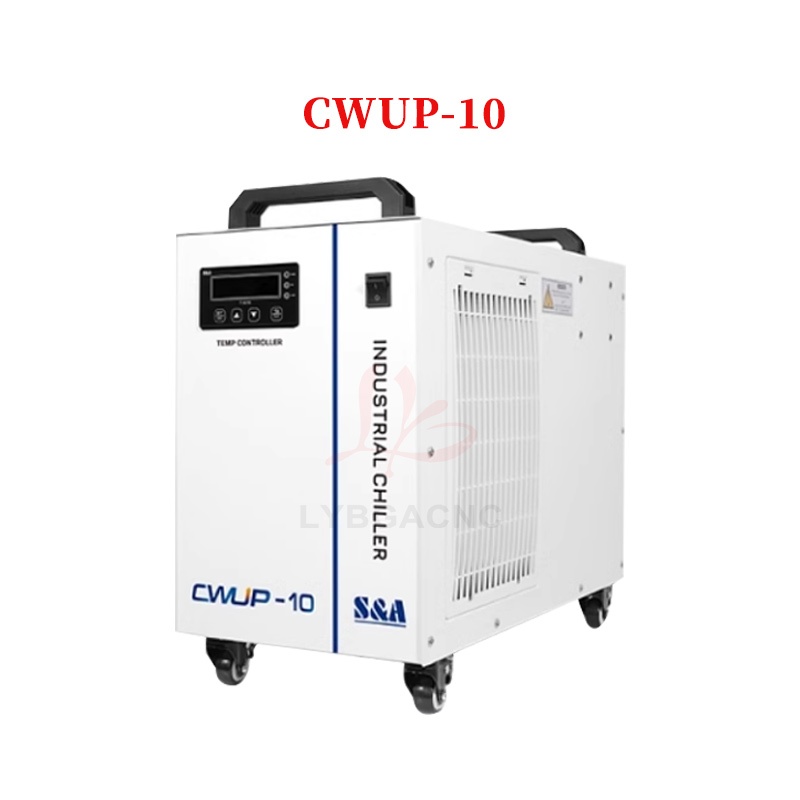

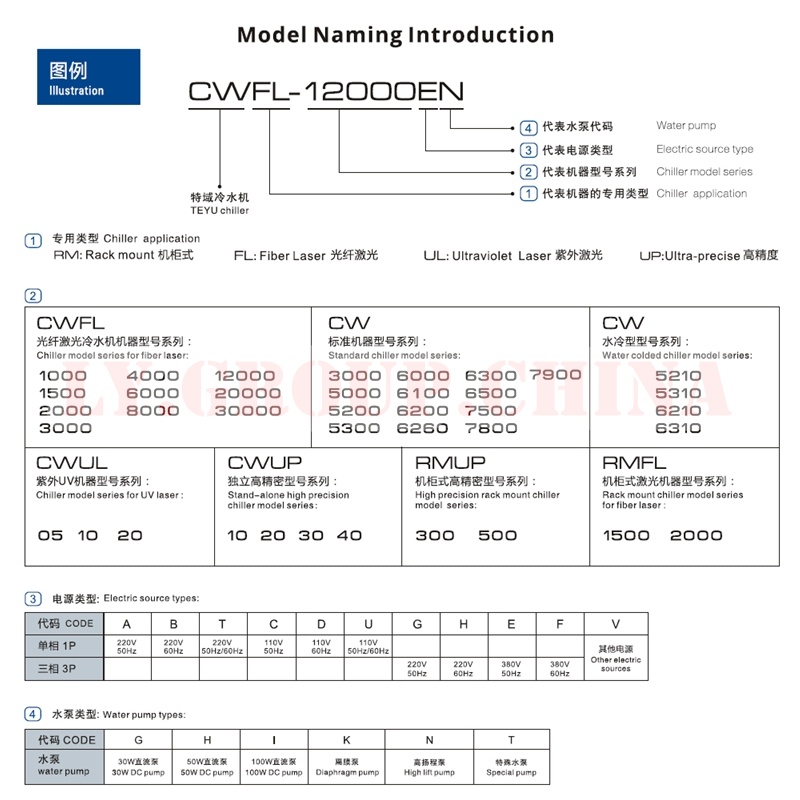

S&A CWUP-10 20 Small Industrial Chiller for Ultrafast Laser UV Laser Marking Machine with ±0.1°C High Control Precision

Product Detail

Product Tags

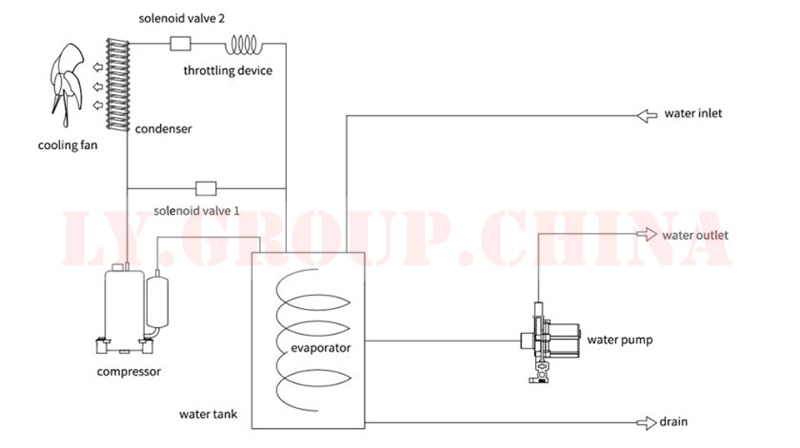

CWUP-10 is designed specifically for ultrafast laser and UV laser. Small as it is, its temperature control ability doesn’t compromise. This laser water chiller delivers superior temperature control of ±0.1°C with PID control technology. It is designed with a compressor refrigeration circuit with properly designed pipeline arrangement, which avoids the generation of bubble to reduce the impact to the lasers. What makes CWUP-10 industrial chiller even unique is that it incorporates the RS485 communication function, providing higher level of communication between the chiller and the laser system.

CWUP-20 is an active cooling portable water chiller that optimizes the operation of your ultrafast laser and UV laser system. This small water chiller delivers a particularly high degree of temperature stability of ±0.1°C. Water temperature is PID controlled and the water chiller is designed with multiple built-in alarm functions. Another highlight is that CWUP-20 chiller supports RS485 communication with the laser system. Easy-fill port is mounted on top while 4 caster wheels are easy for mobility.

Product Parameters

|

Model |

CWUP-10 / CWUP-20 |

|

Voltage |

AC 1P 220-240V |

|

Frequency |

50Hz |

|

Current |

0.8~3.5A / 0.8~5.6A |

|

Machine power |

0.81kW /0.96 kW |

|

Compressor power |

0.32KW / 0.59 kW |

|

0.43HP / 0.8HP |

|

|

Nominal cooling capacity |

3036Btu/h / 5783 Btu/h |

|

0.89kW / 1.7 kW |

|

|

765Kcal/h / 1457Kcal/h |

|

|

Refrigerant |

R-134a / R-410a |

|

Refrigerant charge |

300g / 650g |

|

Precision |

±0.1℃ |

|

Reducer |

Capillary |

|

Pump power |

0.1kW |

|

Tank capacity |

6L |

|

Inlet and outlet |

Rp1/2″ |

|

Max. pump lift |

25M |

|

Max. pump flow |

16L/min |

|

N.W |

24.8Kgs / 26Kgs |

|

G.W |

27.4Kgs / 31Kgs |

|

Dimension |

58X29X47cm (L X W X H) |

|

Package dimension |

65X39X62cm (L X W X H) |

FAQ

Is S&A Chiller a trading company or a manufacturer?

We are professional industrial chiller manufacturer since 2002.

What is the recommended water used in the industrial water chiller?

The ideal water should be deionised water, distilled water or purified water.

How often should I change out the water?

Generally speaking, the water changing frequency is 3 months. It can also depend on the actual working environment of the recirculating water chillers. For example, if the working environment is too inferior, the changing frequency is suggested to be 1 month or shorter.

What is the ideal room temperature for the chiller?

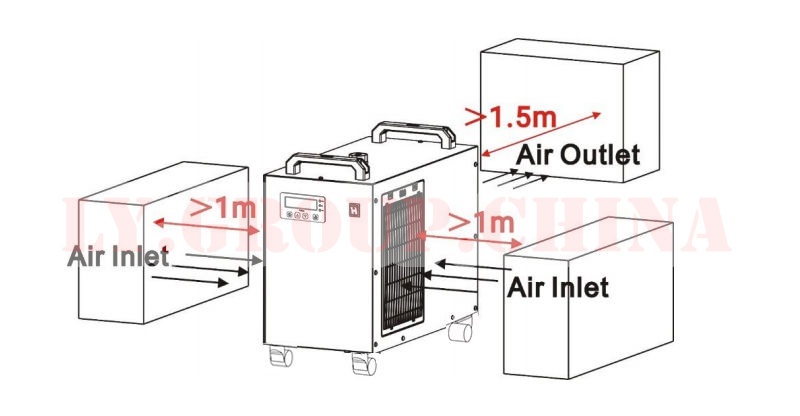

The working environment of the industrial water chiller should be well ventilated and the room temperature should not be higher than 45 degree C.

How to prevent my chiller from freezing?

For users living in high latitude areas especially in winter, they often face the frozen water problem. To prevent the chiller from freezing, they can add an optional heater or add anti-freezer in the chiller.

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!