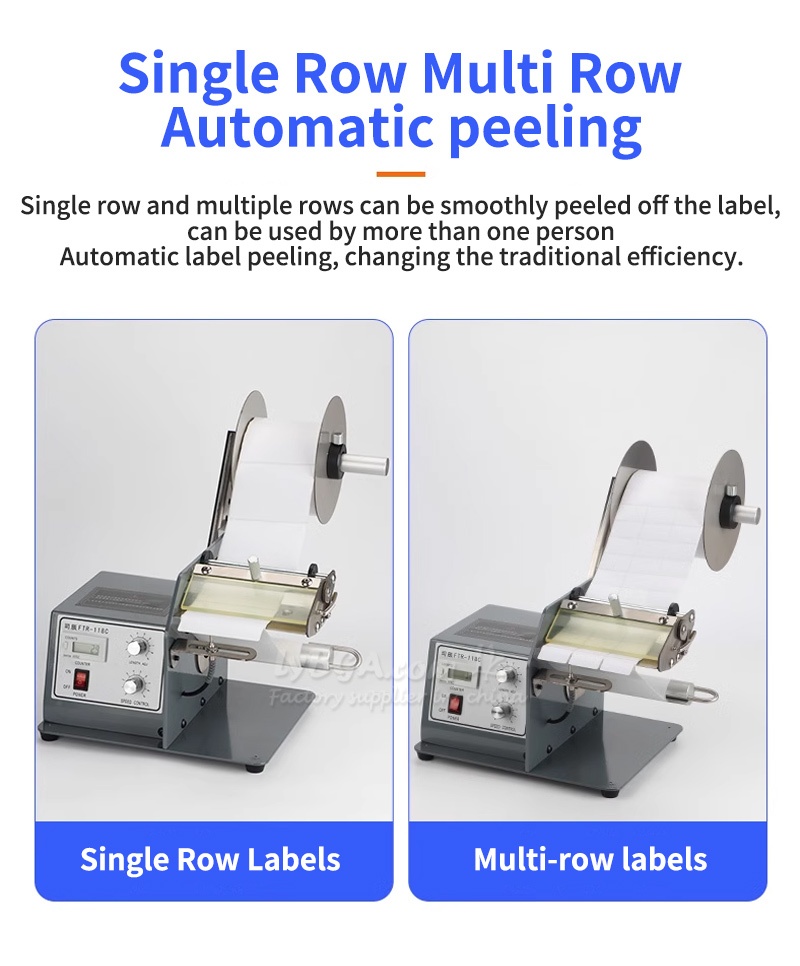

Single Row Multi Row Automatic peeling

Single row and multiple rows can be smoothly peeled off the label, can be used by more than one person. Automatic label peeling, changing the traditional efficiency

Difference between photoelectric and fiber optic

Two types of sensing for you to choose from

Applicable paper labels

Self-adhesive label printing pattern, Hot stamping stickers insulating materials adhesive pads, Laser laser labels stickers and so on

Universal paper labels /transparent labels

PVC transparent adhesive

Bottom reflective labels etc

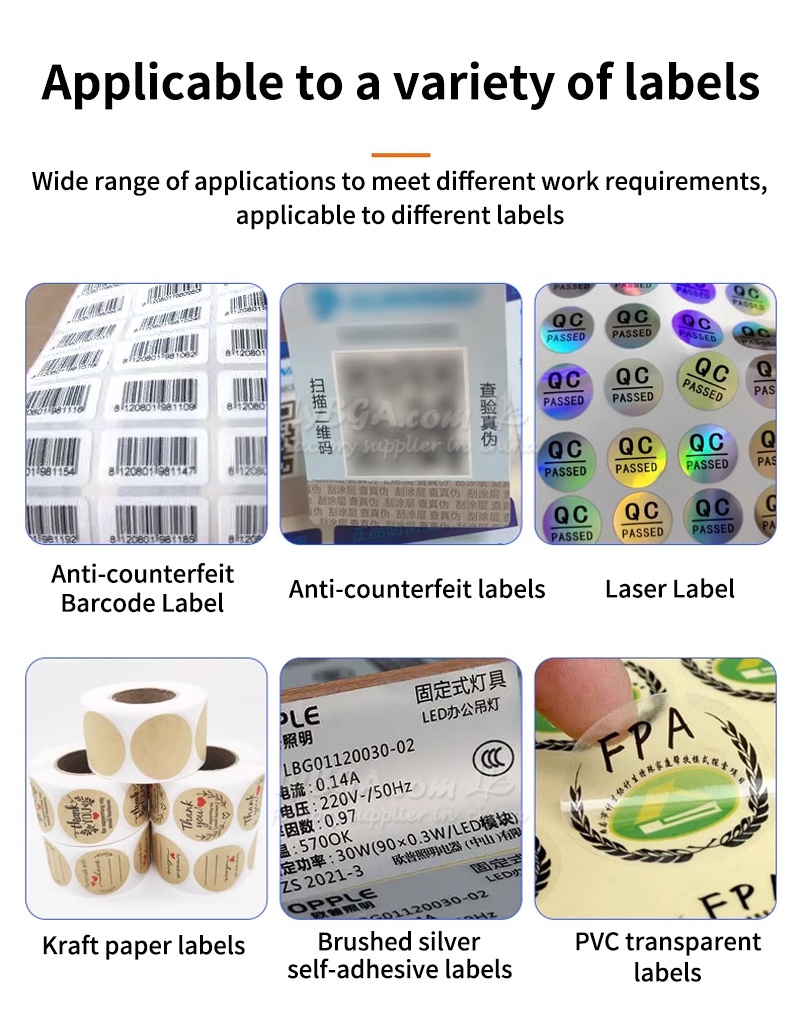

Applicable to a variety of labels

Wide range of applications to meet different work requirements, applicable to different labels

Anti-counterfeit Barcode Label

Anti-counterfeit labels

Laser Label

Kraft paper labels

Brushed silver self-adhesive labels

PVC transparent labels

Product details show

More than cost-effective but also let you rest assured that the automatic label peeling machine

Digital display counting function

You can count at any time, to understand the work situation to master the work rhythm

Scrap spool

After the use of the label backing paper winding complete with a hand wrapped to remove can be

Length speed control

Adjust the speed and length of the label according to the work rhythm

Switching power supply

With a fuse design to prevent burnout safer

Label baffle

Hang the label paper roll, hang the label roll on the label hanging plate and fix it with the positioning plate

Intelligent Sensor Precise labeling

Different sensors, different labels peeled off

Fiber optic/optical sensors are available

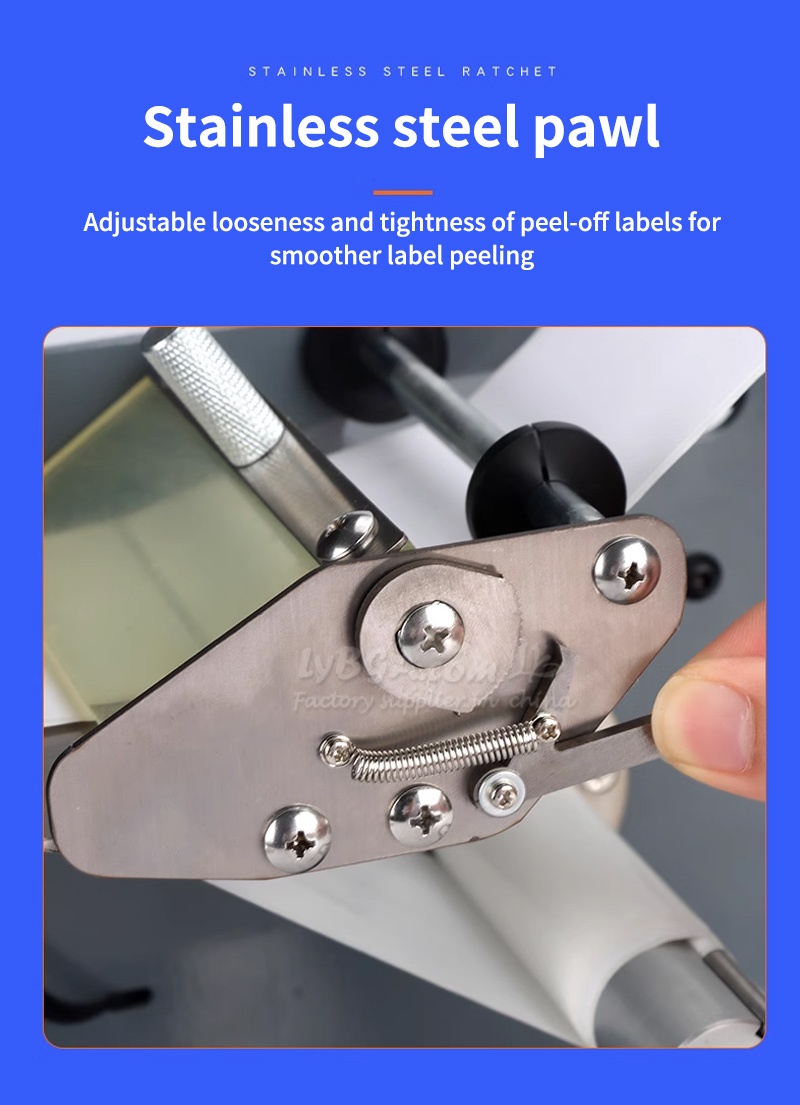

Stainless steel pawl

Adjustable looseness and tightness of peel-off labels for smoother label peeling

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!