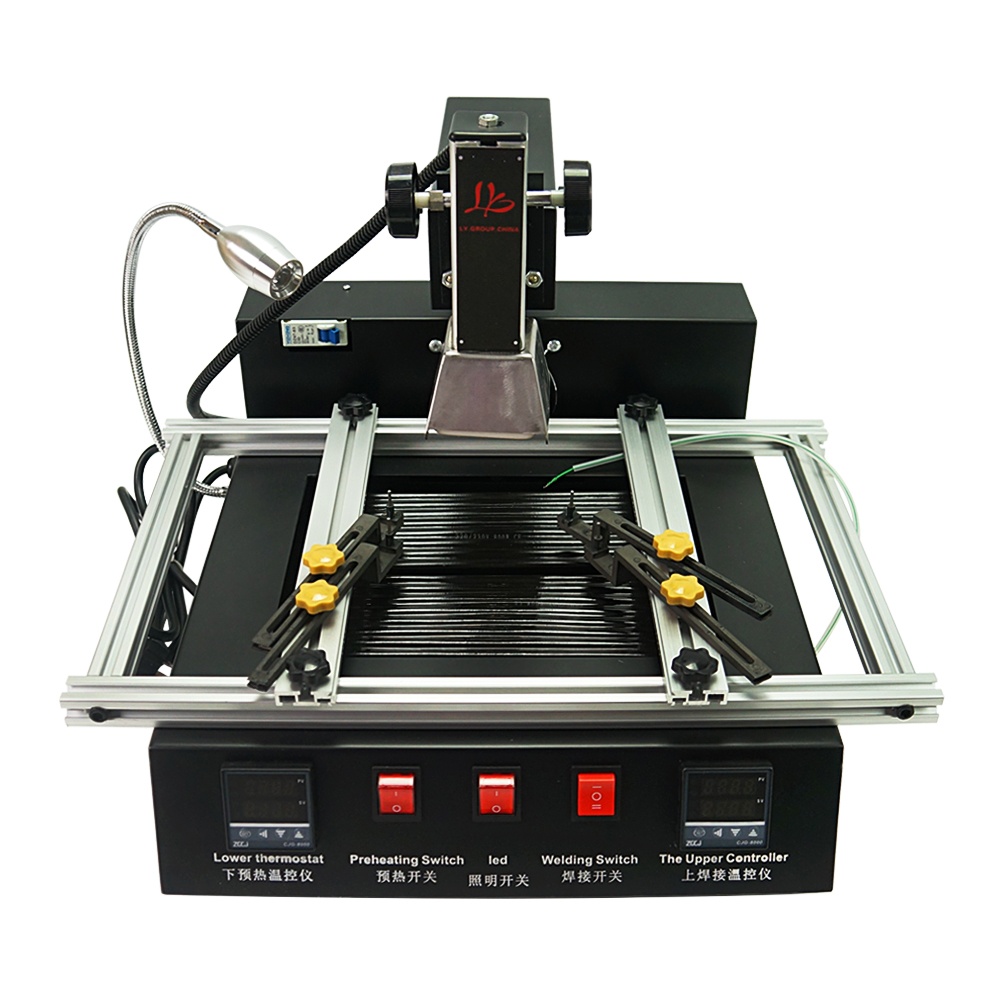

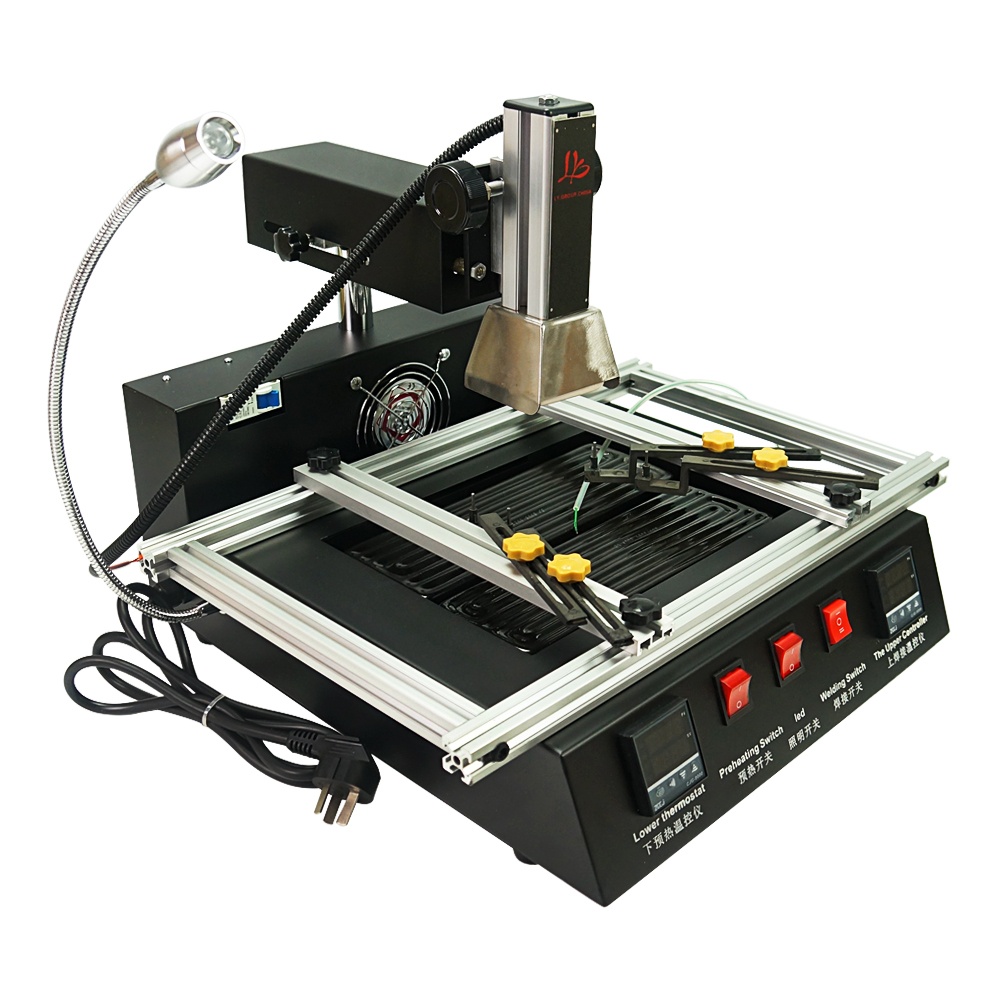

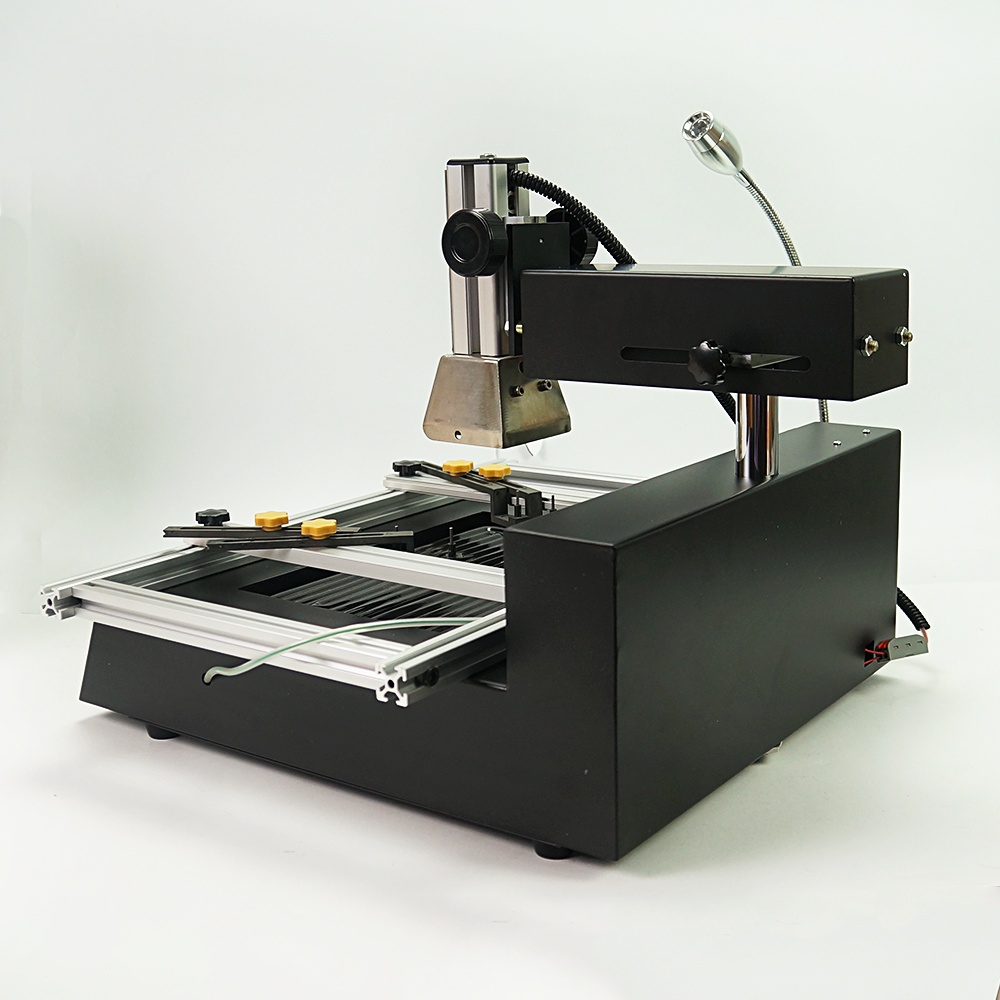

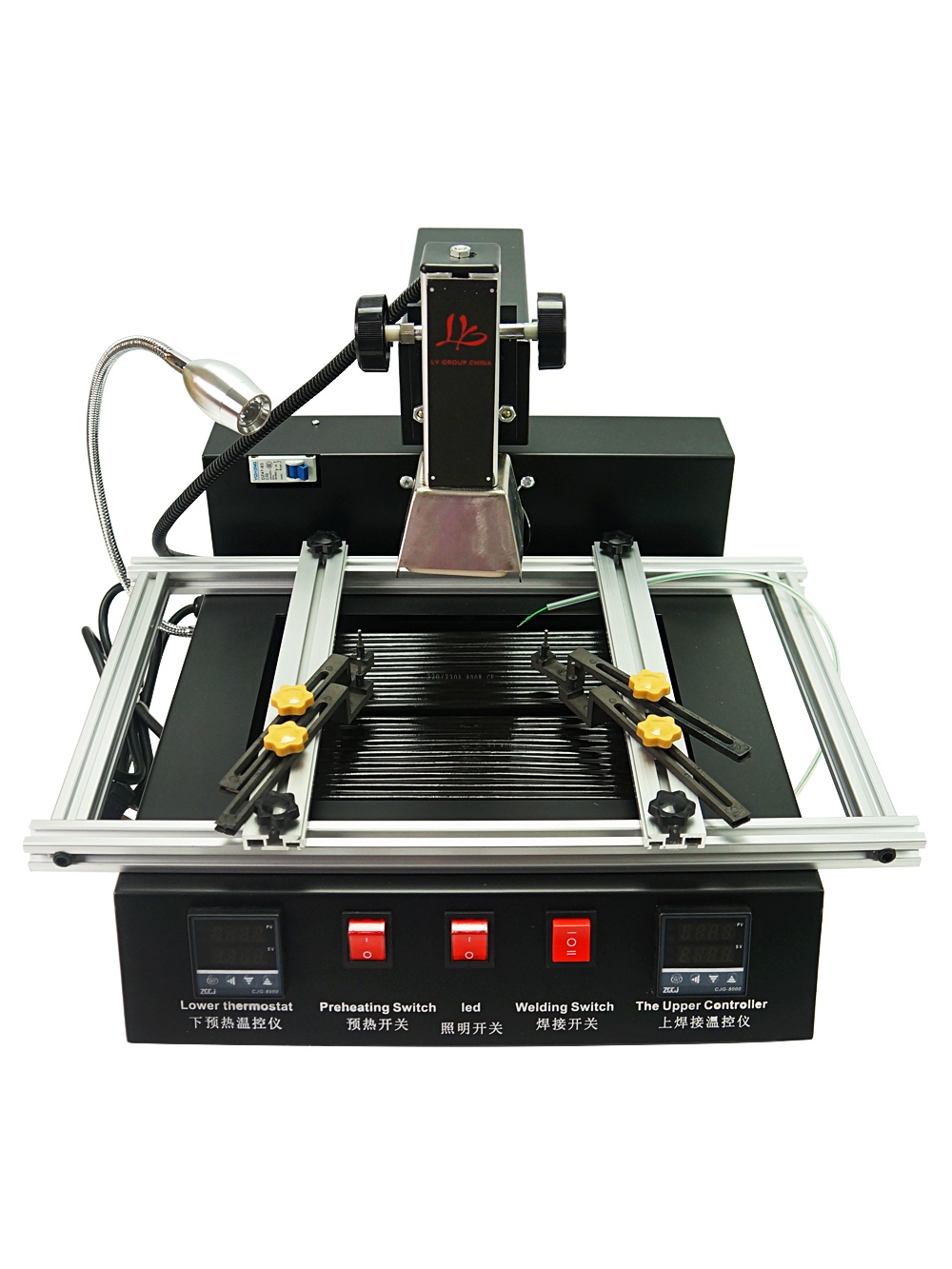

The most economic upgraded IR bga model LY M770 M770R BGA Rework station 220V 2 zones manual operation 1900W

Product Detail

Product Tags

The most economic upgraded IR bga model LY M770 M770R BGA Rework station 220V 2 zones manual operation 1900W

(RE:M770R with more 1 kit direct heat reballing jig than normal M770.)

Feature:

This model maybe the cheapest 2 zones infrared bga rework station,if you are newbie ,or have limited budget ,you can consider of this model.

|

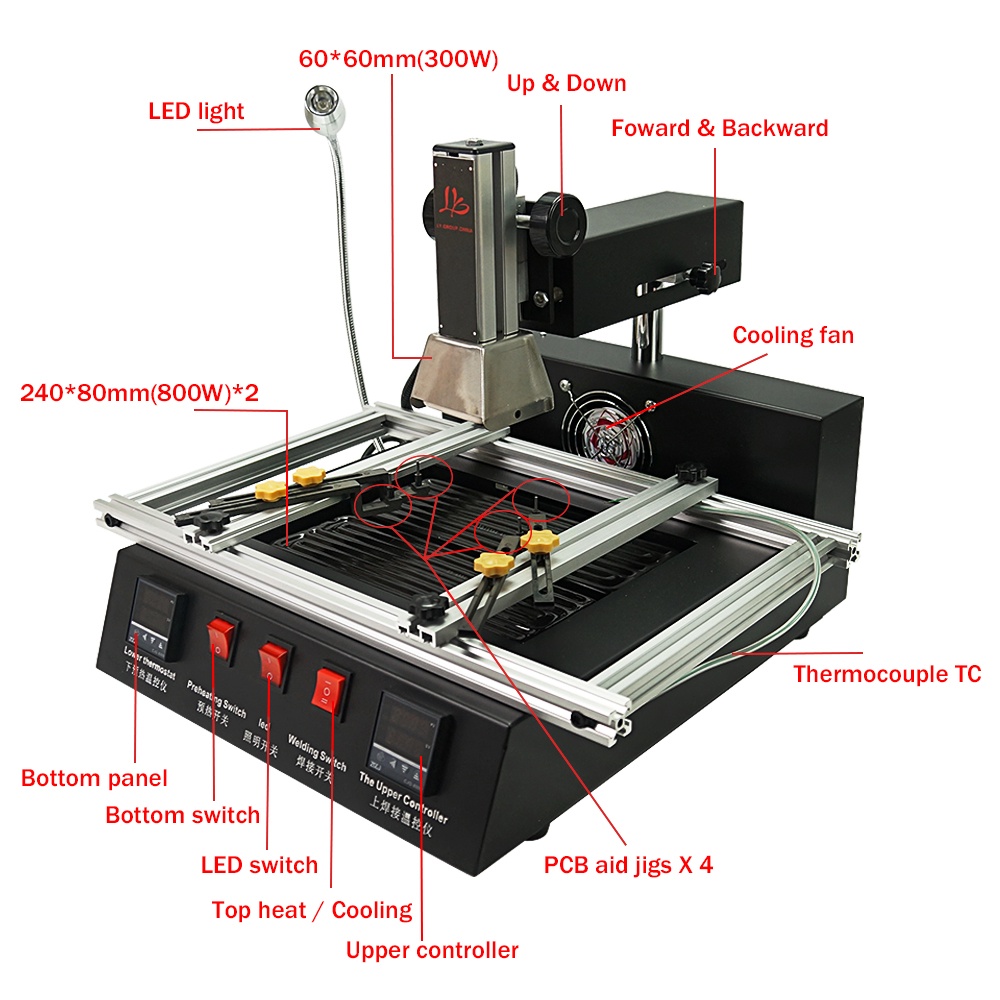

Specs: |

|

|

Heating Zones |

2 zones |

|

Top Size |

60*60mm |

|

Top Power |

300W |

|

Bottom size |

240*80mm*2 pcs |

|

Bottom Power |

1600W |

|

Machine size |

450*450*460mm |

|

Power |

220V,50/60HZ |

|

Gross weight |

20KG |

|

Operation |

Manual |

|

Software |

Not support |

The parameters and performance indicators:

1. The rework station suitable for notebook computer motherboard, desktop computer motherboards, computer and server motherboard, motherboard, motherboard, large game machines, communications equipment, motherboards, LCD TV motherboard, motherboard, print circuit board repair.

2. The BGA chips rework station can be very effective in replacing the stack memory, the replacement of the BGA chip, memory below will not take slurry.

3. The rework station can be very successful in solving BGA chip heated foaming problem. (constant temperature 100 degrees available preheating.

4. Preheat to repair the motherboard 1-2 minutes. Then heating.

5. The rework station can replace CPU notebook memory slot to facilitate the.

6. BGA chip to be an easy job to replace glue sealing, sealing glue chip to the rubber (hot-air or in addition to adhesive glue).

7. The replacement of the BGA chip, the circuit board can not turn yellow.

8. The rework station using infrared preheating and infrared heating, lower preheating station, PCB board for preheating, ensure that the PCB plate can not be deformed, preheating station area of 245*180. Can fully meet the desktop and notebook computer repair.

9. Rational design of support structure, the replacement of the BGA chip is not deformation, very convenient and practical.

10. The rework station can do circuit board drying and circuit board shaping.

The rework station welding success rate is almost 99%, if can’t achieve this goal, probably because of the new machine, please try it a few times.

Rework station operations guide:

1, the motherboard in the preheating stage, the board fixed bracket.

2, the welding joint alignment chip from the chip 10MM, welding head, with a chip on the temperature probe.

3, open the preheat switch, to lead the chip preheating temperature set at 280 degrees, to preheat the motherboard, the motherboard preheating time needed for more than ten minutes, then open the welding joint, the welding of the chip, the upper temperature controller temperature set to 220 degrees (three temperature zones lead-free please refer to the following temperature open the settings) welding welding switch as long as 150 seconds to complete chip.

4, close the heating switch, a lower preheating switch, remove the welding head to the motherboard, after cooling, can move the motherboard.

5, open the cross-flow fan, heat dissipation on the motherboard, about heat about 2 minutes can remove the motherboard, power off.

Have the relevant knowledge and welding:

How much is the lead solder and lead-free solder melting point respectively?

Lead solder melting point of 183 degrees, lead-free solder melting point of 217 degrees

Cannot determine the board is a lead or lead-free, how to set the temperature?

According to lead to set temperature, heating is completed, use tweezers to gently touch the BGA chip, if the chip can move smoothly, said welding success, if the chip can’t move, said solder may be lead-free, set the temperature for lead-free, heating is completed, the same use tweezers to touch, in order to confirm whether the welding success, also can look at capacitance bridge near, if the two are more lead-free tin solder, tin lead less, the general new machines are almost lead, INTEL chip with FW is a lead, take NH lead-free lead-free than about a lead temperature 20 degrees, VIA chip with a G lead-free, has lead to melting point of 183 degrees, unleaded melting point of 217 degrees, can be distinguished through the spot color, lead solder joints with a shiny, lead a partial white

metal feeling gloss is not good, there is a judgment about the ways of looking at models, the new machine are all lead-free soldering (considered from the environmental point of view, in addition to do) when lead-free bridge suggest you mask slightly more, because of the mobility of lead-free and invasive are poor, not easy to repair.

6. Series chip set up basic are lead-free, judgment can be started from several aspects of solder joints, gloss, lead-free solder paste because of high melting point, during the reflow process oxidation than lead hard, easy to lose their luster, but time lead long gloss will decline. See chip sets, with N or NH as the lead, but I think, Toshiba some previous original board, although the chipset is a lead, but PCB should still lead. Look at the screw holes, lead-free generally not tin, but not absolutely. See the ICT test point, lead is flat, lead-free tend to drum up a little. There are many aspects can be distinguished, this is not the only one.

Solder paste plays what role?

Solder paste can clear the pad surface oxide, enhanced the activity of solder.

Hot air heating and infrared heating what is the difference?

For BGA rework station hot air heating, air flow, the shift may lead to components. The air flow, resulting in hot air can not be directly heated BGA chip and solder ball, otherwise the ball may stick together (part of the direct heating type steel mesh can be used).

In addition to control temperature, but also control the volume, so the BGA rework station hot air heating is often more complex structure, huge volume.

Hot air type BGA rework station need step heating, temperature parameter setting complex, users have to master the 100-200 temperature curve, a different board should have different temperature curve, the selection of a suitable set of from different temperature curve, for beginners may be more difficult.

Hot air type BGA rework station must be connected to the computer, can guarantee higher work efficiency. Hot air rework station on the circuit board position requirements higher, BGA chip to be very accurate alignment of the wind mouth, if the circuit board and BGA chips dislocation, will cause the welding failure.

Infrared heating is a new technology developed in recent years, infrared heating BGA rework station has the advantages of simple structure, accurate temperature control, easy to operate.

There are two reasons for the circuit board deformation:

First, is the preheating area is too small, the circuit board is not uniformly heated;

Secondly, the circuit board placing unreasonable, not smooth, without locking.

How to solve the problem of false?

Can be directly welded. The f

irst to chip into the amount of flux or pine, then heating.

If welding is not successful, will need to take down the redo BGA chip.

How will the pad alignment of BGA chip and the circuit board?

There are corresponding to the BGA chip line on the circuit board, the BGA chip and the frame alignment can be placed.

For the ball more than 0.65mm spacing of BGA chip, the direct use of manual alignment can be, without the need for optical equipment with the help of professional. Such as notebook computer board, desktop computer motherboards, computer boards, server board, large and medium-sized game board

For BGA chip underfill encapsulant below 0.5mm, often need to resort to the accurate alignment of optical devices. For example, LED lamp.

Notebook computer pad spacing have how old?

Solder ball notebook computer is how much?

Pad spacing notebook computer has three kinds: 1.27mm 1mm 0.8mm

Solder ball notebook computer application has three kinds: 0.76mm 0.6mm 0.5mm

The spacing of 1.27mm chip using 0.76mm solder ball

The spacing of 1mm chip using 0.6mm solder ball

The spacing of 0.8mm chip using 0.5mm solder ball

X machine can detect the BGA chip is welded with?

X machine can accurately determine the fault solder adhesion.

For the problem of weld, X machine can not accurately judge.

For the chip overheating damage problem, X machine can not judge.

X machine in the price between 20-100 million.

To accurately determine whether the success of the most accurate way of welding is a functional test. Also is the power-on test circuit board can work normally.

What is the infrared heating?

Infrared ray is a ray of sun many invisible light, is located outside the red light, so called infrared. In the spectrum of wavelengths from a period of 0.76 to 400 microns called infrared, infrared thermal effect.

Infrared heating dazzling?

Infrared is not visible light, infrared not glare. Glare is often the incandescent lamp.

The use of small electronic products mobile phone, digital camera, BGA chip size is very small, pads on the chip is small, spacing pad is small, easy to solder tin slurry forming to the BGA chip, more appropriate.

BGA chip used in computer, game machine, computer, LCD TV and other large circuit board often size is large, the chip pad, pad spacing is very large, in order to ensure the forming the ball size uniform, with the ball better.

Temperature setting method· temperature control table has two rows of digital tube, the top line PV is the display of the measured temperature, the following line SV is the display of set temperature.

· digital tube left with four indicating lamps, AL

jiangmaolin (18:55:44):

M1 alarm, OUT alarm is heating, AKM2, AT correction.

Through the digital tube below a row of four buttons. From left to right: set key, the left key, down the direction key, key upward direction.

· set the temperature of the following methods:

Hold down the SET key to more than one second (no more than 2 seconds), the top line of digital tube display SO, and a line of digital tube display settings, and set the value of one flickers.

Through the press direction key to digit switching digital tube.

According to the above key or keys to downward, can increase or decrease the value.

After the completion of the set, press SFT second to return.

· Hessian rework station temperature sensor has direct contact with the circuit board, circuit board chip sensor detects the temperature.

· part of electrolytic capacitor plastic socket cannot resist high temperature, to prevent the high temperature bake bad, please adhered on the surface of the insulation sheet.

· paste coated evenly, not painted too much, too much solder paste may cause weld.

· use knife head iron performance good scraping residual solder pads, be careful of tin, the provision of free to rub off the pad on the PCB board, pad most would be the normal work of a circuit board.

· circuit board welding to cold to room temperature before power-on test.

· PCB in addition to tin, please clean, pad to light, otherwise may not stick solder, lead solder.

The sensitivity of · the rework station the configuration of the sensor is very high, the air flow will lead to a digital display of temperature jump, jump in the rate is a normal phenomenon in +-5 degree. Reduce the air flow can effectively reduce the digital display of the jump value.

· solder melting, BGA chip will be in a floating state, can use tweezers touch detection, temperature did not accurately regulator before test, application of vacuum suction pen, when only a small amount of pad can not fully melting, vacuum suction pen may lead to pad off.

· board or BGA chip if too wet, want to dry before they can use, damp circuit board or chip after heating may burst, may hear a popping sound work process.

· modify the temperature parameter, the bad old motherboard on rework station, heating one or more complete workflow, use tweezers to gently touch the BGA chip, if the chip can move smoothly, show that the fully molten solder. Work process before the end of 20 seconds is appropriate if the melting solder, solder melting before too long, recommended temperature appropriate reduction, in order to prevent edge weld or high temperature damage the chip solder ahead of schedule, if too short, recommended temperature adjustable high, to prevent air welding.

The BGA chip is stuck insulating tape, may affect the heat transfer, resulting in the process after the end, solder still can not melting, with longer heating time, can solve this problem.

Warranty regulations and precautions:

· from the date of purchase. This product Neibao returned a week, one year free warranty, one year after the repair only charge the cost of materials.

· if the user did not inform our circumstances to cause for disassembly and circuit is modified, not within the scope of the warranty.

· if user errors such as reasons not to return.

· the equipment is not waterproof, no water or wet.

· the machine working voltage is 220V, please do not use non 220V power supply mode.

· the use of this equipment, to ensure its effective ground, to prevent leakage.

· the equipment work, preheating and heating head in a high temperature state, this site can not contact with the skin, to prevent burns.

· do not close to the welding head temperature control instrument, otherwise it will burn Wen Kongyi

Disclaimer:

The master of this machine, please users to wear the old circuit board exercise machine operation process. Otherwise, the machine’s operation as improper use, the resulting loss alone by the user, because the work environment is different, set the parameters of heating temperature will change a little, ask users to regularly adjust the temperature parameters, results in debug prevail, so as to maximize the efficiency.

Note: the above is only for reference, because the specific use, and the motherboard, chip. And the environment, have a relationship, so the flexible key, if can not solve the problem please contact us, we have professional engineers to provide guidance.

metal feeling gloss is not good, there is a judgment about the ways of looking at models, the new machine are all lead-free soldering (considered from the environmental point of view, in addition to do) when lead-free bridge suggest you mask slightly more, because of the mobility of lead-free and invasive are poor, not easy to repair.

6. Series chip set up basic are lead-free, judgment can be started from several aspects of solder joints, gloss, lead-free solder paste because of high melting point, during the reflow process oxidation than lead hard, easy to lose their luster, but time lead long gloss will decline. See chip sets, with N or NH as the lead, but I think, Toshiba some previous original board, although the chipset is a lead, but PCB should still lead. Look at the screw holes, lead-free generally not tin, but not absolutely. See the ICT test point, lead is flat, lead-free tend to drum up a little. There are many aspects can be distinguished, this is not the only one.

Solder paste plays what role?

Solder paste can clear the pad surface oxide, enhanced the activity of solder.

Specifications:

01. Applicable to laptop motherboard, desktop motherboard, XBOX-360, server motherboard, digital products etc..

02. Two heating zones, independant heating, upper heating 300W, bottom preheating 1600W

03. Maximum heating temperature : 500 degree

04. Used high accurate Intelligent temperature controller, make more accurate temperature controlling

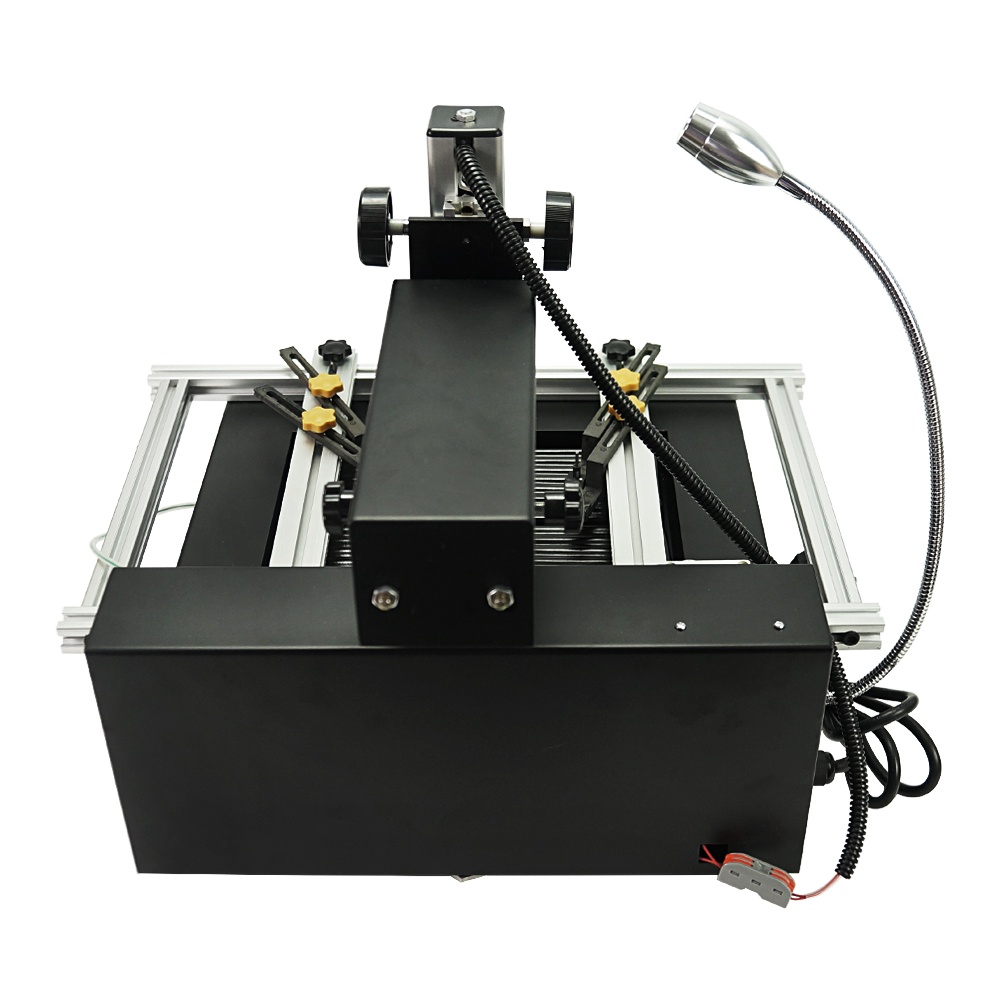

05. Movable heater, easy and convinient to use

06. Infrared heating panel, independant controlling heating

07. Brilliant-designed Universal circuit board structural support, weld zone part non-support, none sink

08. Bottom preheater, used to preheat PCB, to make sure it non-deformation, maximum heating area 450 * 500mm

09. No limit for PCB thickness during desoldering

10. No limit for BGA chips size during desoldering, max size for 775CPU, min size for CCD grain

11. Dimension: L450 * W450 * H460mm

12. Power supply: 220V 5060Hz

13. Effective power: 1900W

14. Weight: 20kg

15. Factory bulk welding success rate up to 98%, machine warranty for 1 year

RE:Not support communication by software with Com.

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!