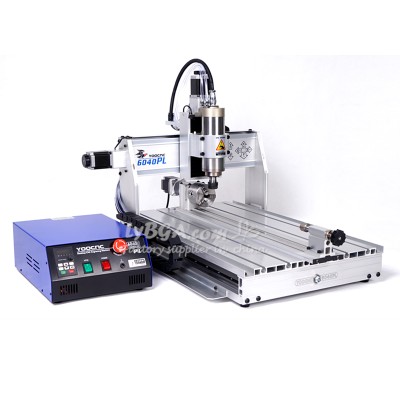

CNC Router Engraving And Cutting Machine LY 6040pl Customized Diy Cutting Optional 3/4 Axis And Flume 2200w Spindle Er20 Collet

Product Detail

Product Tags

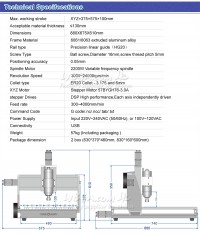

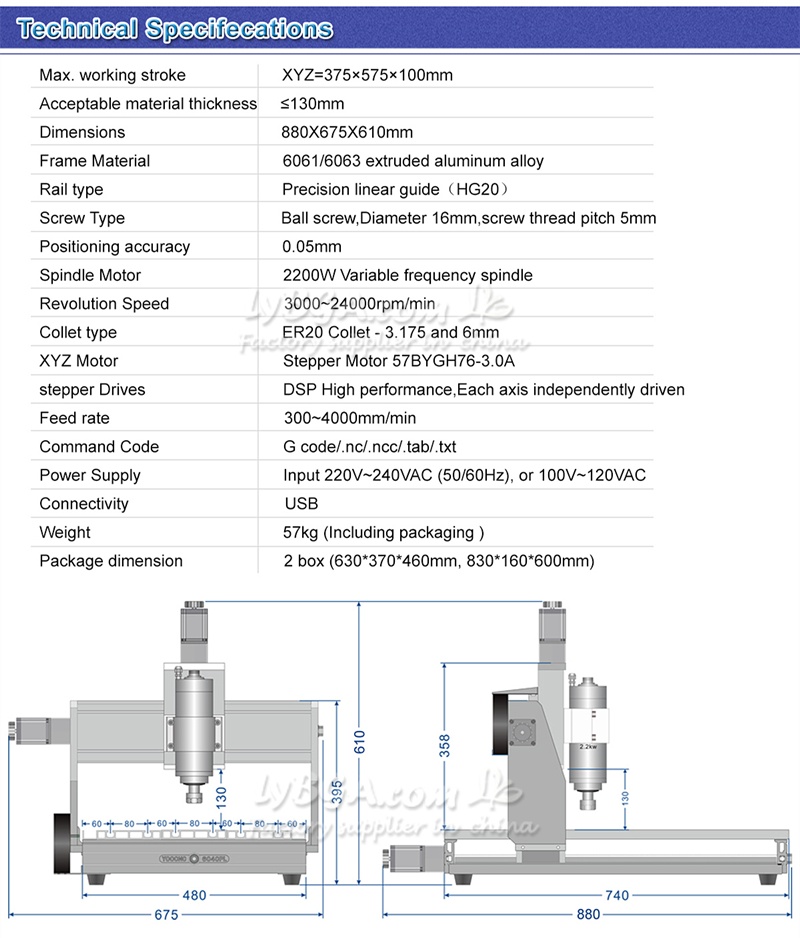

Product Parameters

|

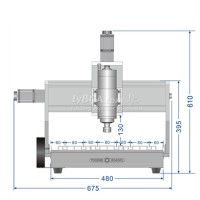

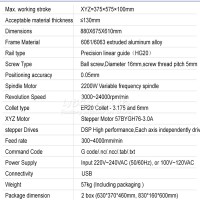

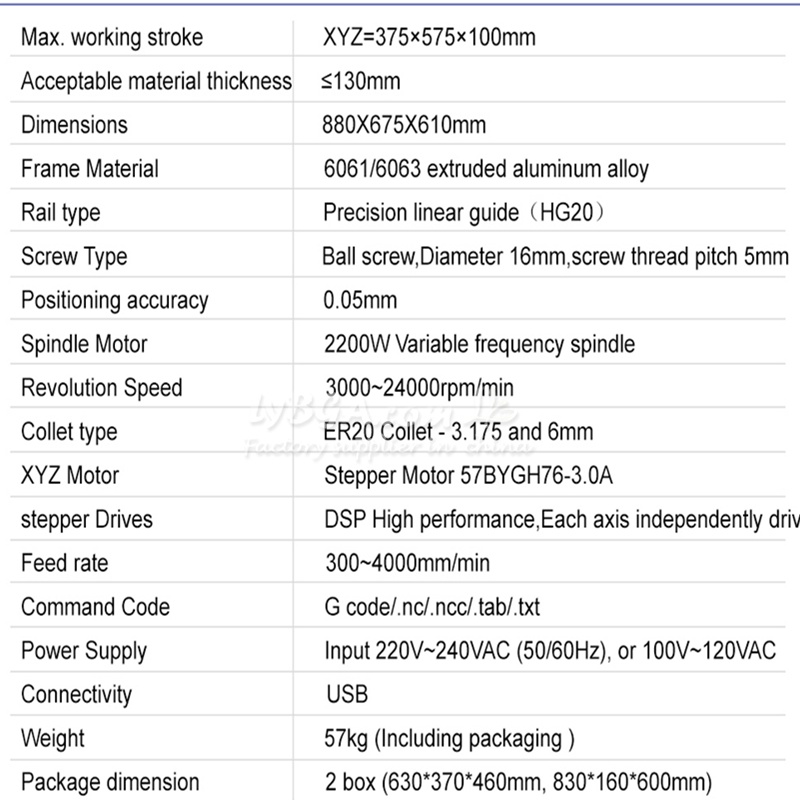

Max. working stroke |

XYZ=375*575*100mm |

|

Acceptable material thickness |

≤130mm |

|

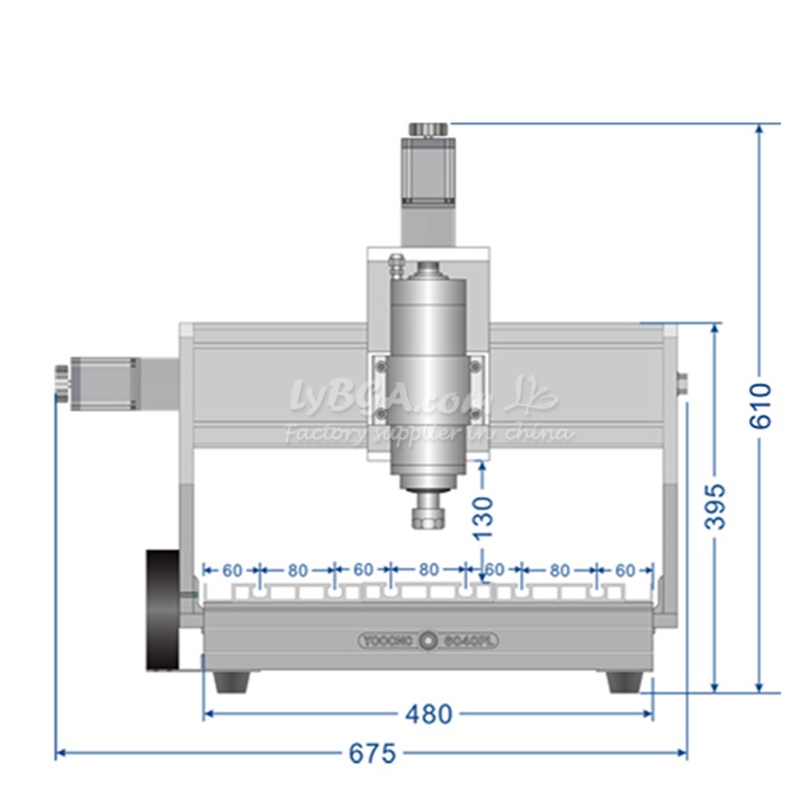

Dimensions |

880*675*610mm |

|

Frame Material |

6061/6063 extruded aluminum alloy |

|

Rail type |

Precision linear guide (HG20) |

|

Screw Type |

Ball screw, Diameter 16mm,screw thread pitch 5mm |

|

Positioning accuracy |

0.05mm |

|

Spindle Motor |

2200W Variable frequency spindle |

|

Revolution Speed |

3000~24000rpm/min |

|

Collet type |

ER20 Collet – 3.175 and 6mm |

|

XYZ Motor |

Stepper Motor 57BYGH76-3.0A |

|

Stepper Drives |

DSP High performance, Each axis independently driven |

|

Feed rate |

300~4000mm/min |

|

Command Code |

G code/nc./ncc./ tab/.txt |

|

Power Supply |

Input 220V~240VAC (50/60Hz), or 100V~120VAC |

|

Connectivity |

USB |

|

Weight |

57kg (Including packaging ) |

|

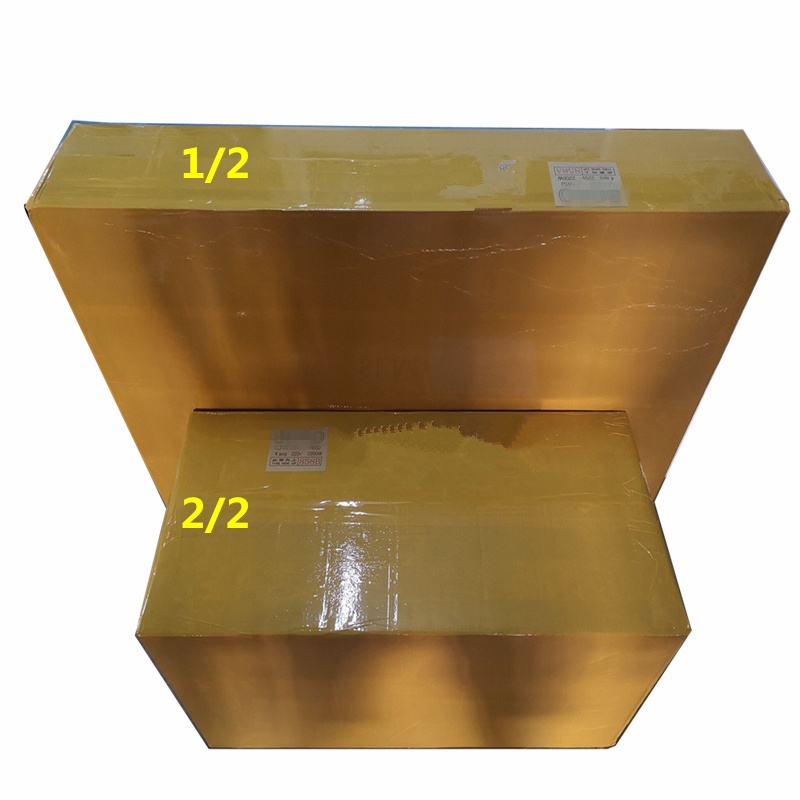

Package dimension |

2 box (630*370*460mm, 830* 160*600mm) |

Detail page text

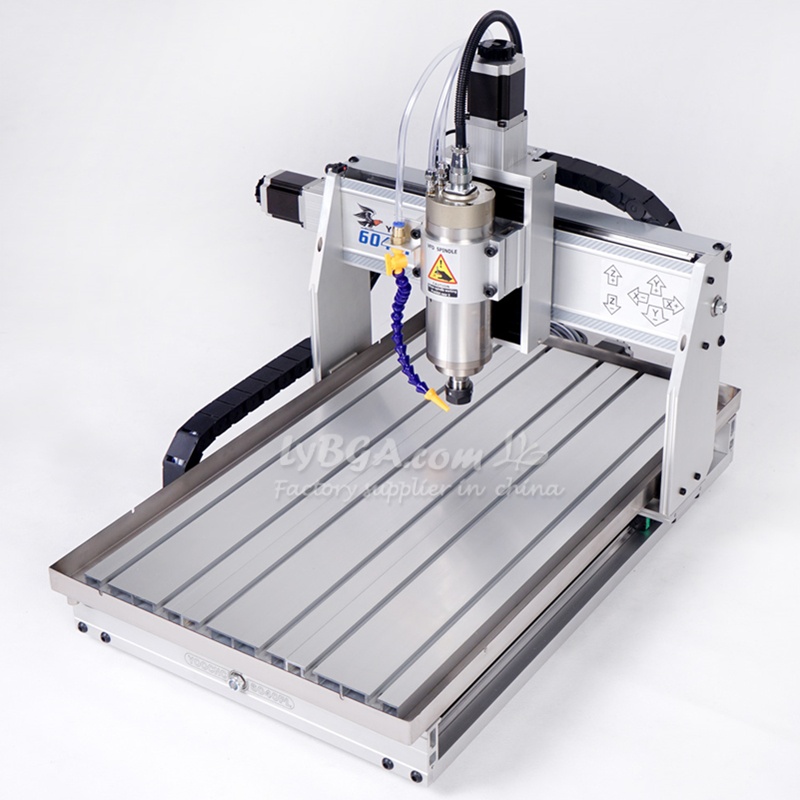

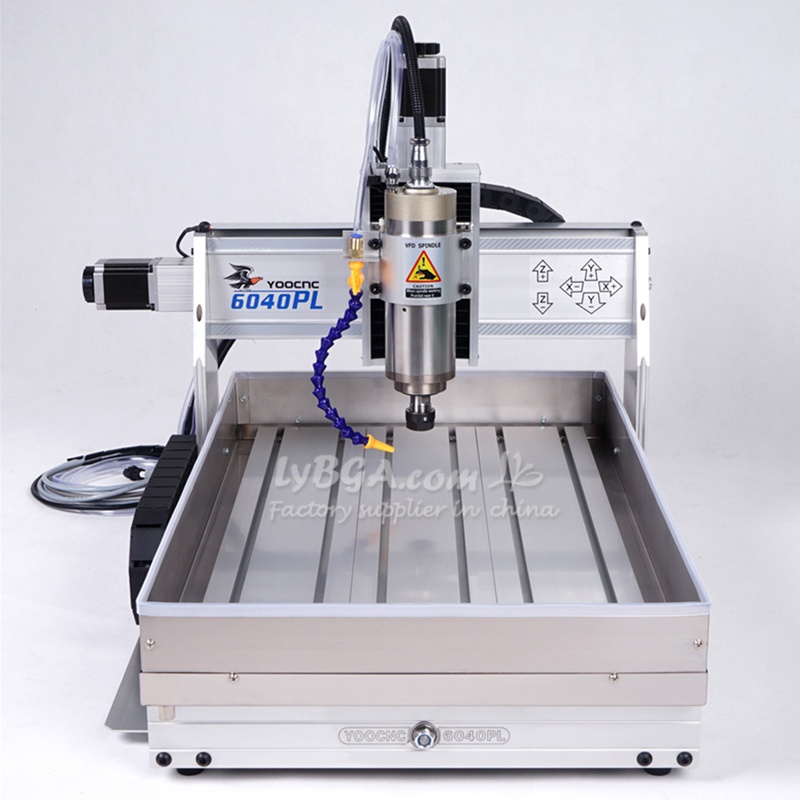

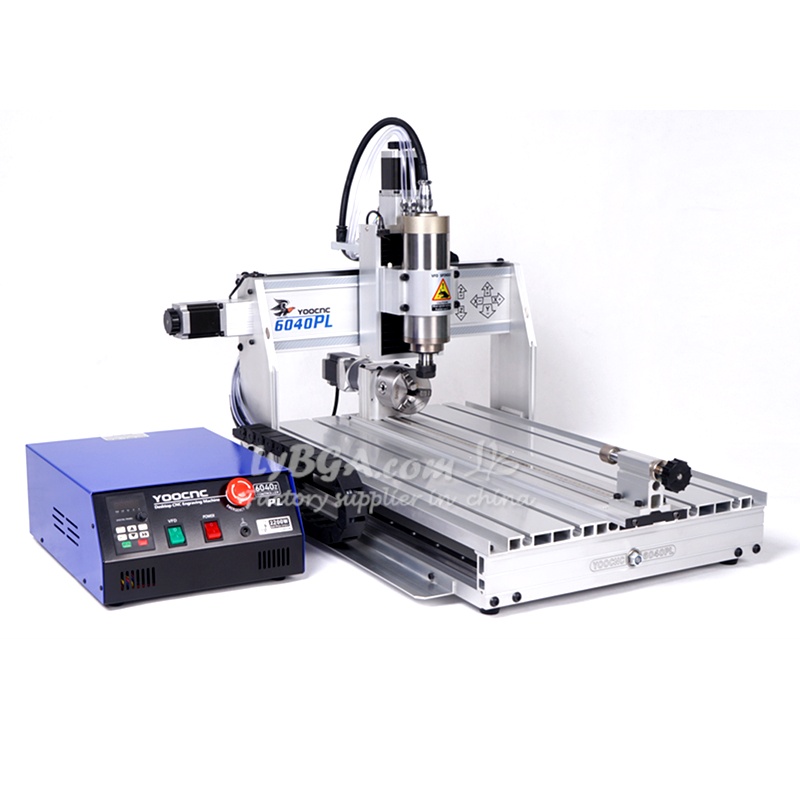

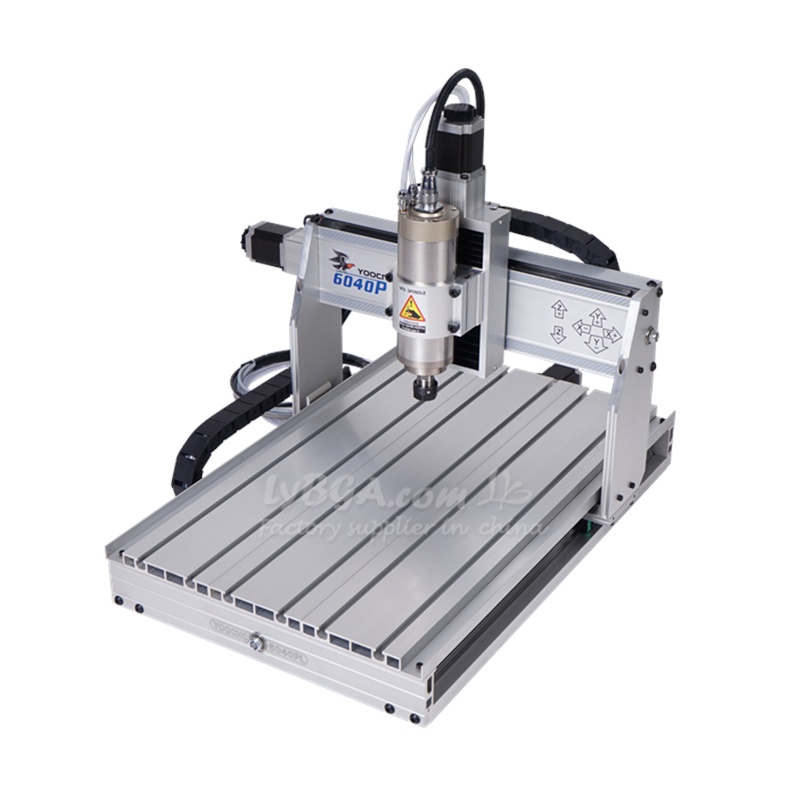

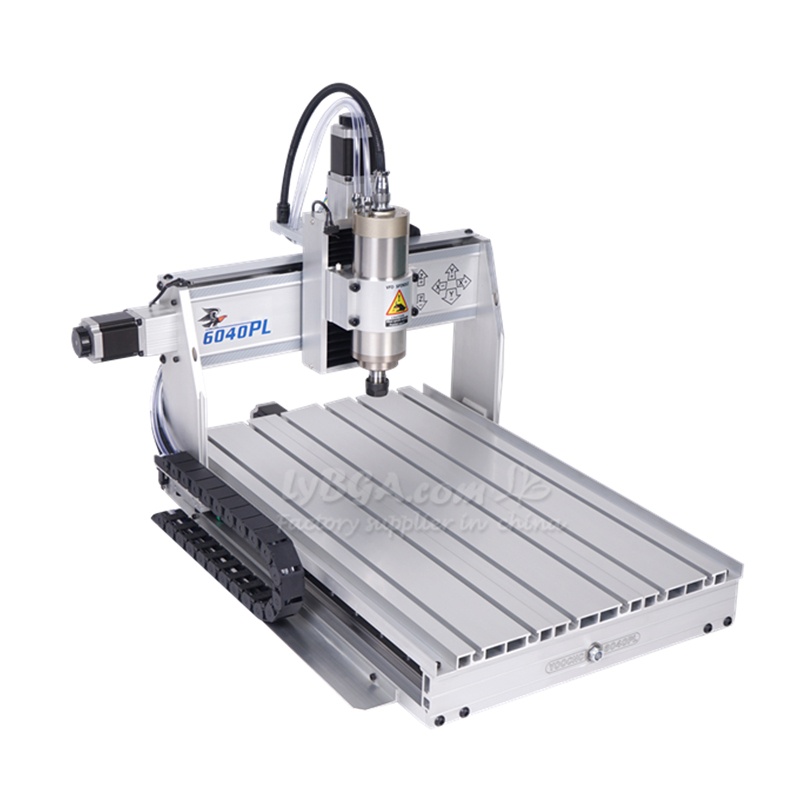

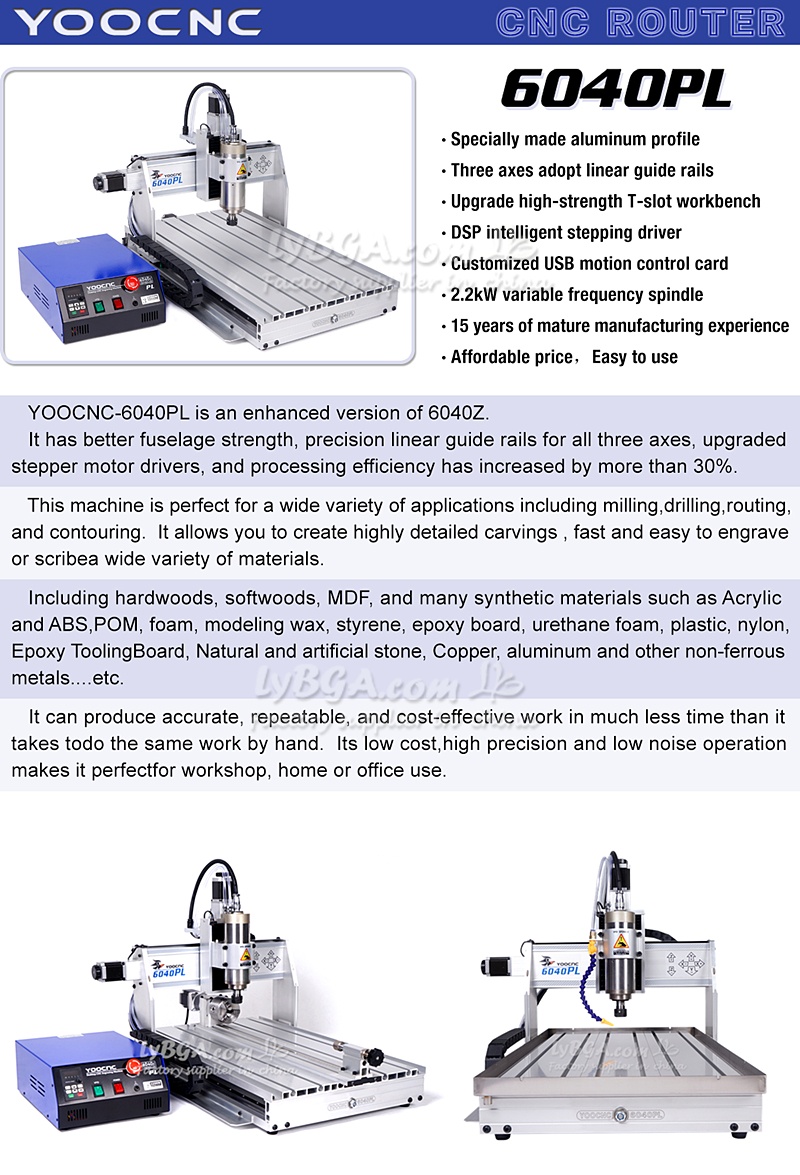

6040PL CNC ROUTER

●Specially made aluminum profile

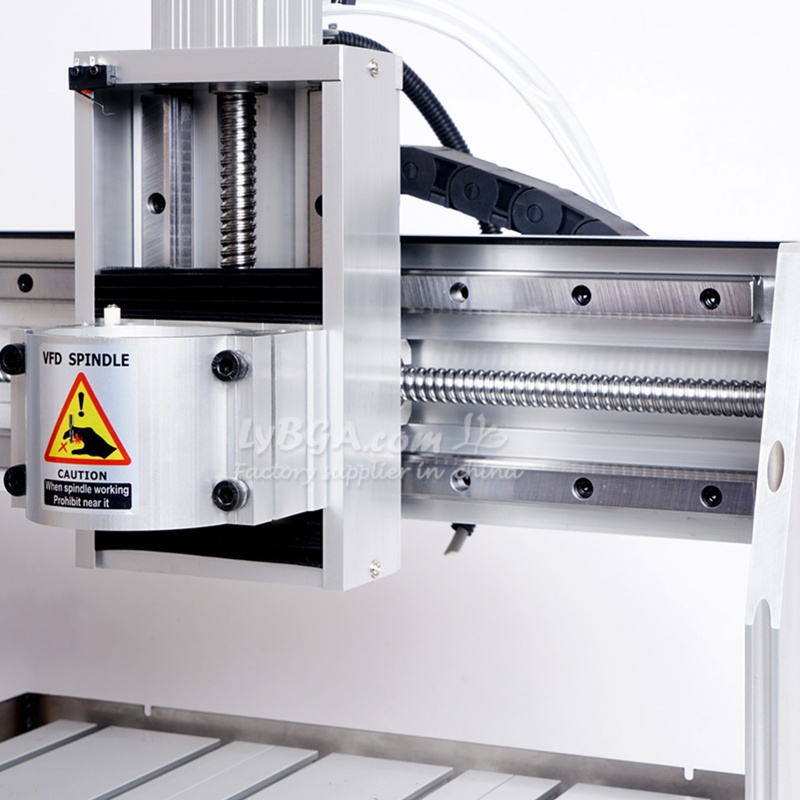

●Three axes adopt linear guide rails

●Upgrade high-strength T-slot workbench

●DSP intelligent stepping driver

●Customized USB motion control card

●2.2kW variable frequency spindle

●15 years of mature manufacturing experience

●Affordable price,Easy to use

6040PL is an enhanced version of 6040Z.

It has better fuselage strength, precision linear guide rails for all three axes, upgraded stepper motor drivers, and processing efficiency has increased by more than 30%.

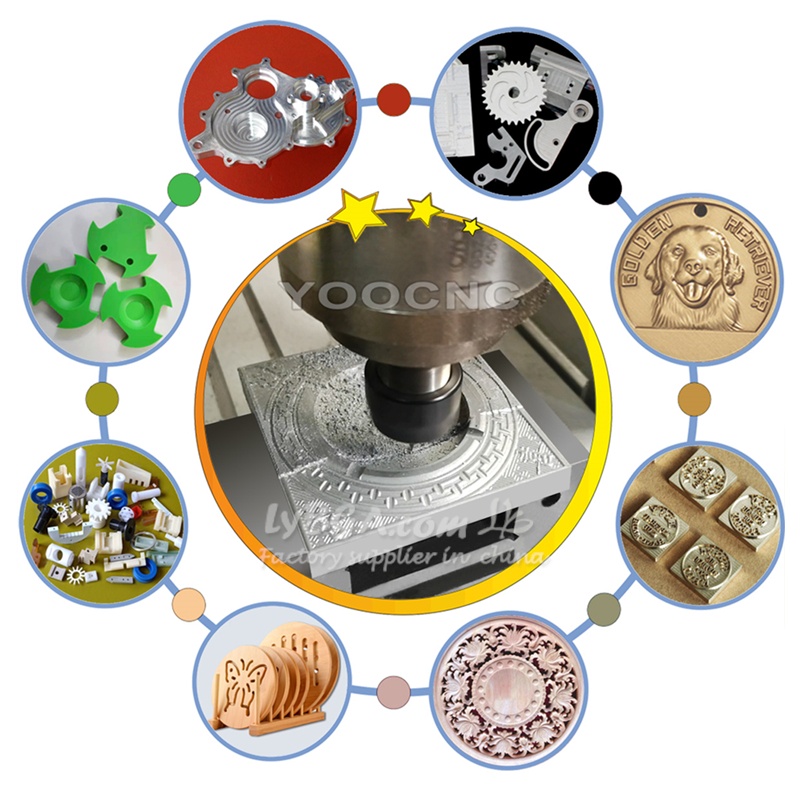

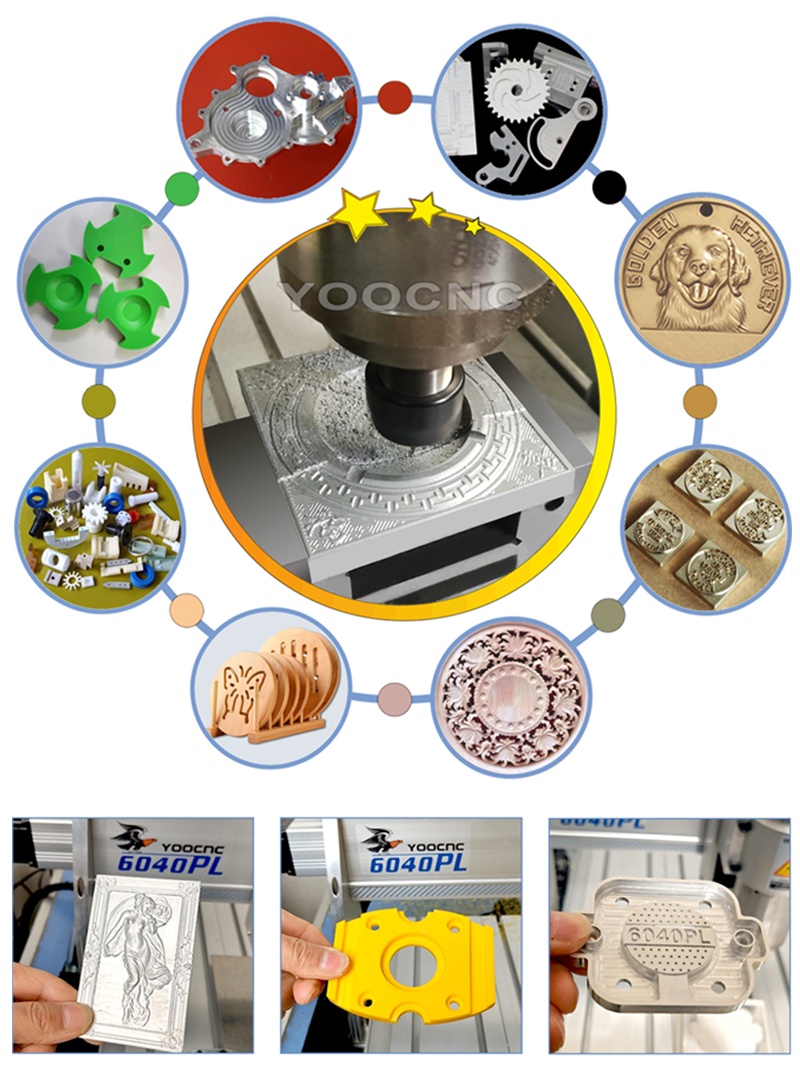

This machine is perfect for a wide variety of applications including milling, dilling, routing, and contouring. It allows you to create highly detailed carvings,fast and easy to engrave or scribea wide variety of materials.

Including hardwoods, softwoods, MDF, and many synthetic materials such as Acrylic and ABS,POM, foam, modeling wax, styrene, epoxy board, urethane foam, plastic, nylon, Epoxy Tooling Board, Natural and artificial stone, Copper, aluminum and other non-ferrous metals…etc.

It can produce accurate, repeatable, and cost- effective work in much less time than it takes todo the same work by hand. Its low cost, high precision and low noise operation makes it perfectfor workshop, home or office use.

The pursuit of quality the pursuit of Excellence

Premium linear motion components (linear guide rails, precision ball screw)

Rigid al-metal design (heavy-duty aluminum extrusion)

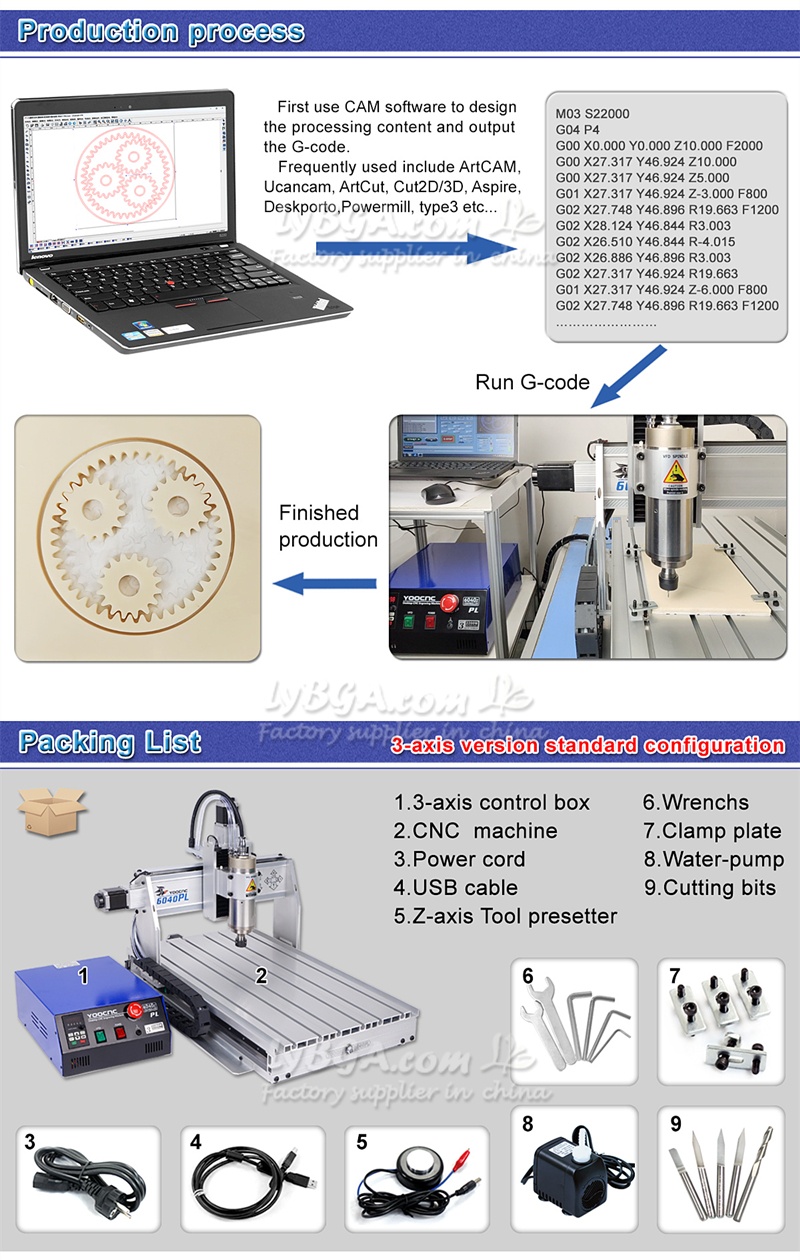

Packing List

3-axis version standard configuration

1.3-axis control box

2. CNC machine

3. Power cord

4.USB cable

5. Z-axis Tool presetter

6. Wrenchs

7. Clamp plate

8. Water-pump

9. Cutting bits

Optional-1: Fourth axis (rotary axis)

Specification

●80mm 3 jaw chuck

●Nema 24 stepper motor, 2 PHASE 11.8″STEP/3.5A

●Center height: H= 60mm

●Max swing diameter: S1 10mm

●Deceleration method: Planetary gear reduction

●Maximum RPM: 160

●Weight: 7kg

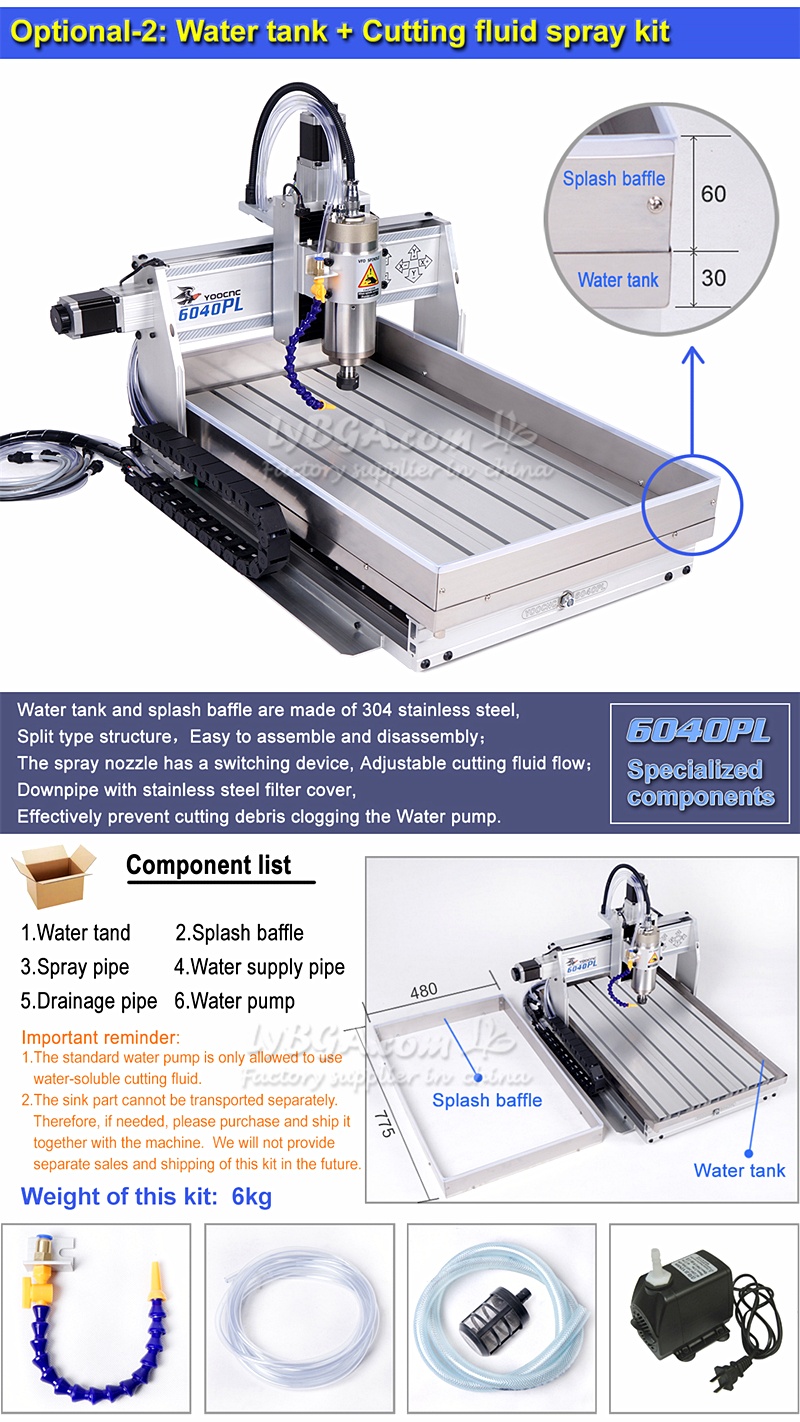

Optional-2: Water tank + Cutting fluid spray kit

6040PL Specialized components

●Water tank and splash baffle are made of 304 stainless steel,

●Split type structure, Easy to assemble and disassembly;

●The spray nozzle has a switching device, Adjustable cutting fluid flow;

●Downpipe with stainless steel filter cover,

●Effectively prevent cutting debris clogging the Water pump.

Component list

1.Water tand

2.Splash baffle

3.Spray pipe

4.Water supply pipe

5.Drainage pipe

6.Water pump

Important reminder:

1.The standard water pump is only allowed to use water-soluble cutting fluid.

2.The sink part cannot be transported separately. Therefore, if needed, please purchase and ship it together with the machine. We will not provide separate sales and shipping of this kit in the future.

Weight of this kit: 6kg

Production process

First use CAM software to design the processing content and output the G-code.

Frequently used include ArtCAM, Ucancam, ArtCut, Cut2D/3D, Aspire, Deskporto, Powermill, type3 ete…→ Run G-code →Finished production

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!