S&A Dual Circuit Process Air Cooled CWFL 2000 Series Water Cool Chiller Cooling Systems for 2KW Fiber Laser Metal Cutting System

Product Detail

Product Tags

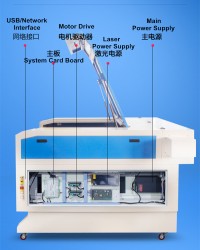

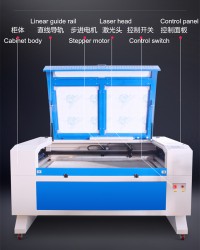

Air cooled water chiller system CWFL-2000 is made specifically to control the temperature of fiber laser metal cutter up to 2KW. It features two channels in one housing, targeting two areas in the fiber laser system – fiber laser and the optics. This dual channel design reduces the chiller footprint to a great extent comparing with the two-single-chiller arrangement. CWFL-2000 industrial temperature control system is designed to operate under indoor condition and can be easily serviced by taking away the side housings. It comes equipped with an easy-to-read water level check and easy-fill port, making water adding quite convenient.

Product Parameters

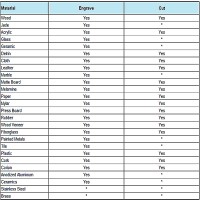

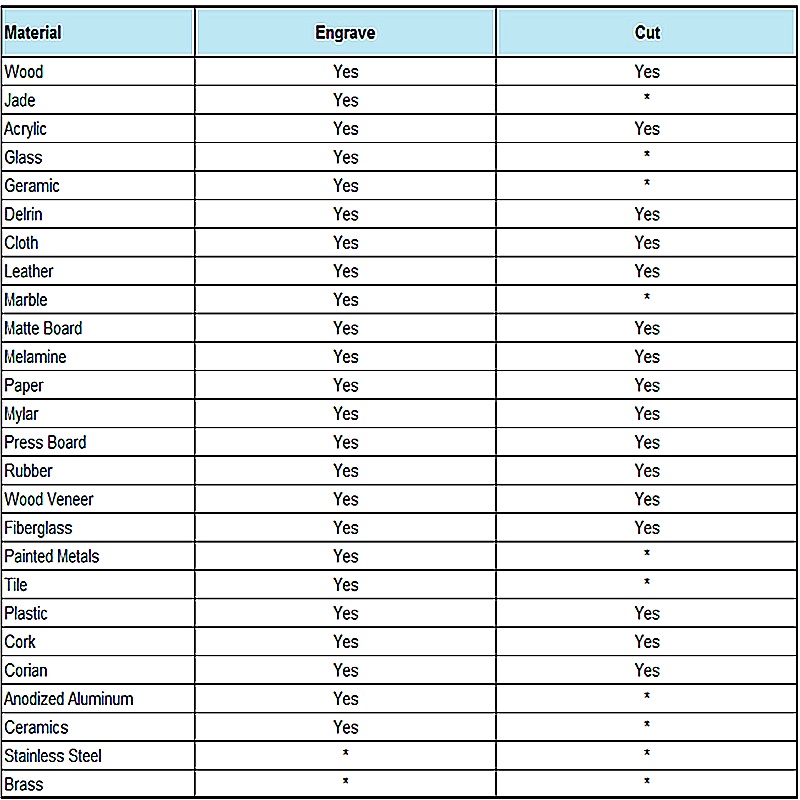

|

Model |

CWFL-2000ANP |

CWFL-2000BNP |

|

Voltage |

AC 1P 220-240V |

AC 1P 220-240V |

|

Frequency |

50Hz |

60Hz |

|

Current |

3.4~17.8A |

3.9~17.3A |

|

Machine power |

3.03 kW |

3.38 kW |

|

Electric assisted power |

600W+600W |

|

|

Precision |

±0.5°C |

|

|

Reducer |

Capillary |

|

|

Pump power |

0.55kW |

0.75kW |

|

Tank capacity |

14L |

|

|

Inlet and outlet |

Rp1/2″+Rp1/2″ |

|

|

Lift |

44M |

53M |

|

Rated flow |

2L/min+>15L/min |

|

|

N.W. |

77Kgs |

70 Kgs |

|

G.W. |

87Kgs |

82Kgs |

|

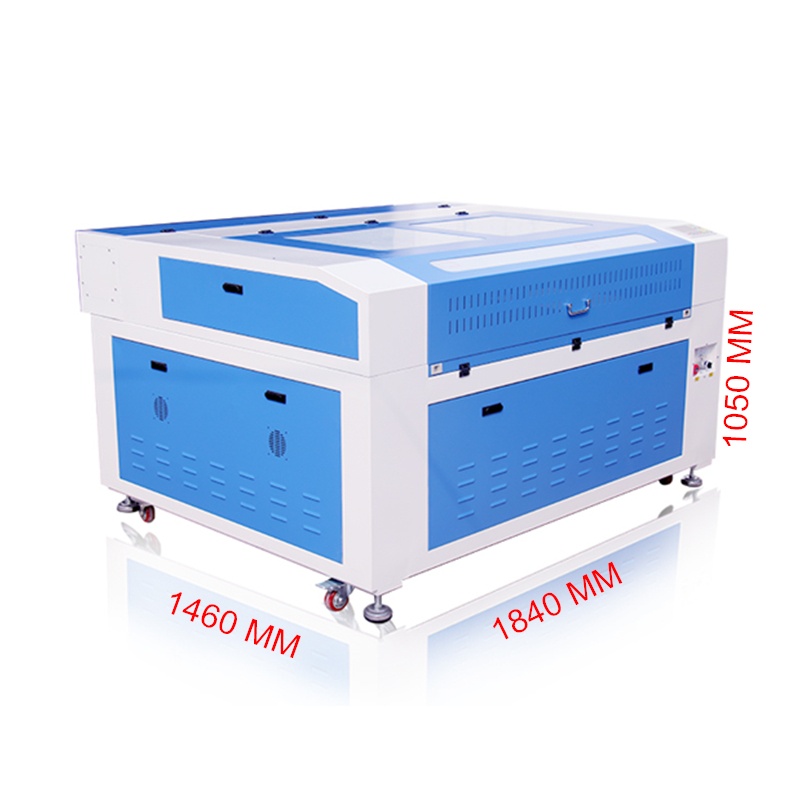

Dimension |

70 X 47 X 89cm (L X W X H) |

|

|

Package dimension |

74 X 61 X 104 cm (LX W X H) |

|

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

Product Features

* Dual cooling circuit

* Active cooling

* Temperature stability: ±0.5°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410a

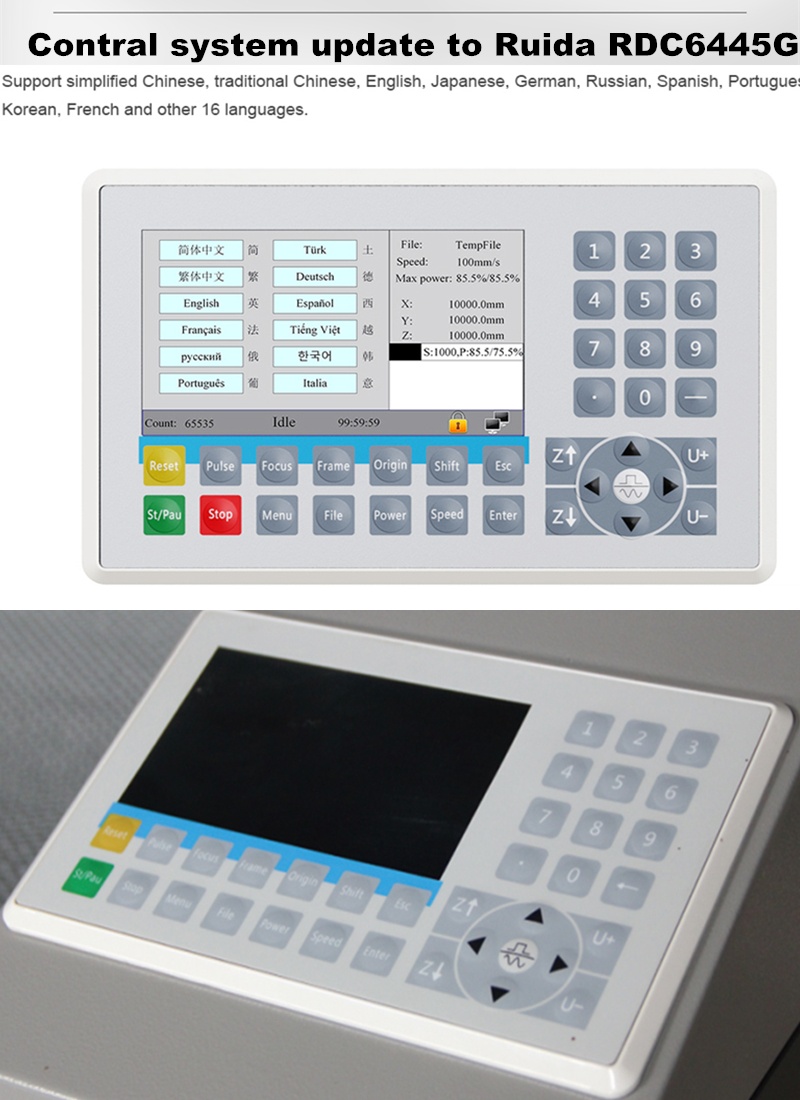

* User-friendly controller interface

* Integrated alarm functions

* Back mounted fill port and visual water level

* Optimized for high performance at low temperatures

* Ready for immediate use

FAQ

Is S&A Chiller a trading company or a manufacturer?

We are professional industrial chiller manufacturer since 2002.

What is the recommended water used in the industrial water chiller?

The ideal water should be deionised water, distilled water or purified water.

How often should I change out the water?

Generally speaking, the water changing frequency is 3 months. It can also depend on the actual working environment of the recirculating water chillers. For example, if the working environment is too inferior, the changing frequency is suggested to be 1 month or shorter.

What is the ideal room temperature for the chiller?

The working environment of the industrial water chiller should be well ventilated and the room temperature should not be higher than 45 degree C.

How to prevent my chiller from freezing?

For users living in high latitude areas especially in winter, they often face the frozen water problem. To prevent the chiller from freezing, they can add an optional heater or add anti-freezer in the chiller.

Thanks for your order!

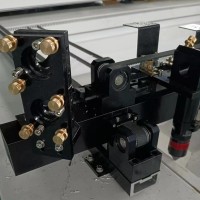

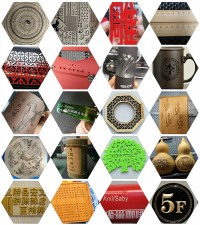

Product Pictures

Questions, issues or concerns? I'd love to help you!