Automatic Metal Precision Home Use Lathe LY EL300-750mm Simple CNC Programming Lathe Engraver Cutting Machine with Base Cutter

Product Detail

Product Tags

EL250/300 Automatic Metal Precision Home Lathe Customized Small Simple CNC Programming Lathe 1.5kw 2.2kw Motor Distance between two centers 550mm/750mm For Stainless Steel, Wood, Iron, Aluminum, Copper and other types of non-ferrous metals, as well as wood, nylon and so on.

EL250/300 High precision electronic metal lathe Customized Spindle bore diameter 26mm/38mm Spindle taper MT4/MT5 for small mechanical parts and crafts processing and manufacturing.

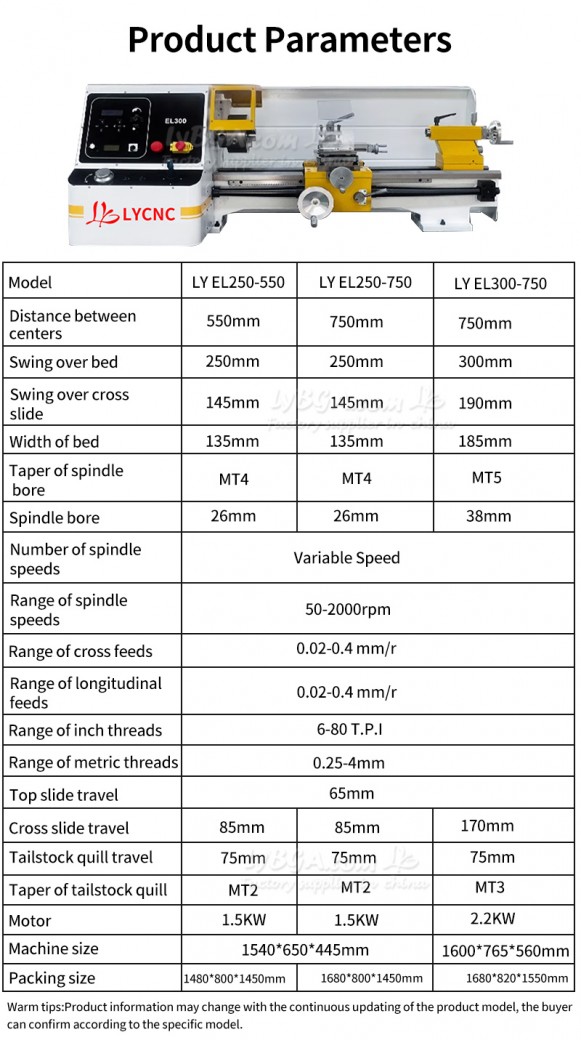

Parameters

|

Model |

EL250-550 |

EL250-750 |

EL300-750 |

|

Distance between centers |

550mm |

750mm |

750mm |

|

Swing over bed |

250mm |

300mm |

|

|

Swing over cross slide |

145mm |

190mm |

|

|

Width of bed |

135mm |

182mm |

|

|

Taper of spindle bore |

MT4 |

MT5 |

|

|

Spindle bore |

26mm |

38mm |

|

|

Number of spindle speeds |

Variable Speed |

||

|

Range of spindle speeds |

50-2000rpm |

50-2000rpm |

|

|

Range of cross feeds |

0.02-0.4 mm/r |

0.02-0.4 mm/r |

|

|

Range of longitudinal feeds |

0.02-0.4 mm/r |

0.02-0.4 mm/r |

|

|

Range of inch threads |

6-80 T.P.I |

6-80 T.P.I |

|

|

Range of metric threads |

0.25-4mm |

0.25-4mm |

|

|

Top slide travel |

65mm |

65mm |

|

|

Cross slide travel |

85mm |

170mm |

|

|

Tailstock quill travel |

75mm |

75mm |

|

|

Taper of tailstock quill |

MT2 |

MT3 |

|

|

Motor |

1.5KW |

2.2KW |

|

|

Machine size |

1540*650*445mm |

1600*765*560mm |

|

|

Packing size |

1480*800*1450mm |

1680*800*1450mm |

1680*820*1550mm |

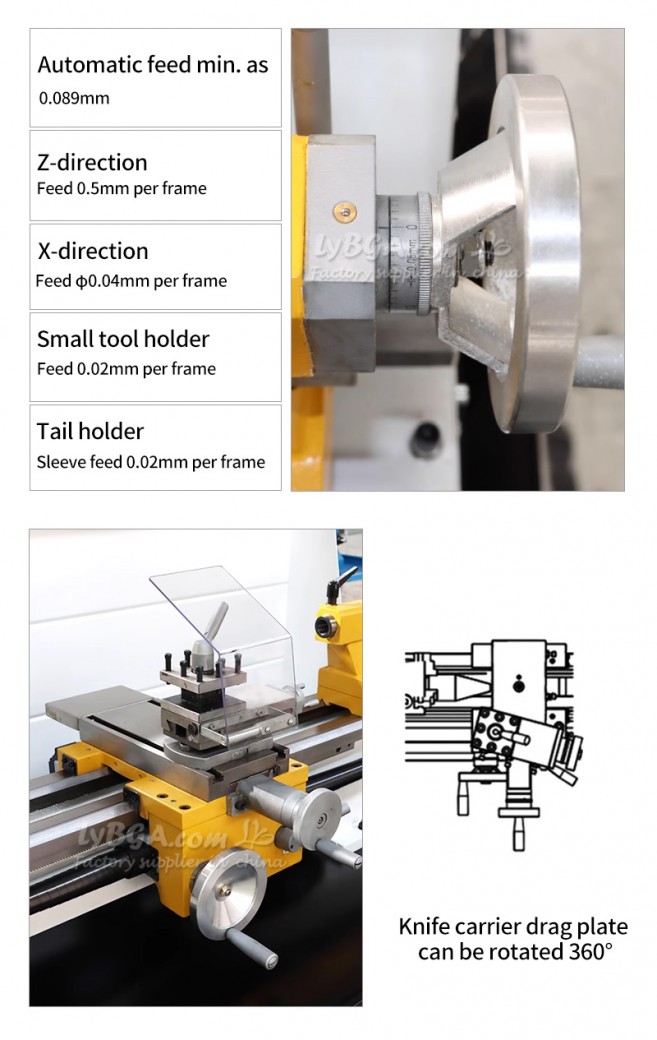

High-quality materials:

Carbon steel stamping tabletop, non-marking and odorless rubber pad, aluminum body, nylon wheels and handles, powder coating, high wear resistance

Flexibly moving:

360 rotating bearing top plate and double roller bearing design make it flexible and easy to move heavy objects.

Safe use:

Safe and stable non-slip supporting base, uniform bearing capacity, stable driving, labor-saving, wear-resistant and durable

Easy adjustment:

Manually rotate the knob to lower or raise the foot pad according to request, easy and convenient.

Features:

1. Great news for machine fans, more easy for operation, no need for highly skilled operators

2. Heavy duty stand with level adjustment and fix function, super convenient

3. Full automation, allowing for easier, quicker work

4. Highly versatile, allowing for use in the creation of all kinds of products and parts

5. Cost efficiency, offering a range of financial benefits, including: Low setup costs, Machining costs, Labor costs and less material waste

Automatic Metal Precision Home Lathe

Easy Programming/High Power 2.2KW/Simple Operation

Servo motor feed drive

X. Z-axis is driven by 1KW servo motor

Powerful inner core, powerful output

Quality Upgrade 6 Guarantees

Precision Quality

Long-lasting Durability

Tight Processing

Efficient Work

Thoughtful After-sales Service

Factory Direct Sale

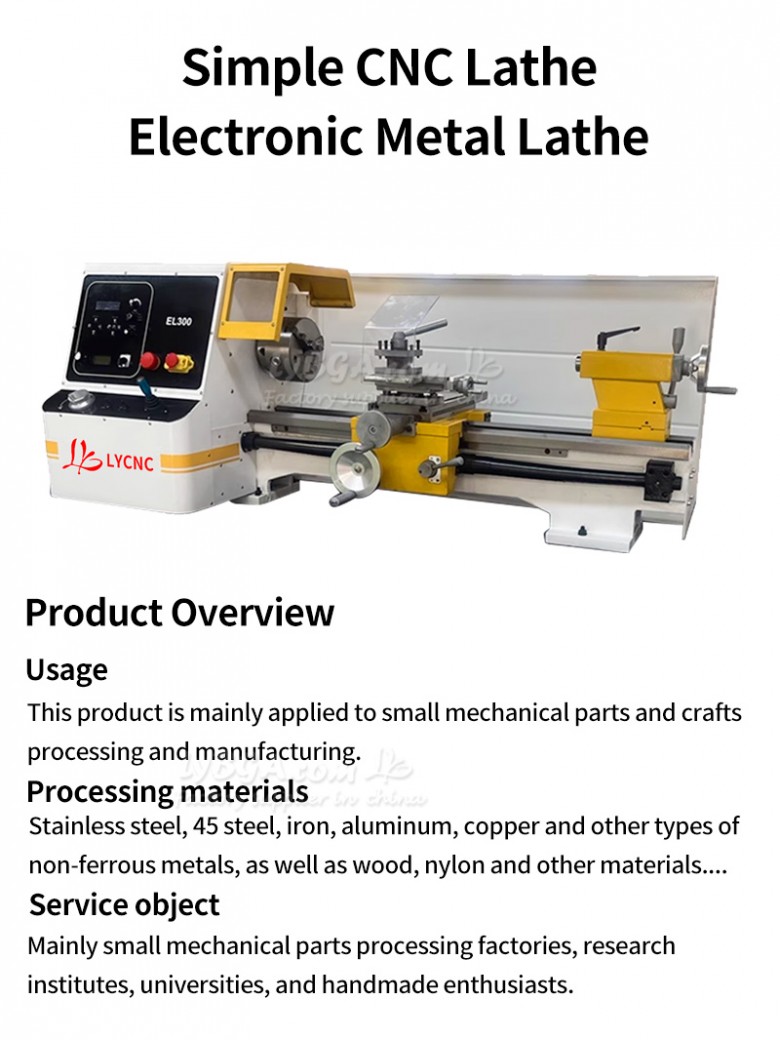

Simple CNC Lathe

Electronic Metal Lathe

Product Overview

Usage

This product is mainly applied to small mechanical parts and crafts processing and manufacturing.

Processing materials

stainless steel, 45 steel, iron, aluminum, copper and other types of non-ferrous metals, as well as wood, nylon and other materials….

Service object

Mainly small mechanical parts processing factories, research institutes, universities, and handicraft enthusiasts.

Lathe technology show

Pursuit of details / quality of large factories / easy to operate / professional manufacturing / strength certification

Precision craftsmanship

Craftsmanship for excellence

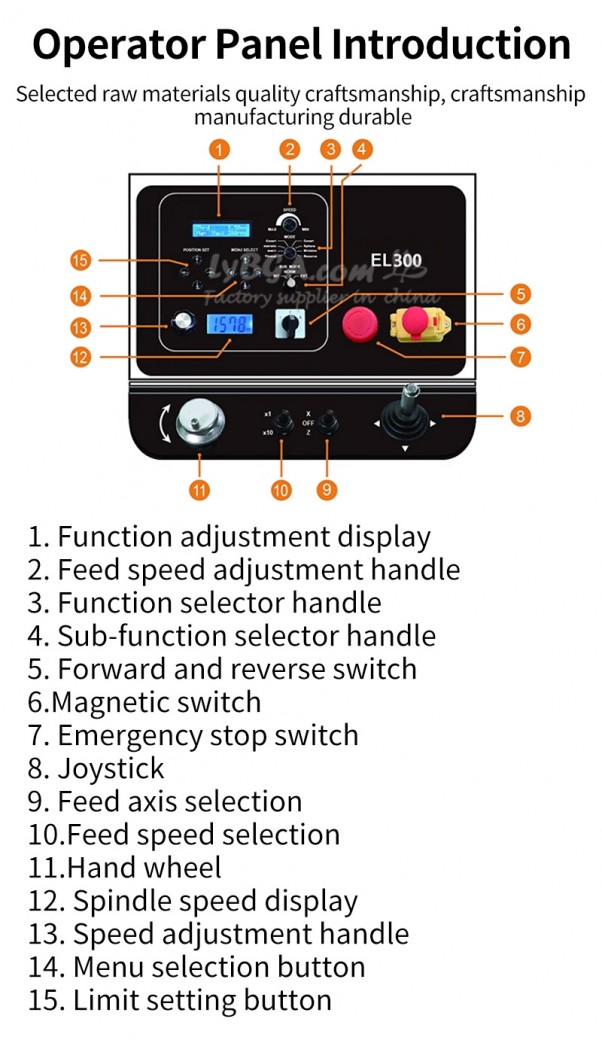

Operator Panel Introduction

Selected raw materials quality craftsmanship, craftsmanship manufacturing durable

1. Function adjustment display

2. Feed speed adjustment handle

3. Function selector handle

4. Sub-function selector handle

5. Forward and reverse switch

6. Magnetic switch

7. Emergency stop switch

8. Joystick

9. Feed axis selection

10. Feed speed selection

11. Hand wheel

12. Spindle speed display

13. Speed adjustment handle

14. Menu selection button

15. Limit setting button

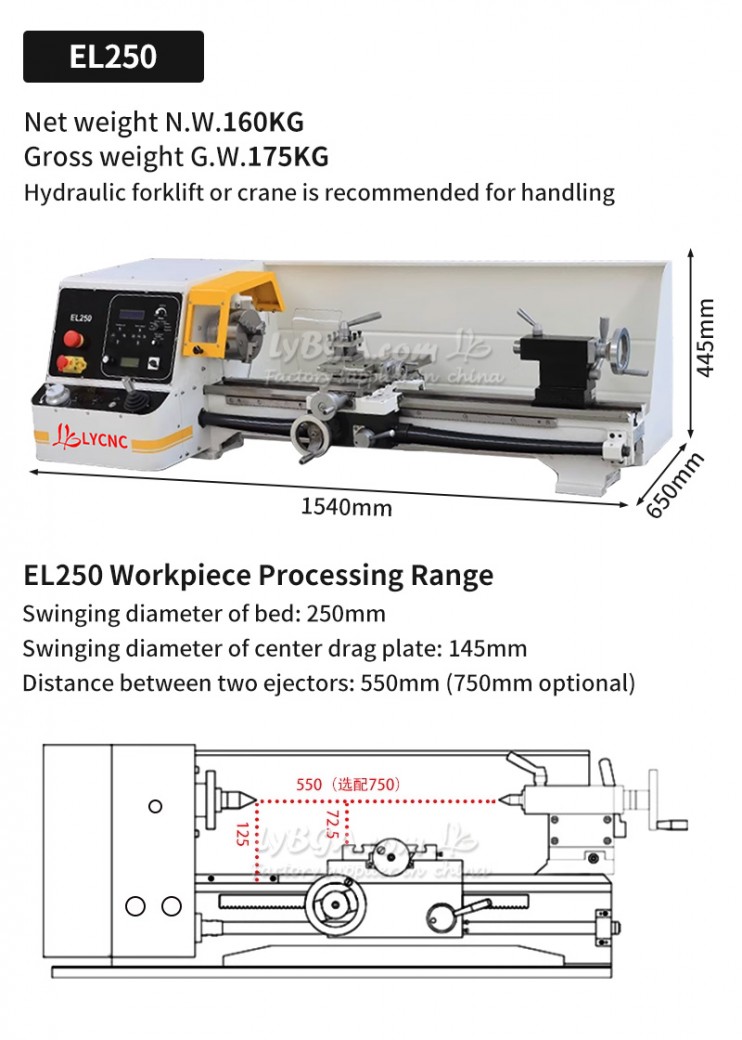

EL250

Net weight N.W.160KG

Gross weight G.W.175KG

Recommended to use hydraulic forklift or crane to carry

EL250 Workpiece Processing Range

Swinging diameter of bed: 250mm

Swinging diameter of center slide: 145mm

Distance between two ejectors: 550mm (750mm optional)

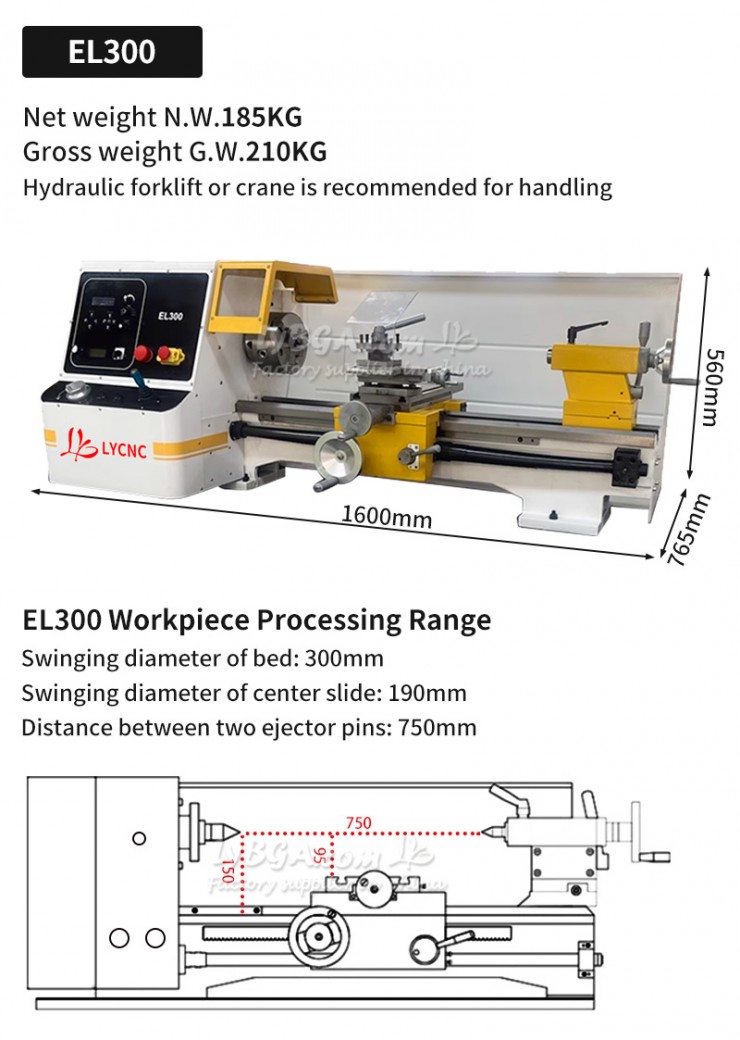

EL300

Net weight N.W.185KG

Gross weight G.W.210KG

Hydraulic forklift or crane is recommended.

EL300 Workpiece Processing Range

Swinging diameter of bed: 300mm

Swinging diameter of center slide: 190mm

Distance between two ejector pins: 750mm

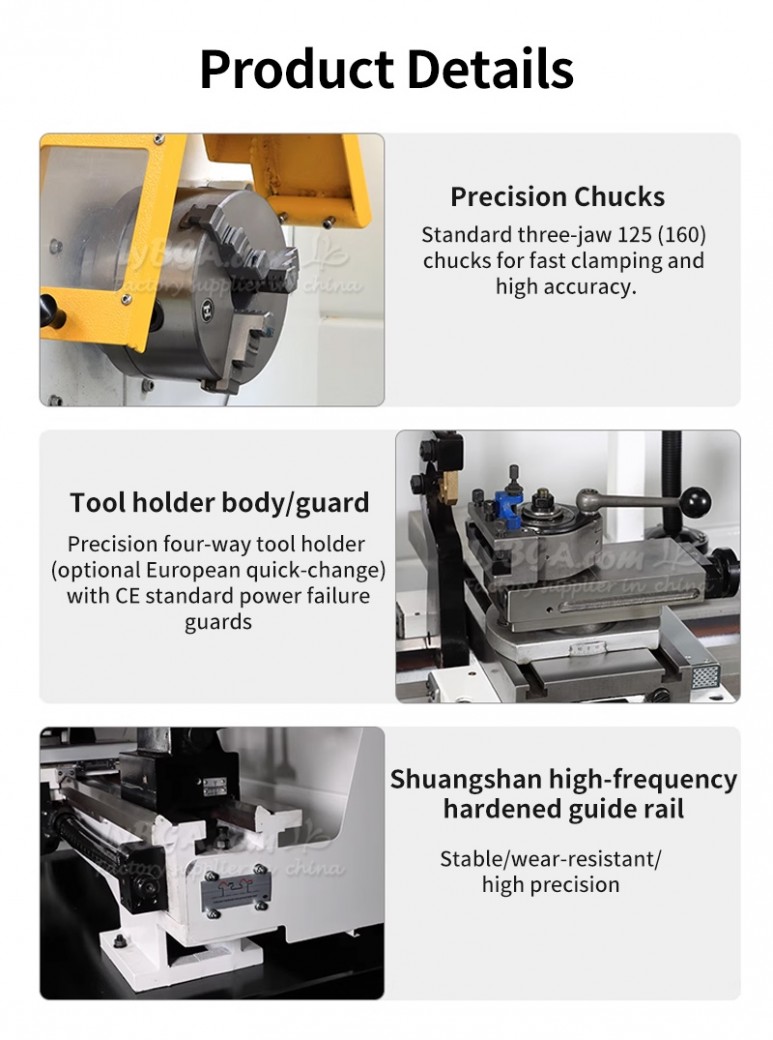

Product Details

Precision Chucks

Standard three-jaw 125 (160) chucks for fast clamping and high accuracy.

Tool holder body/guard

Precision four-way tool holder (optional European quick-change) with CE standard power failure guards

Shuangshan high-frequency hardened guide rail

Stable/wear-resistant/high precision

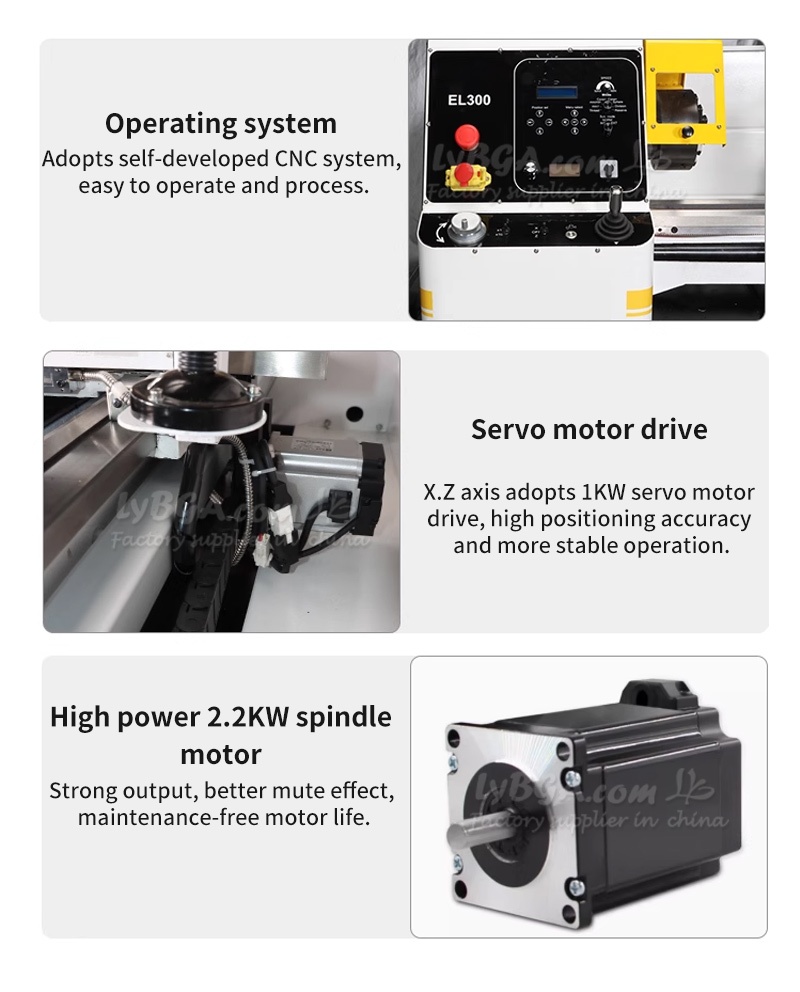

Operating system

adopts self-developed CNC system, easy to operate and process.

Servo motor drive

X.Z axis adopts 1KW servo motor drive, high positioning accuracy and more stable operation.

High power 2.2KW spindle motor

Strong output, better mute effect, maintenance-free motor life.

Thanks for your order!

Product Pictures

Questions, issues or concerns? I'd love to help you!