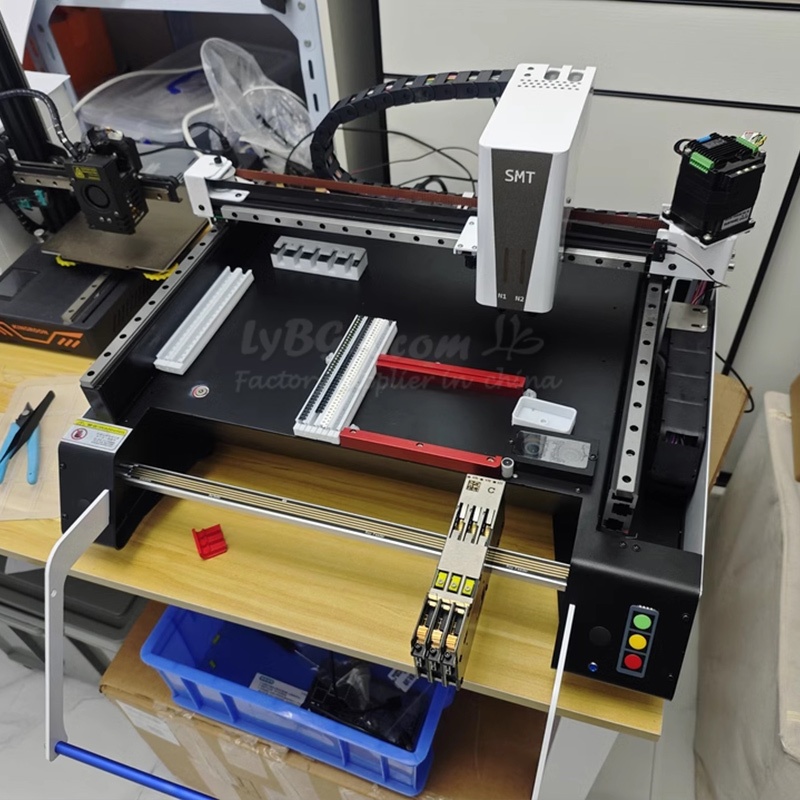

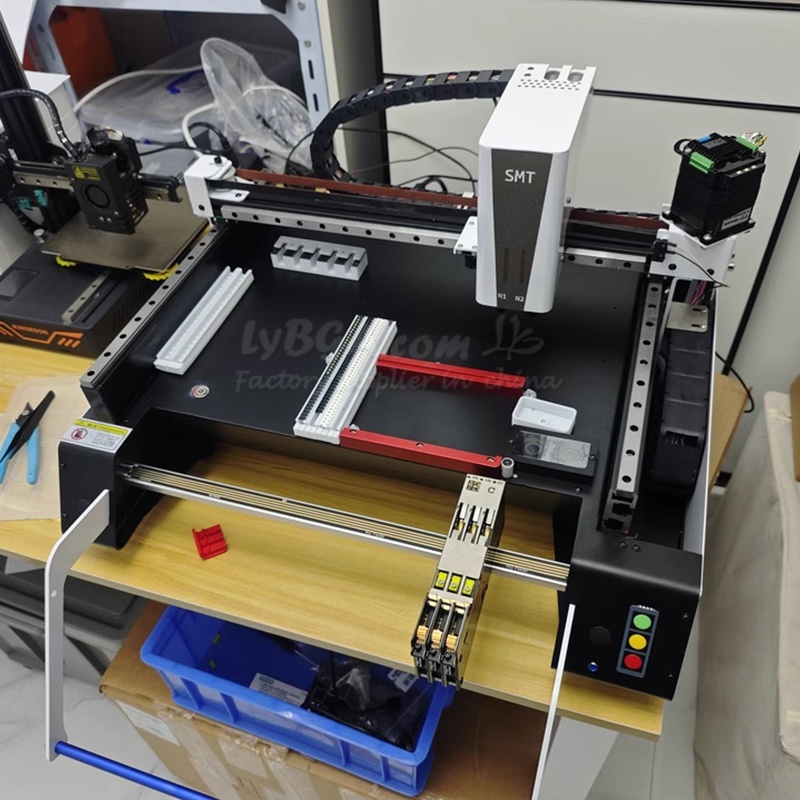

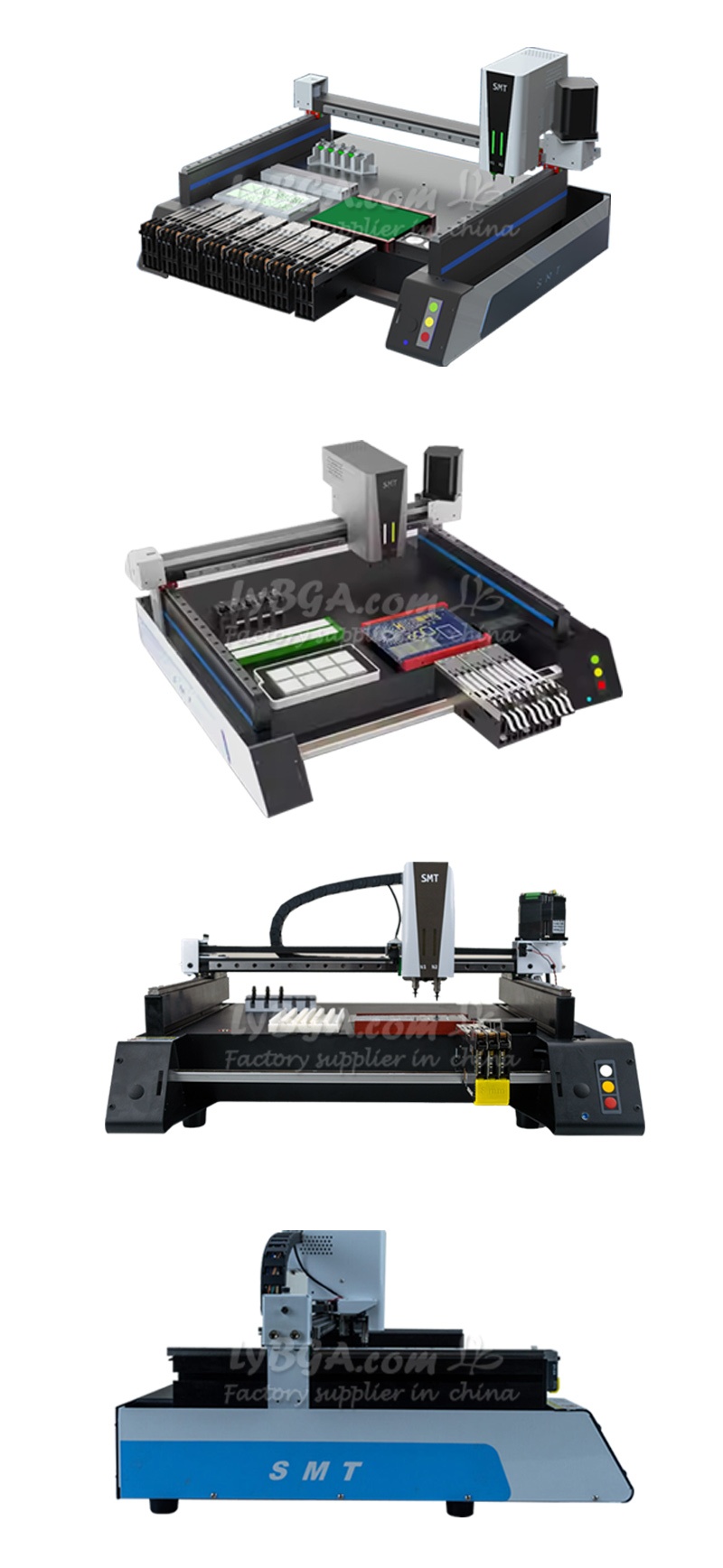

Mini Triple Vision Automatic SMT Pick And Place Machine Chip Mounter LED SMD LY-K1/K1-PRO Camera System For PCB Assembly Line

Product Detail

Product Tags

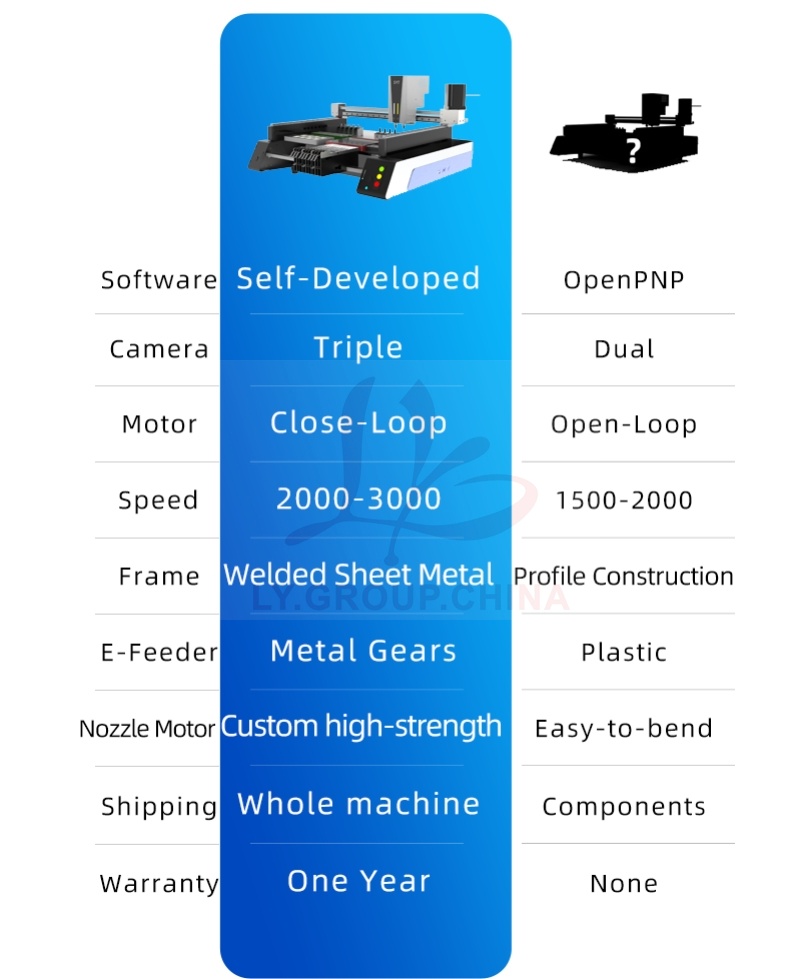

Main difference between K1 & K1 Pro:

- K1: Dual Normal Cameras

K1 Pro: Single High-Speed Camera

2.K1 Max Speed: 3000pcs/Min

K1-Pro Max Speed: 4000pcs/Min

- 1. Overview

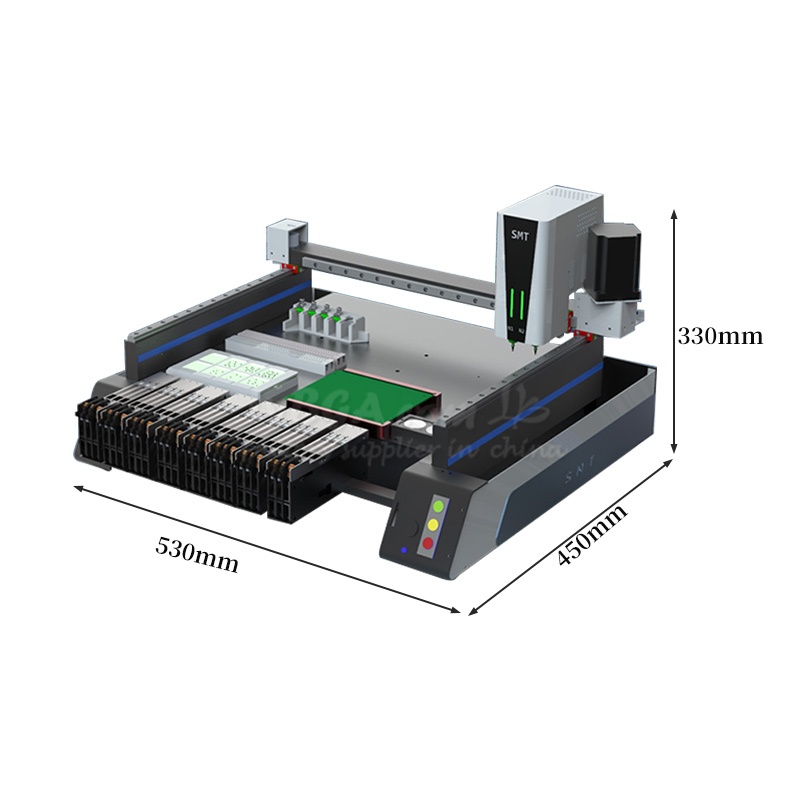

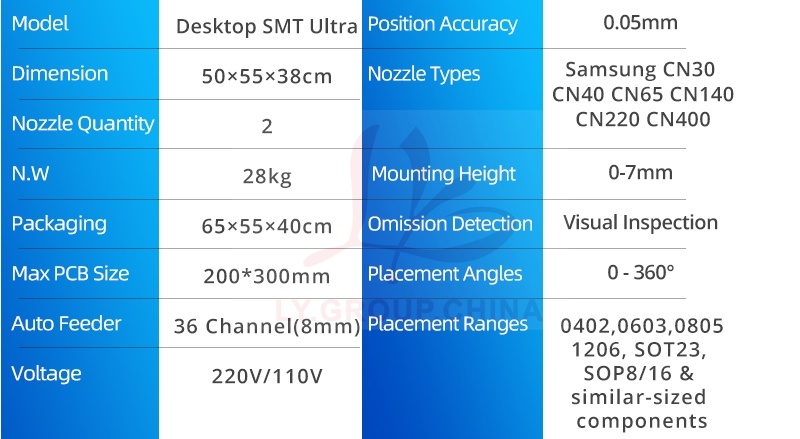

It is an advanced desktop pick-and-place machine designed for precise and efficient PCB assembly. With a three-vision camera system, automatic feeders, and dual placement heads.

Its compact design suits both home and professional environments, offering intelligent, high-speed features for small-scale prototyping and diverse production needs.

*Work flow: 1) Solder paste printing/dispensing solder paste 2) SMT 3) Reflow soldering.

- 2. Feature

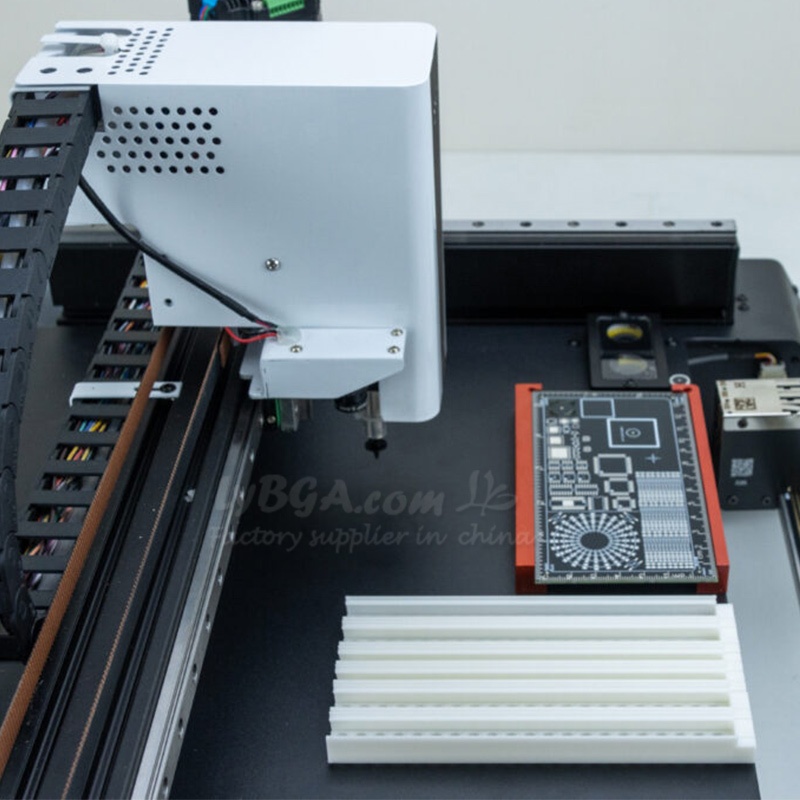

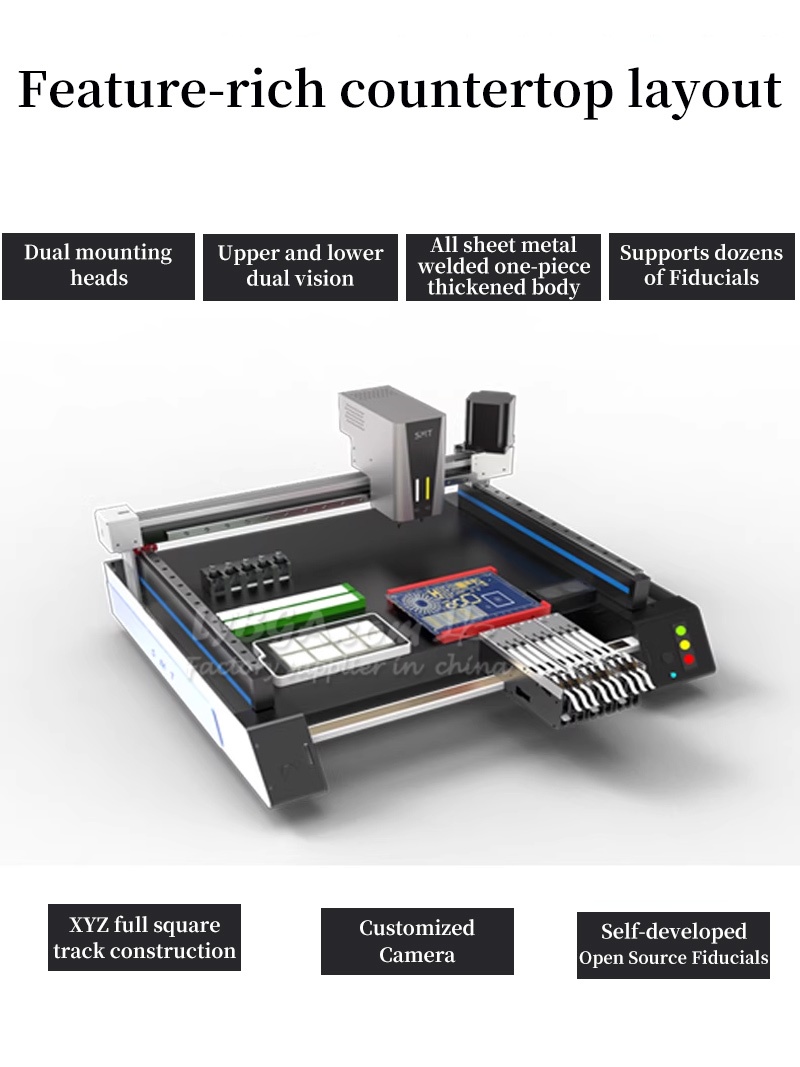

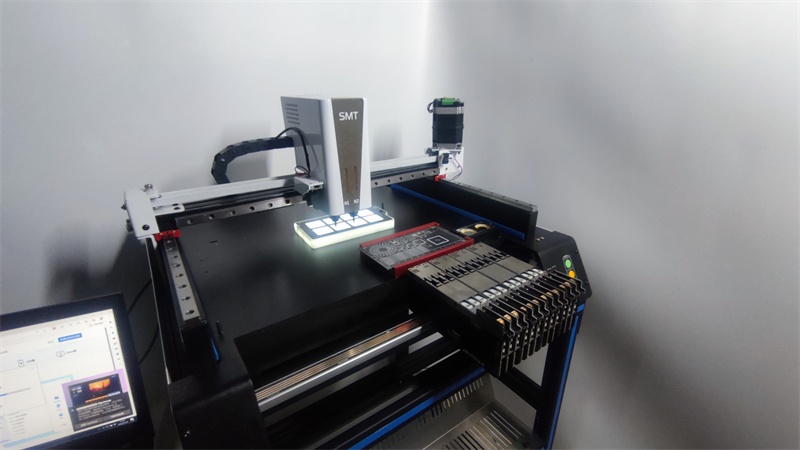

2.1. High Precision: Simultaneous top and bottom camera capture, with up to three cameras on the machine. Closed-loop stepper motor control ensures stability with no missed steps. Custom nozzle motor is durable, and the linear guide structure ensures smooth movement.

2.2. Fast & Efficient: Thanks to powerful S-curve motion control, speed is 80% faster thansimilar machines, with a maximum placement speed of up to 3000 CPH, ensuring stabilityand minimal vibration.

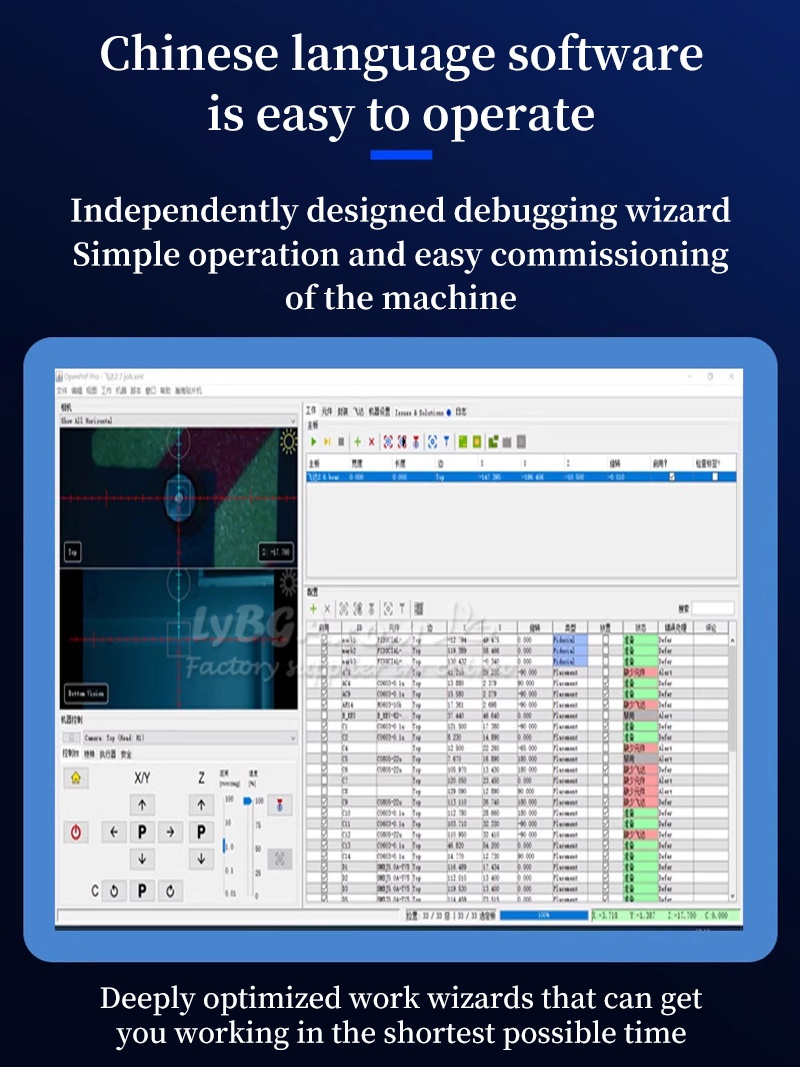

2.3. Easy Operation: Proprietary intelligent placement software with a simple interface andclear logic. Guided tutorial-style help files are available. Supports passive automatic headchange and multiple types of Mark recognition.

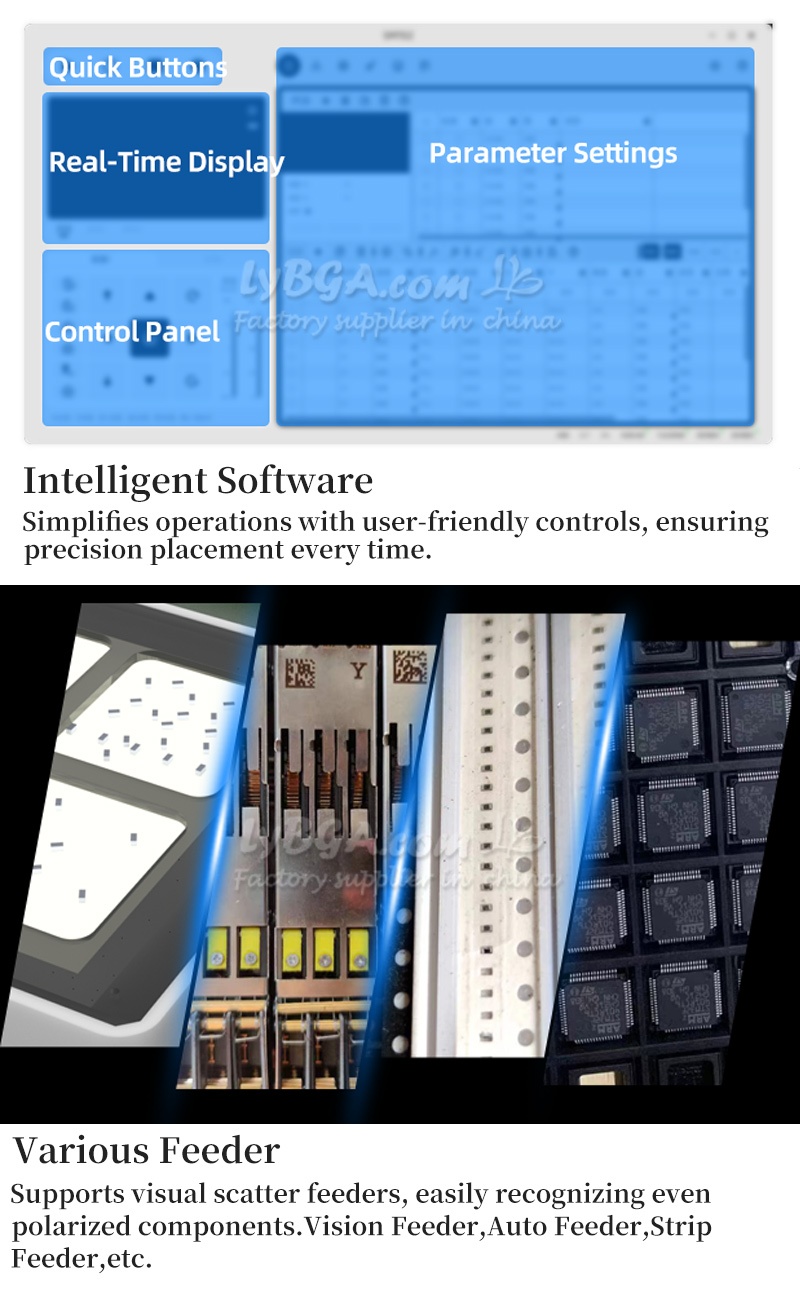

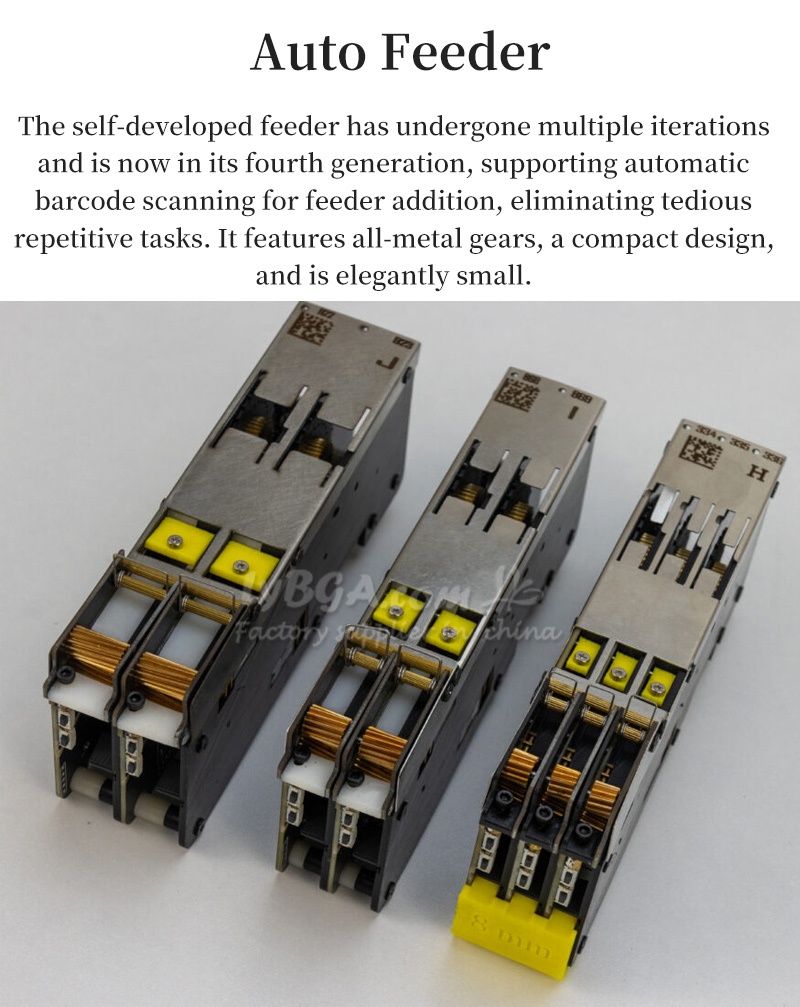

2.4. Versatile Feeding: 1.Vision-assisted loose part feeder, capable of handling polarizedcomponents with ease. 2.Electric feeder with automatic barcode marking, driven by all-metal gears, compact and supports 0402 components. 3.Loose part feeder. 4.Tray feeder.

2.5. Sturdy &Stable: Integrated welded sheet metal frame, stable at high speeds with no vibration. Linear guide ensures smooth and steady motion.

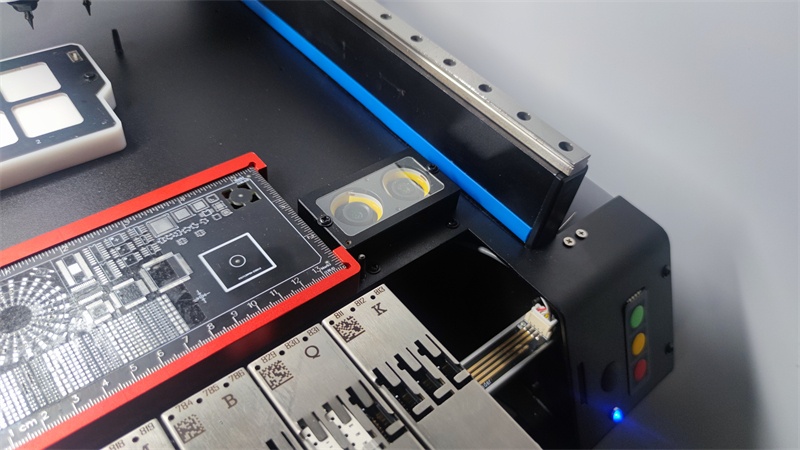

Parameters

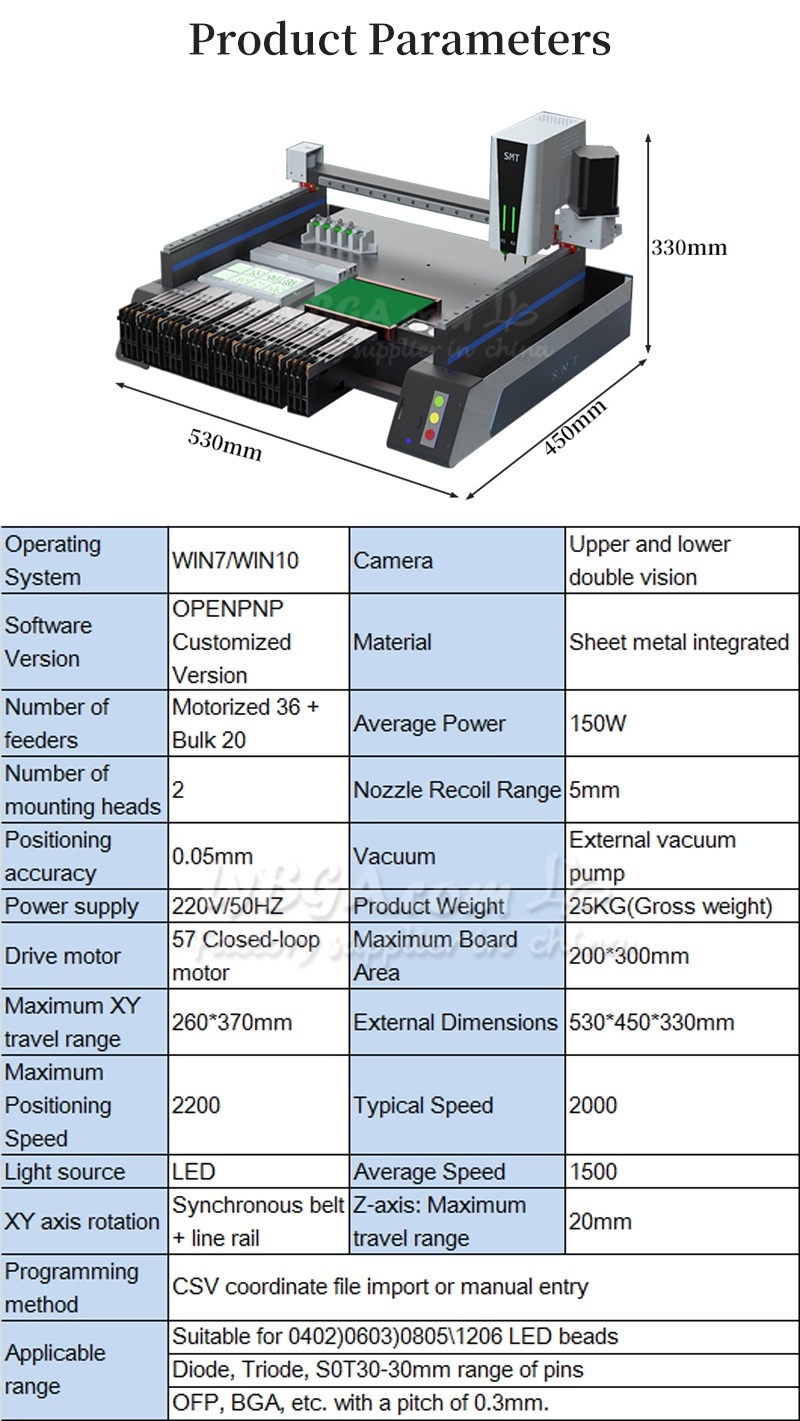

|

Operating System |

WIN7/WIN10 |

Camera |

Upper and lower double vision |

|

Software Version |

OPENPNP Customized Version |

Material |

Sheet metal integrated |

|

Number of feeders |

Motorized 36 + Bulk 20 |

Average Power |

150W |

|

Number of mounting heads |

2 |

Nozzle Recoil Range |

5mm |

|

Positioning accuracy |

0.05mm |

Vacuum |

External vacuum pump |

|

Power supply |

220V/50HZ |

Product Weight |

25KG(Gross weight) |

|

Drive motor |

57 Closed-loop motor |

Maximum Board Area |

200*300mm |

|

Maximum XY travel range |

260*370mm |

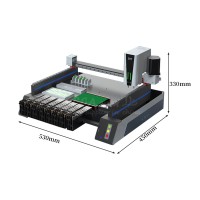

External Dimensions |

530*450*330mm |

|

Maximum Positioning Speed |

2200 |

Typical Speed |

2000 |

|

Light source |

LED |

Average Speed |

1500 |

|

XY axis rotation |

Synchronous belt + line rail |

Z-axis: Maximum travel range |

20mm |

|

Programming method |

CSV coordinate file import or manual entry |

||

|

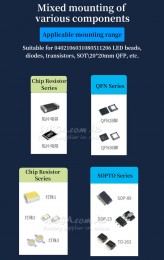

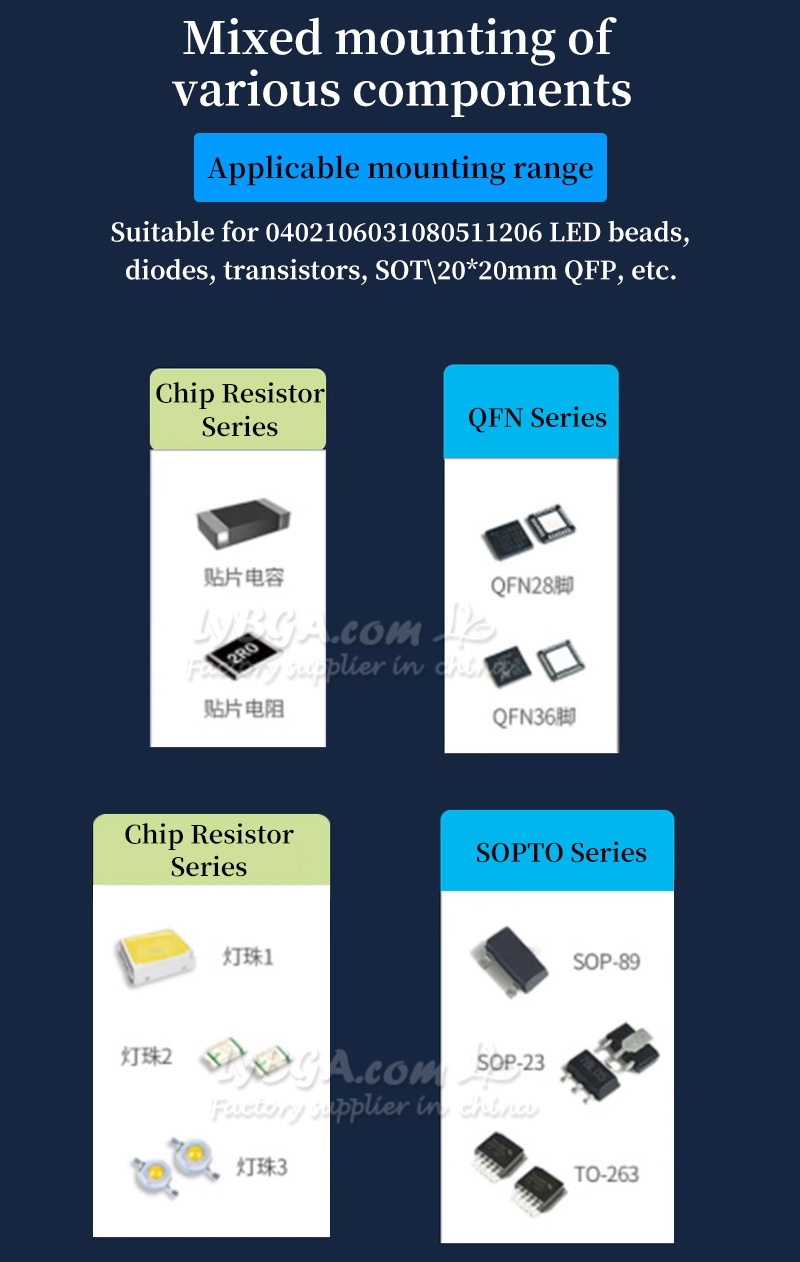

Applicable range |

Suitable for 0402)0603)0805\1206 LED beads |

||

|

Diode, Triode, S0T30-30mm range of pins |

|||

|

OFP, BGA, etc. with a pitch of 0.3mm. |

|||

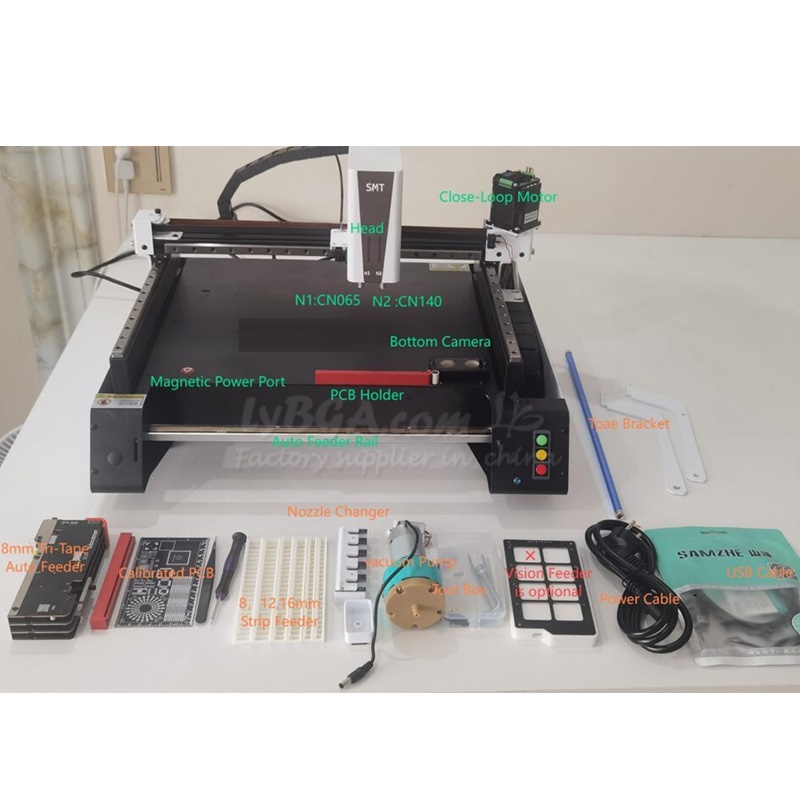

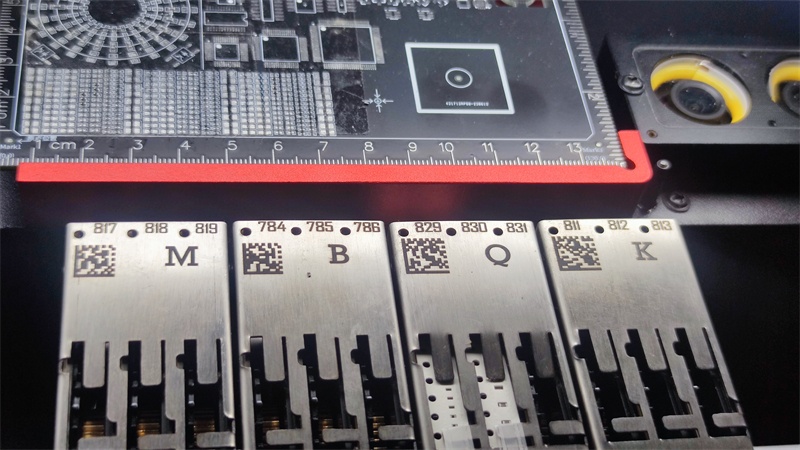

Standard Kit Packing List:

| Sort | Name | Quantity | Mark |

| Machine | LY SMT-K1/K1-PRO | 1 | High-speed dual placement heads, Triple Vision, automatic head change |

| Nozzle | CN065 | 1 | 0603,0805 |

| Nozzle | CN140 | 1 | 1206,Sop8 |

| Feeder | Strip Feeder | 3 | 8mm、12mm、16mm one of each |

| Elec feeder | 8mm Tri-tape Auto Feeder | 1 | Supports 0402 to Sop16, positioning accuracy 0.01mm |

| Others | Nozzle Change Holder | 1 | 5 workstations, providing 4 nozzle replacements |

| Calibrate PCB | 1 | Calibration Position | |

| Vacuum Pump | 1 | Provides vacuum power to the nozzle |

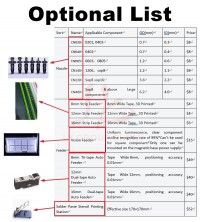

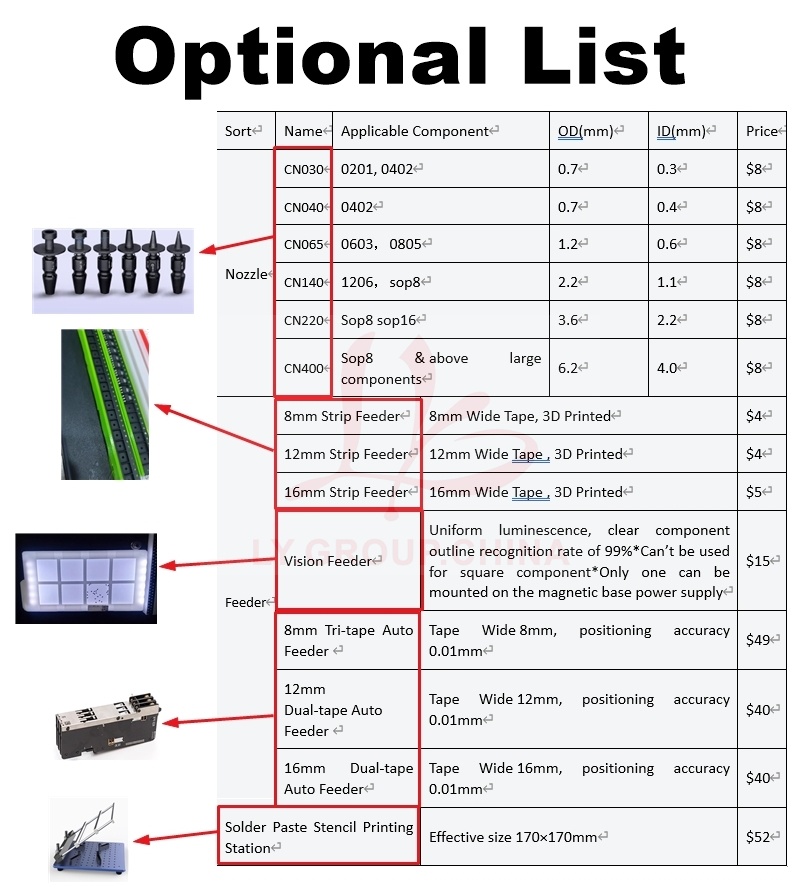

Optional Accessories:

(RE: If need to buy optional accessories pls contact with sales to change total or pay extra.

Machine max support 12 electric feeders.)

| Sort | Name | Applicable Component | OD(mm) | ID(mm) | Price | |

| Nozzle | CN030 | 0201, 0402 | 0.7 | 0.3 | $8 | |

| CN040 | 0402 | 0.7 | 0.4 | $8 | ||

| CN065 | 0603,0805 | 1.2 | 0.6 | $8 | ||

| CN140 | 1206,sop8 | 2.2 | 1.1 | $8 | ||

| CN220 | Sop8 sop16 | 3.6 | 2.2 | $8 | ||

| CN400 | Sop8 & above large components | 6.2 | 4.0 | $8 | ||

| Feeder | 8mm Strip Feeder | 8mm Wide Tape, 3D Printed | $4 | |||

| 12mm Strip Feeder | 12mm Wide Tape , 3D Printed | $4 | ||||

| 16mm Strip Feeder | 16mm Wide Tape , 3D Printed | $5 | ||||

| Vision Feeder | Uniform luminescence, clear component outline recognition rate of 99%*Can’t be used for square component*Only one can be mounted on the magnetic base power supply | $15 | ||||

| 8mm Tri-tape Auto Electric Feeder | Tape Wide 8mm, positioning accuracy 0.01mm | $49 | ||||

| 12mm Dual-tape Auto Electric Feeder | Tape Wide 12mm, positioning accuracy 0.01mm | $40 | ||||

| 16mm Dual-tape Auto Electric Feeder | Tape Wide 16mm, positioning accuracy 0.01mm | $40 | ||||

| Solder Paste Stencil Printing Station | Effective size 170×170mm | $52 | ||||

All-metal one- piece welded frame

More reasonable design and stable body

No vibration at high speed

Easy integration

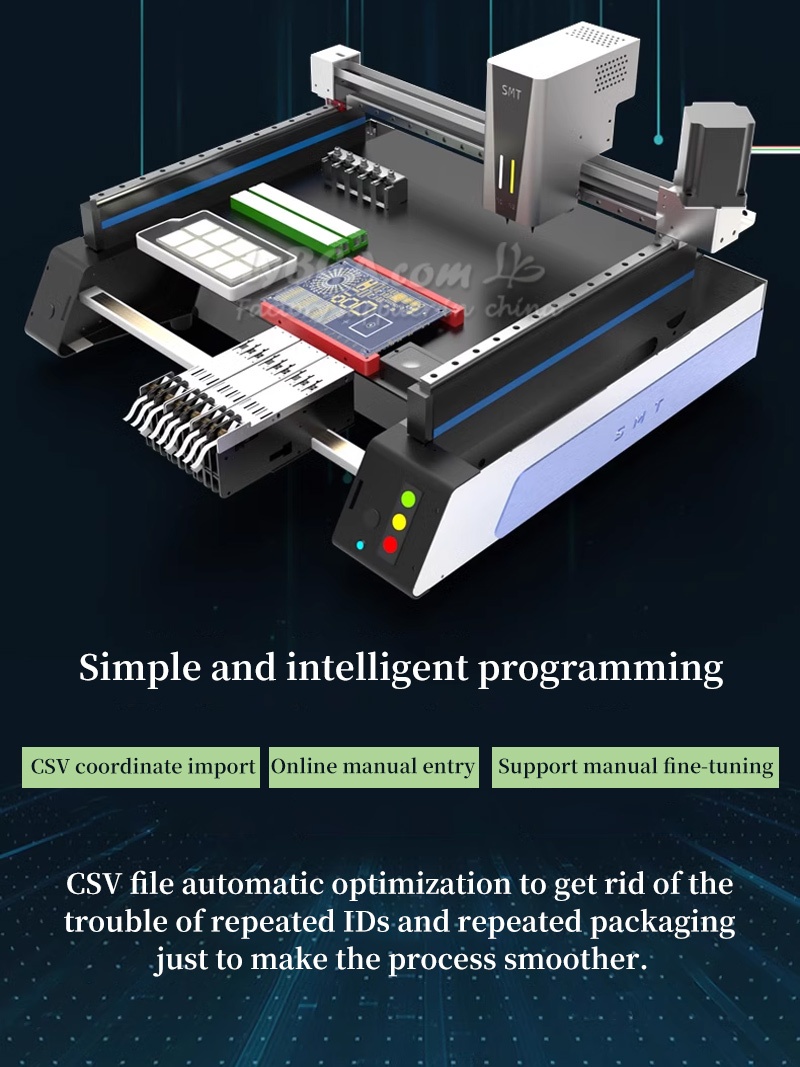

Simple and intelligent programming

- CSV coordinate import

- online manual entry

- Support manual fine tuning

CSV file automatic optimization to get rid of the trouble of repeated IDs and repeated packaging just to make the process smoother.

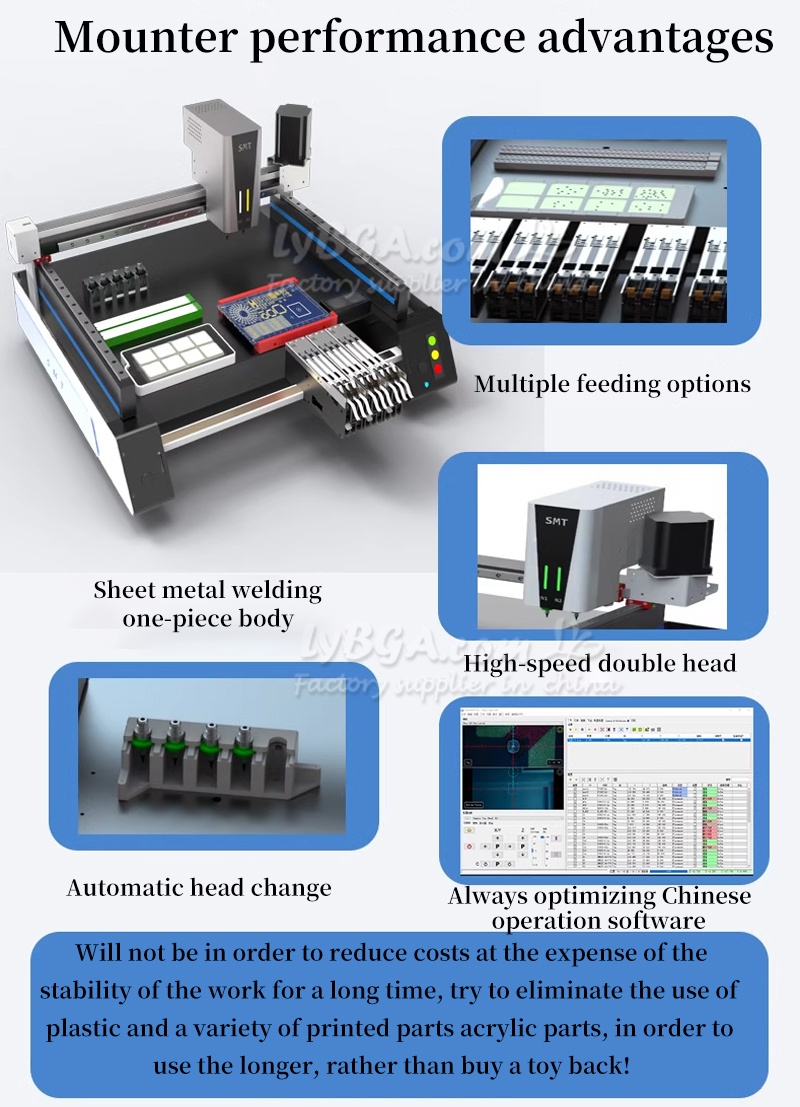

Mounter performance advantages

Multiple feeding options

Sheet metal welding one-piece body

High- speed double head

Automatic head change

Auto Feeder

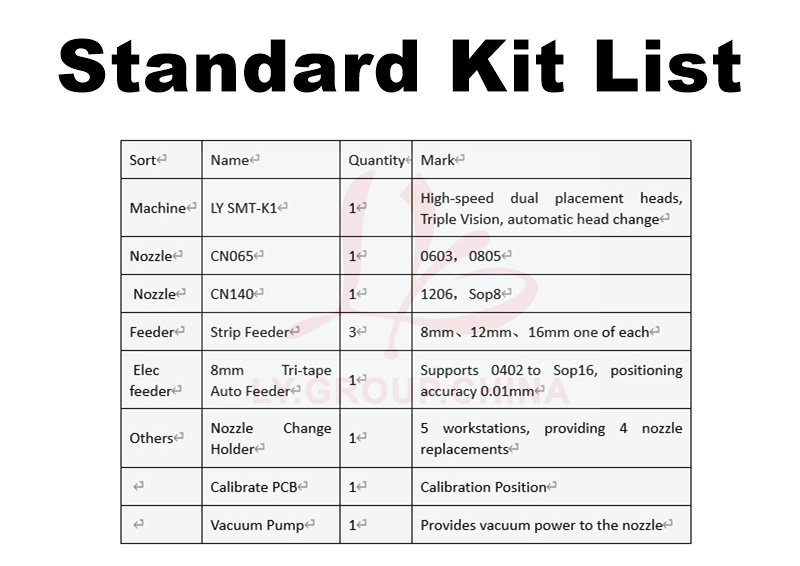

The self-developed feeder has undergone multiple iterations and is now in its fourth generation, supporting automatic barcode scanning for feeder addition, eliminating tedious repetitive tasks. It features all-metal gears, a compact design, and is elegantly small.

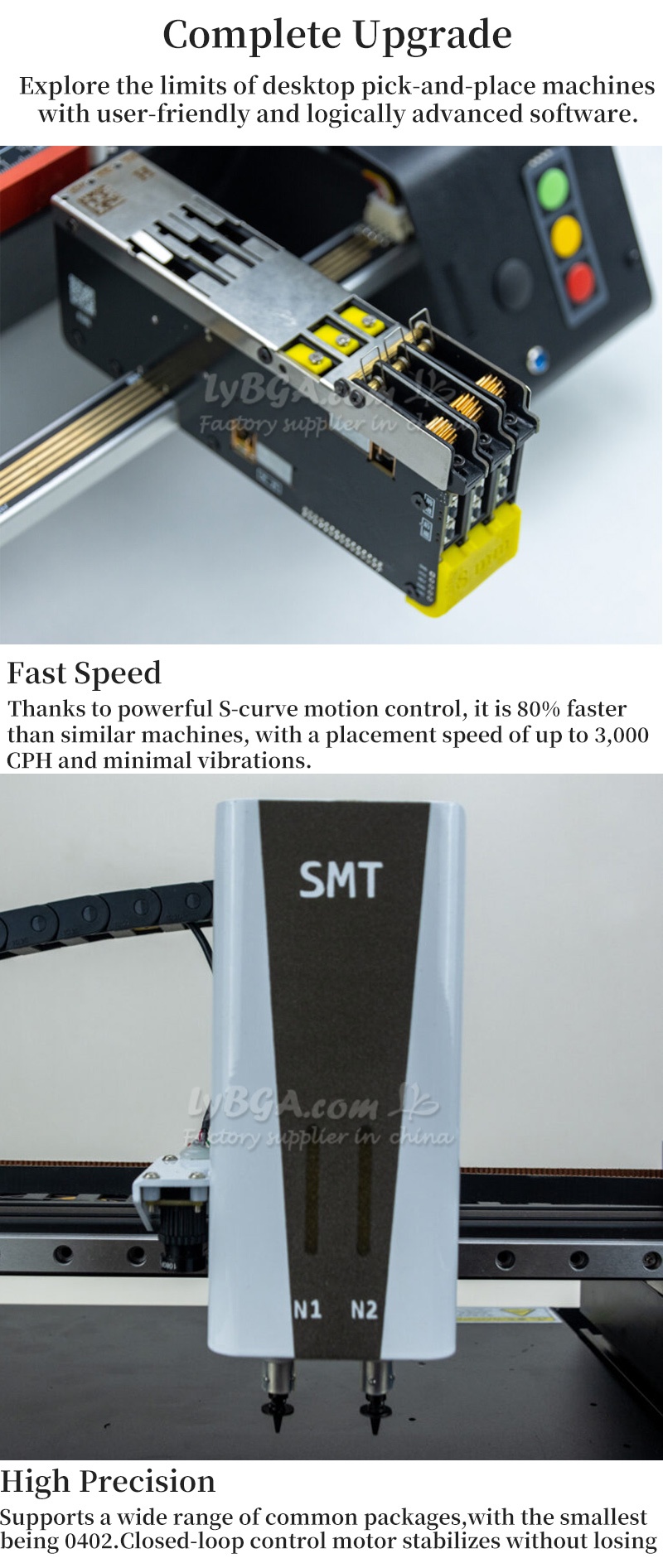

Complete Upgrade

- 1. Fast Speed

Thanks to powerful S-curve motion control, it is 80% faster than similar machines, with a placement speed of up to 3,000 CPH and minimal vibrations.

- 2. High Precision

Supports a wide range of common packages, with the smallest being 0402.Closed-loop control motor stabilizes without losing

- 3. Intelligent Software

Simplifies operations with user-friendly controls, ensuring precision placement every time

- 4. Various Feeder

Supports visual scatter feeders, easily recognizing even polarized components, Vision Feeder, Auto Feeder, Strip Feeder, etc

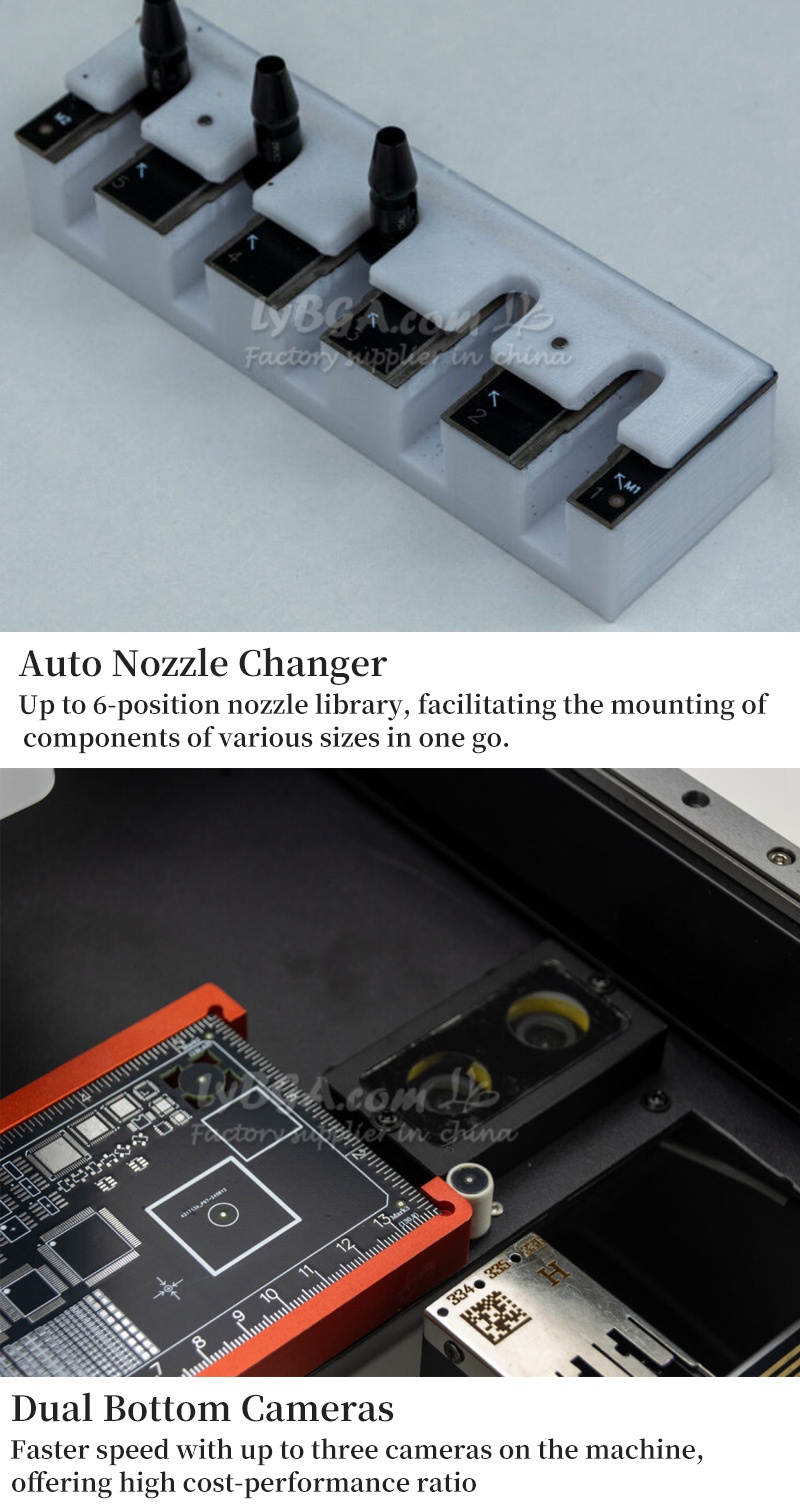

- 5. Auto Nozzle Changer

Up to 6- position nozzle library, facilitating the mounting of components of various sizes in one go.

- 6. Dual Bottom Cameras

Faster speed with up to three cameras on the machine, offering high cost-performance ratio

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!