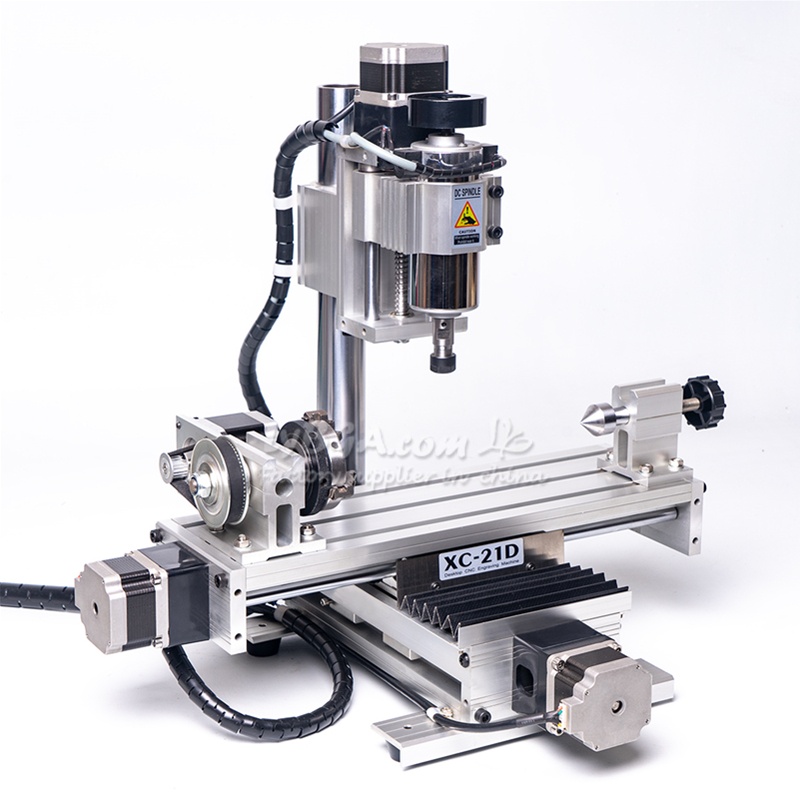

CNC Engraving And Cutting Machine LY XC-21D Customized Diy Cutting Optional 3/4 Axis 300w Dc Spindle Er11 Collet

Product Detail

Product Tags

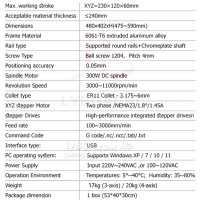

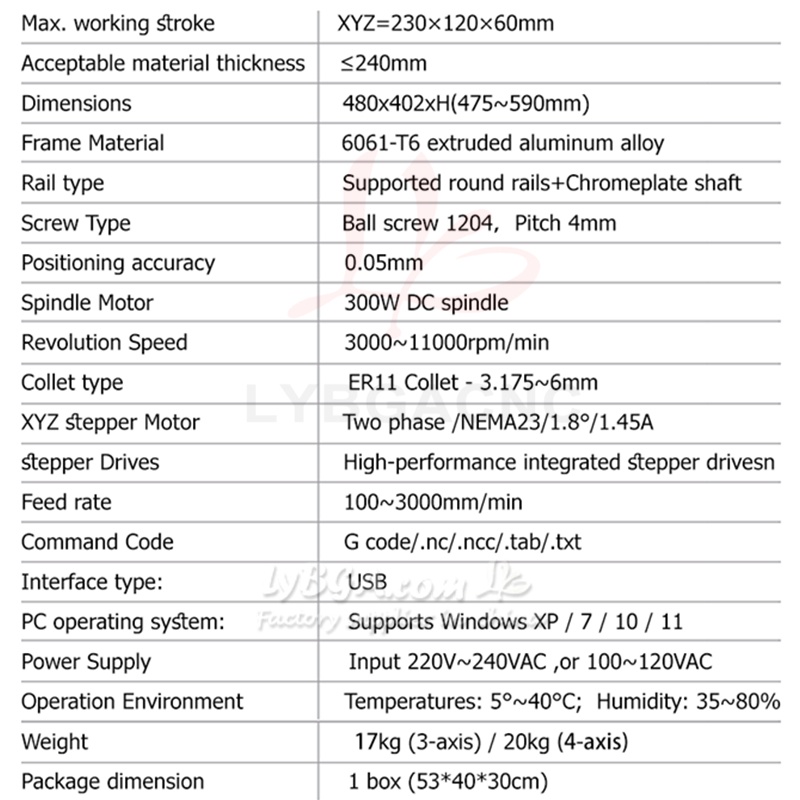

Equipment parameters

|

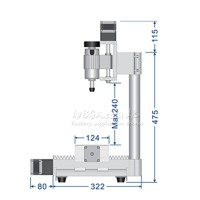

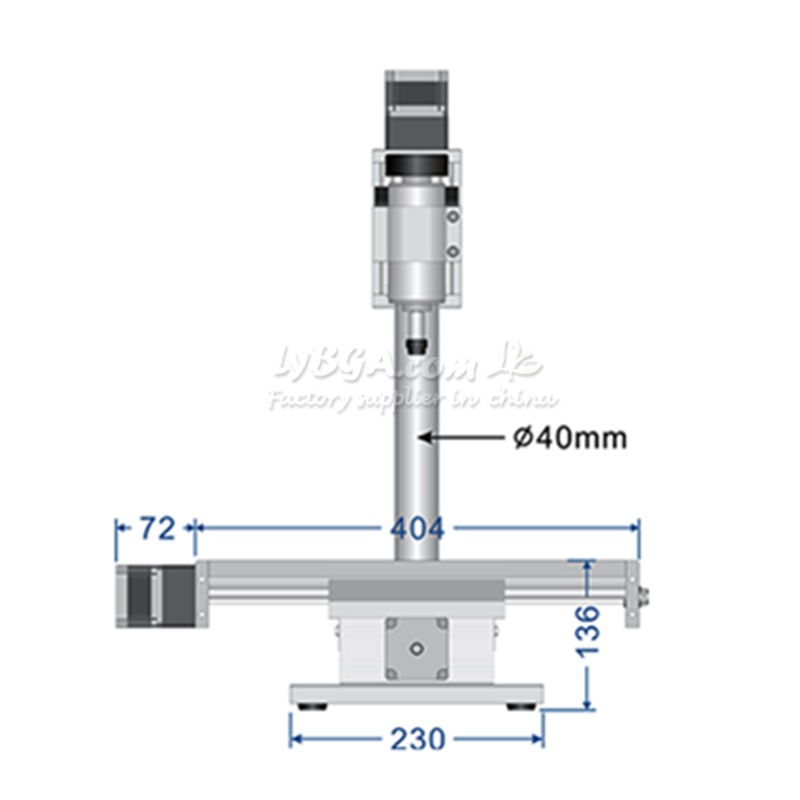

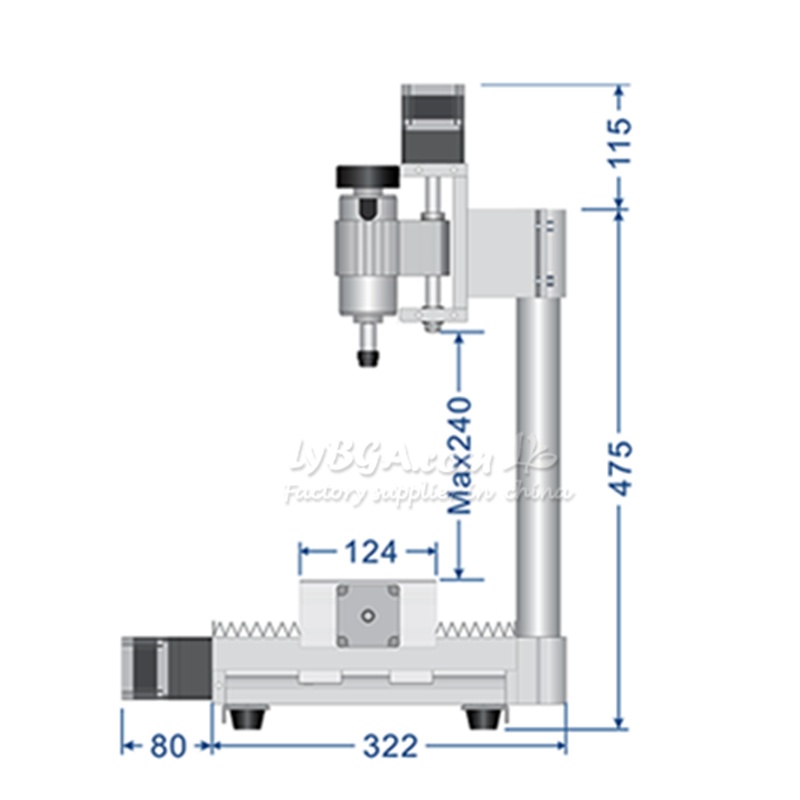

Max. working stroke |

XYZ=230*120*60mm |

|

Acceptable material thickness |

≤240mm |

|

Dimensions |

480*402*H(475~590mm) |

|

Frame Material |

6061-T6 extruded aluminum alloy |

|

Rail type |

Supported round rails+ Chromeplate shaft |

|

Screw Type |

Ball screw 1204,Pitch 4mm |

|

Positioning accuracy |

0.05mm |

|

Spindle Motor |

300W DC spindle |

|

Revolution Speed |

3000~ 11000rpm/min |

|

Collet type |

ER11 Collet – 3.175~6mm |

|

XYZ stepper Motor |

Two phase /NEMA23/1.89/1.45A |

|

stepper Drives |

High-performance integrated stepper drives |

|

Feed rate |

100~3000mm/min |

|

Command Code |

G code/.nc/ .ncc/ .tab/.txt |

|

Interface type: |

USB |

|

PC operating system: |

Supports Windows XP/ 7 / 10/ 11 |

|

Power Supply |

Input 220V~240VAC ,or 100~ 120VAC |

|

Operation Environment |

Temperatures: 5°~40°C; Humidity: 35~80% |

|

Weight |

17kg (3-axis) I 20kg (4-axis) |

|

Package dimension |

1 box (53*40*30cm) |

Detail page text

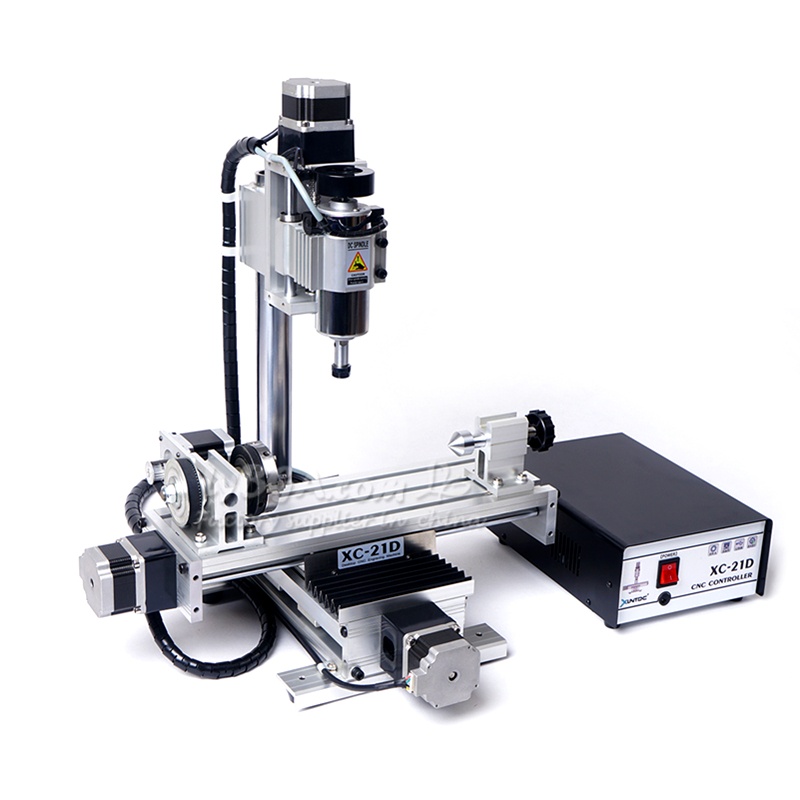

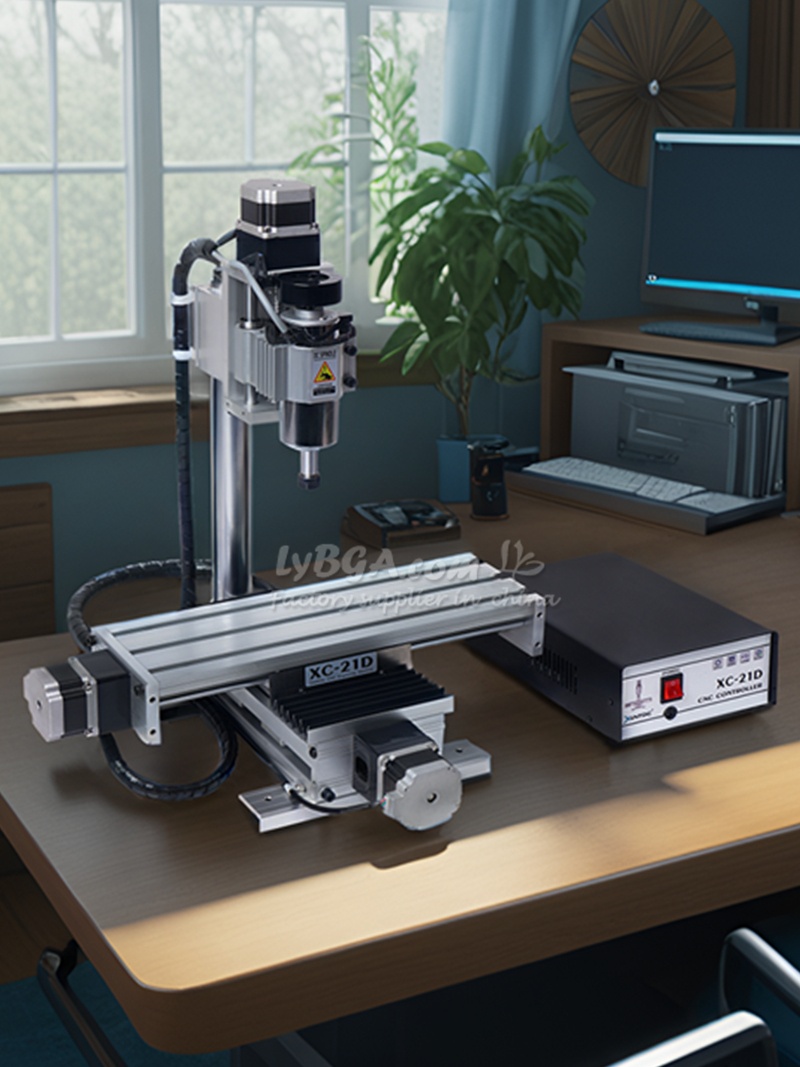

XC-21D MINI CNC ENGRAVING MACHINES

Your Gateway to Precision DIY & CNC Learning

The XC-21D is an entry-level CNC engraving machine designed for makers, educators, and beginners who value compact size, affordability, and hands-on learning. With a footprint no larger than 0.2m², it fits seamlessly into home workshops, classrooms, or makerspaces.

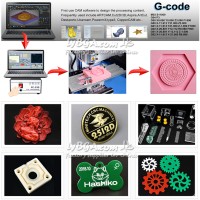

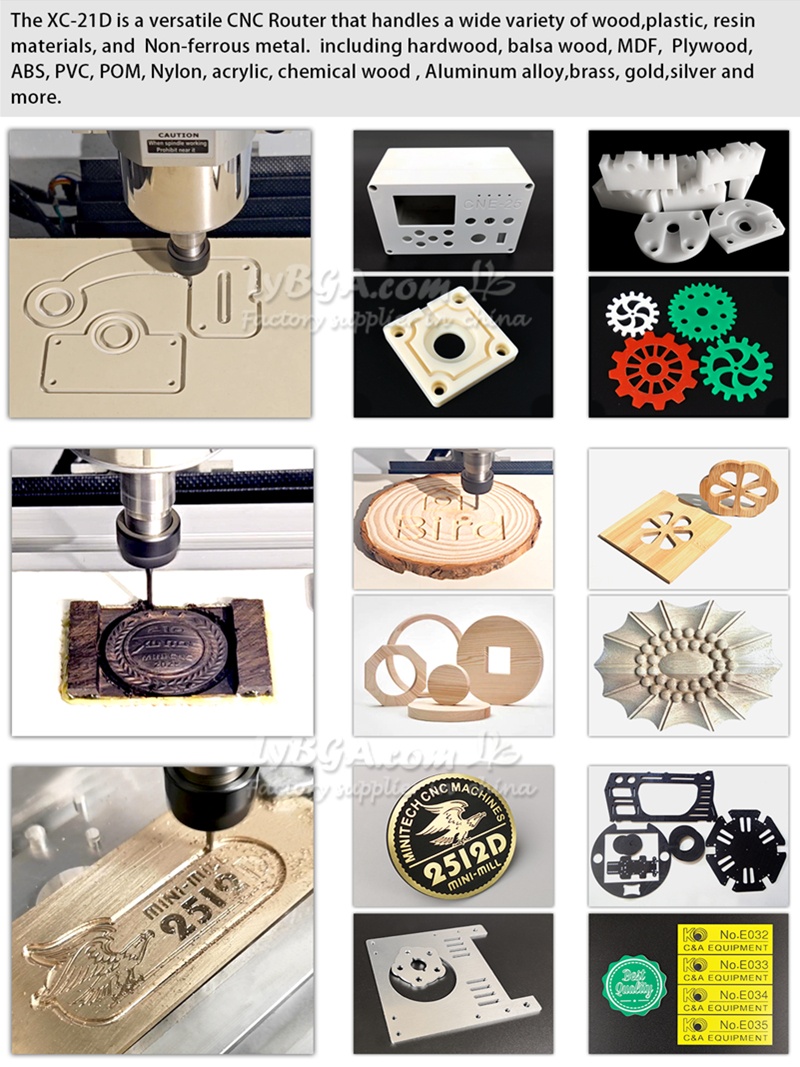

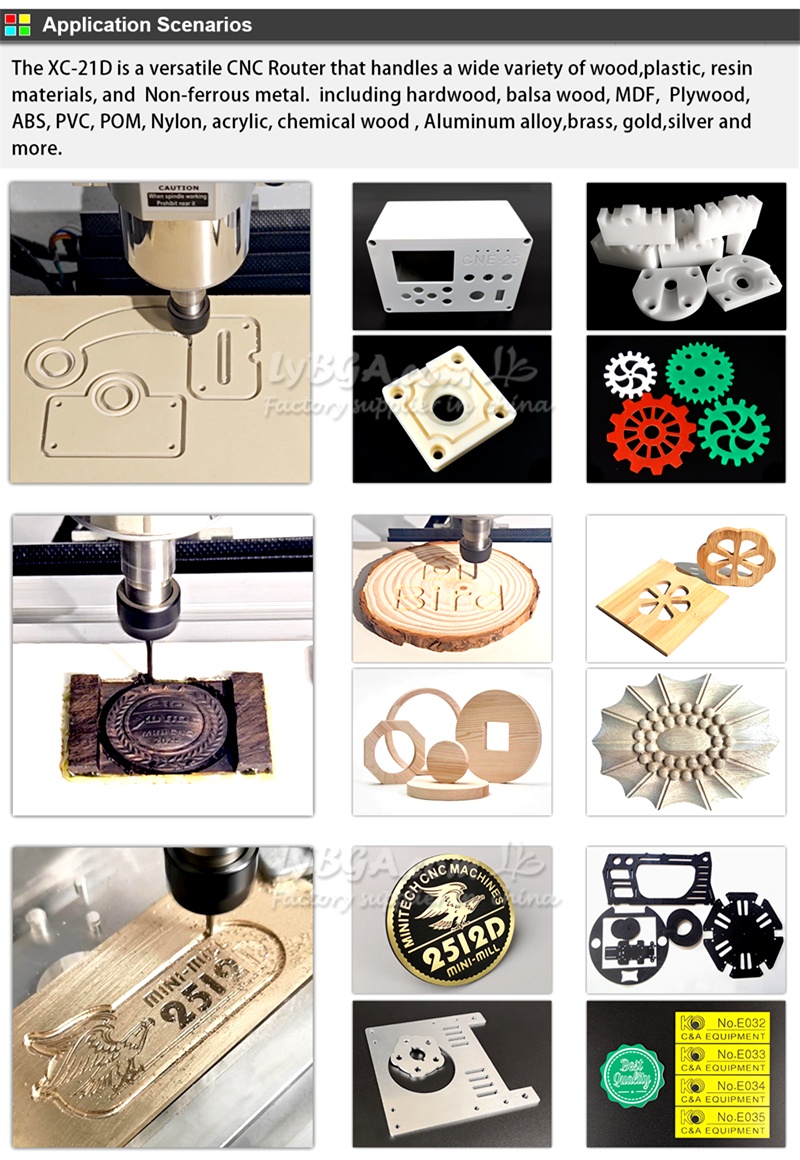

Application Scenarios

The XC-21D is a versatile CNC Router that handles a wide variety of wood, plastic, resin materials, and Non-ferrous metal. including hardwood, balsa wood, MDF, Plywood, ABS, PVC, POM, Nylon, acrylic, chemical wood,Aluminum alloy, brass, gold, silver and more. .

Key Features

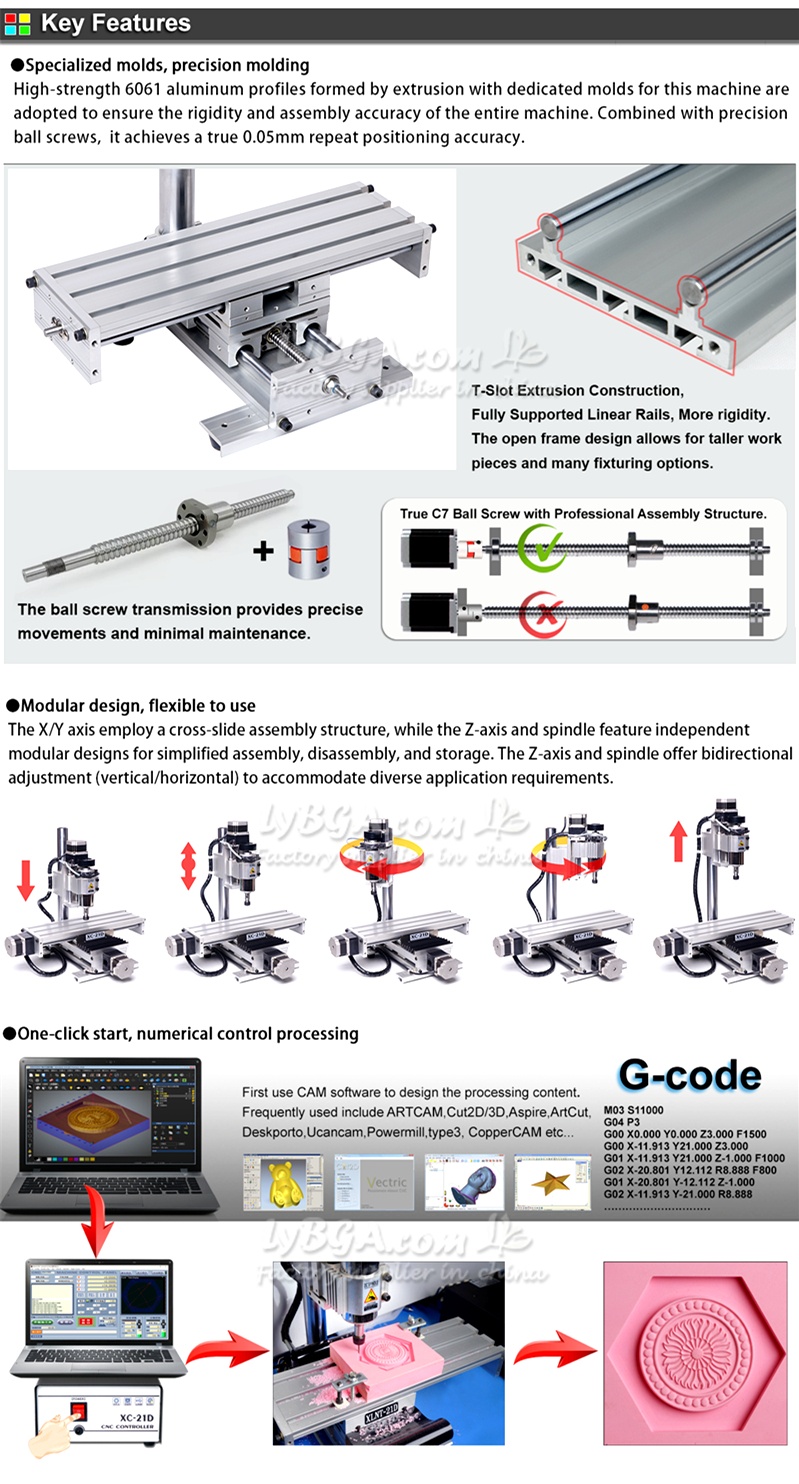

●Specialized molds, precision molding

High-strength 6061 aluminum profiles formed by extrusion with dedicated molds for this machine are adopted to ensure the rigidity and assembly accuracy of the entire machine. Combined with precision ball screws, it achieves a true 0.05mm repeat positioning accuracy.

T-Slot Extrusion Construction, Fully Supported Linear Rails, More rigidity. The open frame design allows for taller work pieces and many fixturing options.

The ball screw transmission provides precise movements and minimal maintenance.

True C7 Ball Screw with Professional Assembly Structure

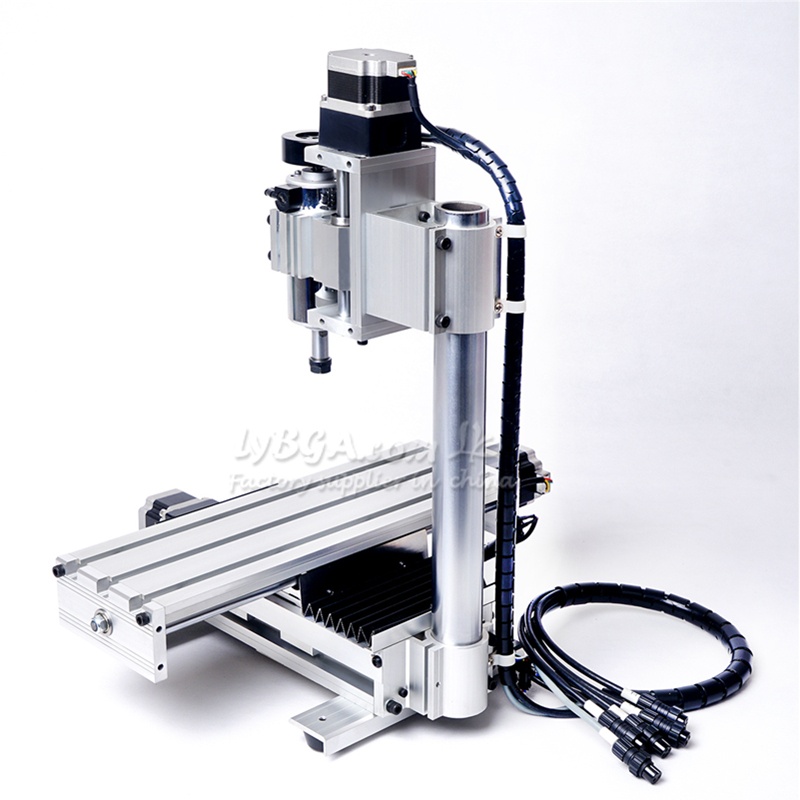

●Modular design, flexible to use

The X/Y axis employ a cross-slide assembly structure, while the Z-axis and spindle feature independent modular designs for simplified assembly, disassembly, and storage. The Z-axis and spindle offer bidirectional adjustment (vertical/horizontal) to accommodate diverse application requirements.

●One-click start, numerical control processing

First use CAM software to design the processing content. Frequently used include ARTCAM, Cut 2D/3D,Aspire,ArtCut, Deskporto, Ucancam, Powermill,type3, CopperCAM etc…

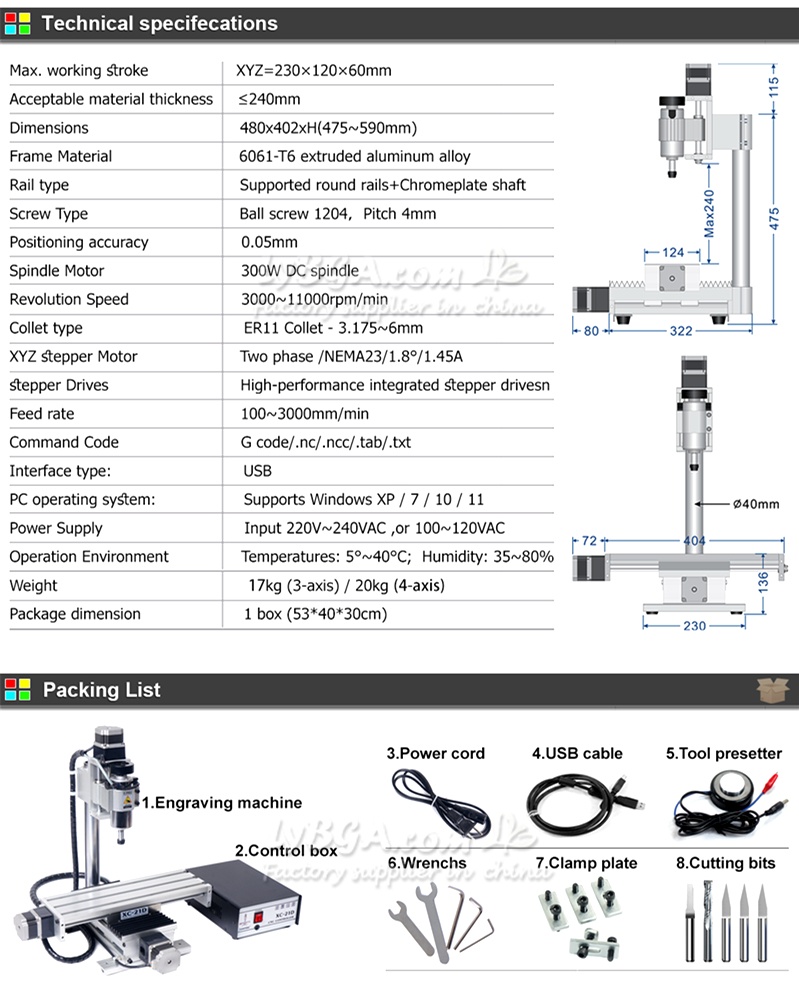

Packing List

1. Engraving machine

2. Control box

3. Power cord

4. USB cable

5. Tool presetter

6.Wrenchs

7 .Clamp plate

8. Cutting bits

Optional components: Rotary axis ( fourth axis )

●Center height: H = 50mm

●Clamping Range: ≤50mm

●Reduction ratio: 3:1

●Maximum RPM: 150

●Maximum turning diameter:≤95mm

●Stepper motor: NEMA23-2 5A

●Three-jaw handscrews chuck Size: 63mm

●Weight: 2.8kg

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!