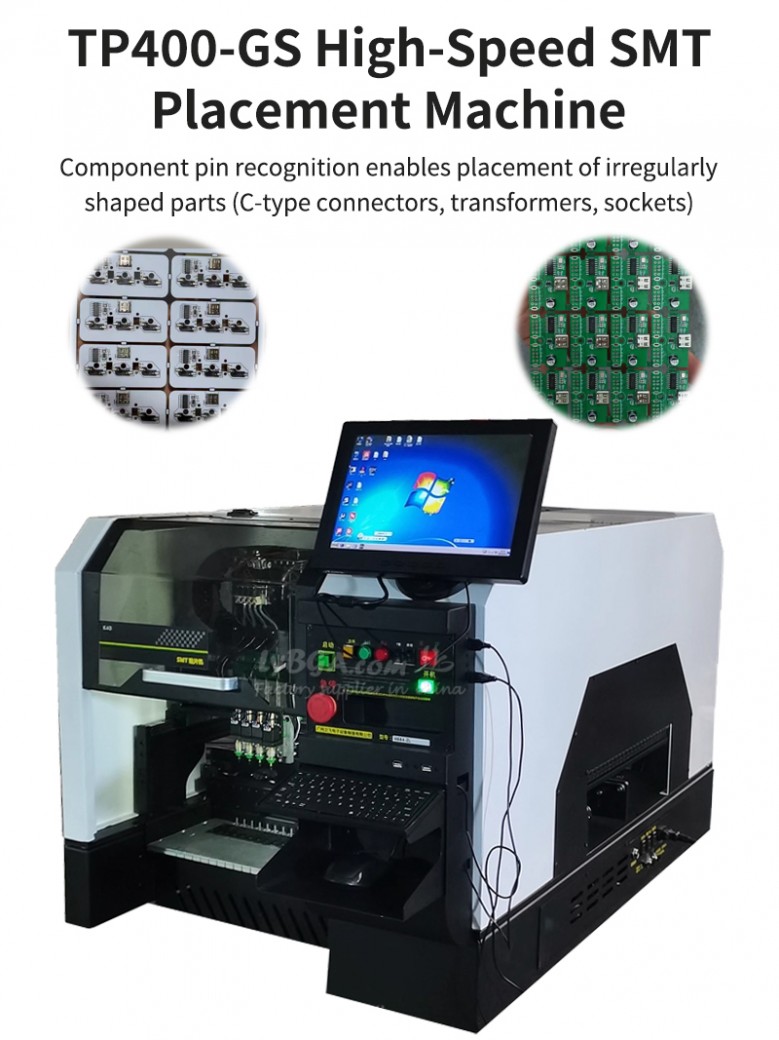

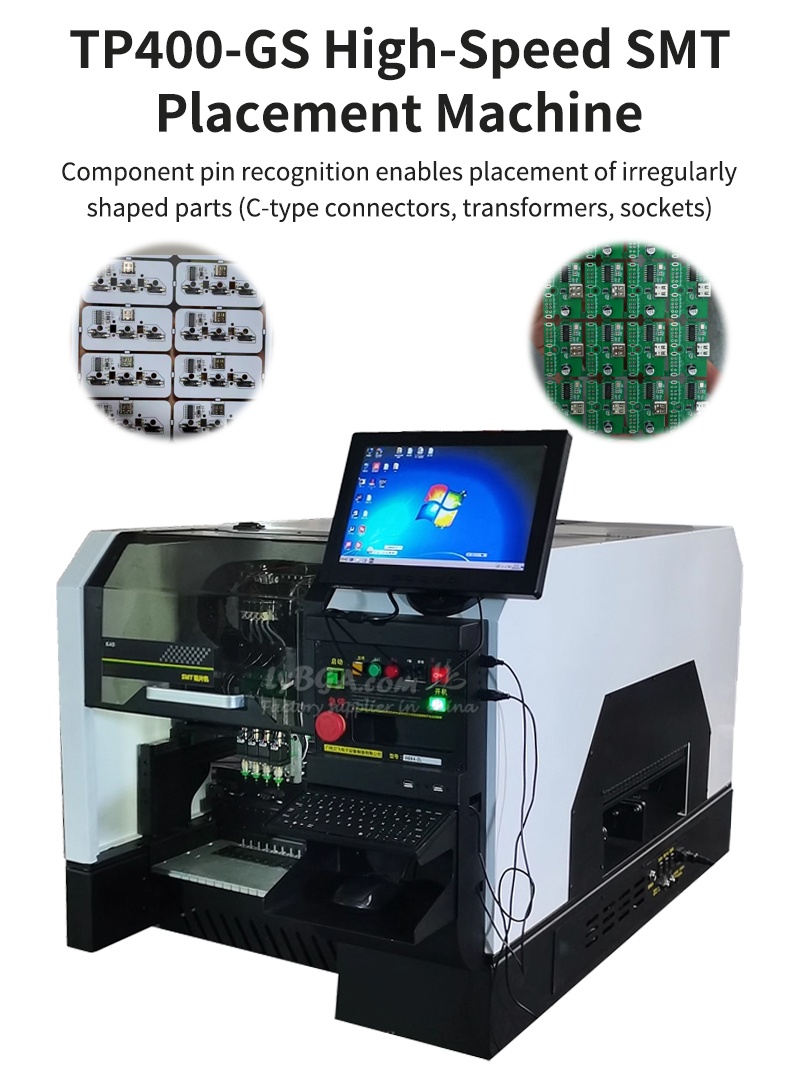

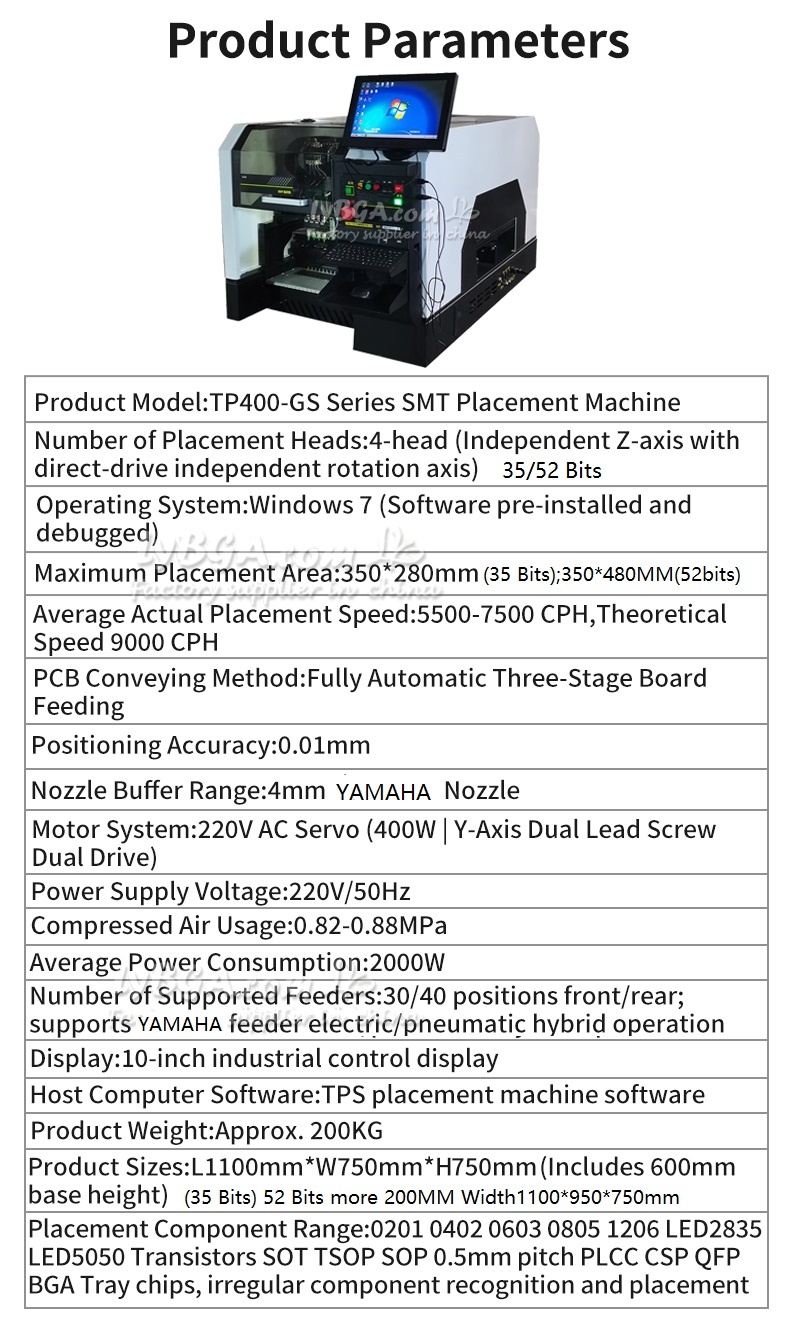

Industrial Double Vision-guided Pick and Place Machine TP400 4 Head 35/52 Bits 350x280mm/350x480mm High Speed SMT Chip Mounter

Product Detail

Product Tags

LY-TP400-GS Series Double Vision High Speed Flying Camera System pick-and-place machine 4-head 35/52-bits Maximum Placement Area 350*280mm/350*480mm Component Angle 0-360° Maximum Z-Axis Travel 32mm 2000W

LY TP400-GS High-speed SMT placement machine Desktop SMT Placement Machine Fully Automatic 3-Stage Automatic Board Feeding 220V

RE:

1 .Standard accessories Nozzle x 10

( 503 x 6 / 505 x 2 / 507 x 2 )

2.Feeder stock is YAHAMA brand (But no feeders with machine, customer need to buy themselves)

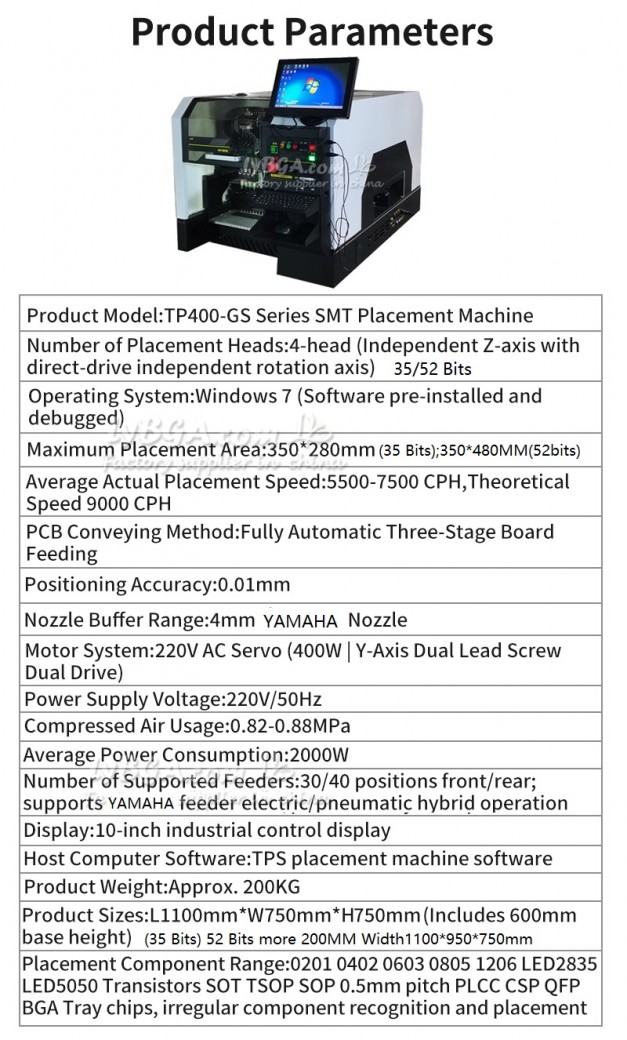

Product Specifications

|

Product Model |

TP400-GS Series |

|

Number of Placement Heads |

4-head (Independent Z-axis with direct-drive independent rotation axis) 35 Bits/52 Bits (Optional) |

|

Recognition Method |

High-speed non-stop aerial photography system |

|

Operating System |

Windows 7 (Software pre-installed and debugged) |

|

Camera |

Flight camera + MARK recognition camera (2 total) |

|

Upper Camera Brand |

Hikvision 6MP network rolling shutter camera |

|

Lower Camera Brand |

Hikvision 13MP USB 3.0 global shutter camera |

|

Maximum Placement Area |

350*280mm(35 Bits); 350*480mm(52 Bits) |

|

Maximum Z-Axis Travel Distance |

32mm Independent Z-Axis with Protective Nozzle, Closed-Loop Motor Capable of Handling 15mm Height Capacitors/Inductors |

|

Average Actual Placement Speed |

5500-7500 CPH | Theoretical Speed 9000 CPH |

|

PCB Conveying Method |

Fully Automatic Three-Stage Board Feeding |

|

Positioning Accuracy |

0.01mm |

|

Nozzle Buffer Range |

4mm YAMAHA Nozzle |

|

Motor System |

220V AC Servo (400W | Y-Axis Dual Lead Screw Dual Drive) |

|

Guide Rail Slider |

Domestic HGH20CA Series |

|

Lead Screw Brand |

Japanese Kuroda 1620 |

|

Power Supply Voltage |

220V/50Hz |

|

Compressed Air Usage |

0.82-0.88MPa |

|

Average Power Consumption |

2000W |

|

Number of Supported Feeders |

30/40 positions front/rear; supports YAMAHA feeder electric/pneumatic hybrid operation |

|

Placement Component Range |

0201 0402 0603 0805 1206 LED2835 LED5050 Transistors SOT TSOP SOP 0.5mm pitch PLCC CSP QFP BGA Tray chips, irregular component recognition and placement |

|

20 Bulk Tray Assemblies (Automatic recognition and pickup) |

|

|

Automatic feeder position correction (vision scanning correction) |

|

|

Post-placement compensation (components with ejection failures or shortages are replenished later without manual intervention) |

|

|

Component Angle |

0-360° |

|

Display |

10-inch industrial control display |

|

Host Computer Software |

TPS placement machine software |

|

Product Weight |

Approx. 200KG |

|

Product Dimensions |

L1100mm*W750mm*H750mm 35 Bits; L1100mm*W950mm*H750mm 52Bits |

Features

1. Automatic track width adjustment (auto-reset, automatically adjusts track width for different PCBs)

2. Component pin recognition, capable of placing irregular components (C-type connectors, transformers, sockets)

Proprietary control system (dual network card communication, ultra-high stability, 75,000 lines of robust code—pin recognition alone, irregular component angle processing, and XY offset handling comprise 15,000 lines)

No threshold or brightness adjustment required. For different component packages, simply capture one image of a representative component. Switching between PCBs requires no repeated imaging—one image per package type suffices.

Supports high-precision camera nine-point calibration mode (factory-calibrated out-of-the-box, no re-calibration needed. Customer self-calibration requires manufacturer authorization and software permissions).

Vertical Placement Machine

We also offer vertical placement machines. For more information on this product, please contact our sales team.

1. Compatible with vibratory feeders for inserting various terminals, transformers, LED lamps, etc

2. Compatible with YAMAHA irregular feeders for inserting tape-and-reel resistors and capacitors

3. Supports irregular label placement

Thanks for your order!

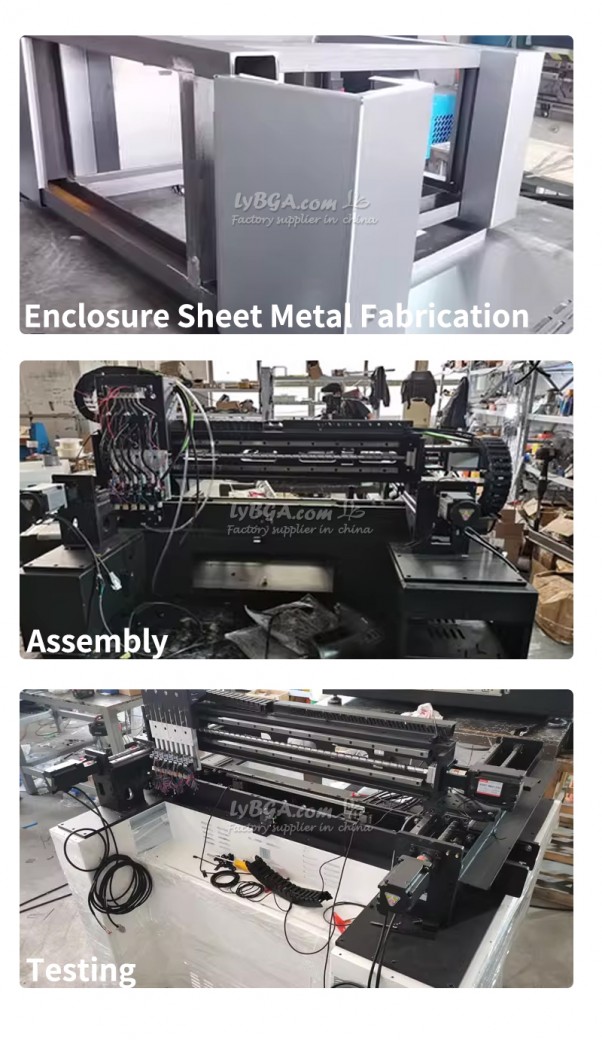

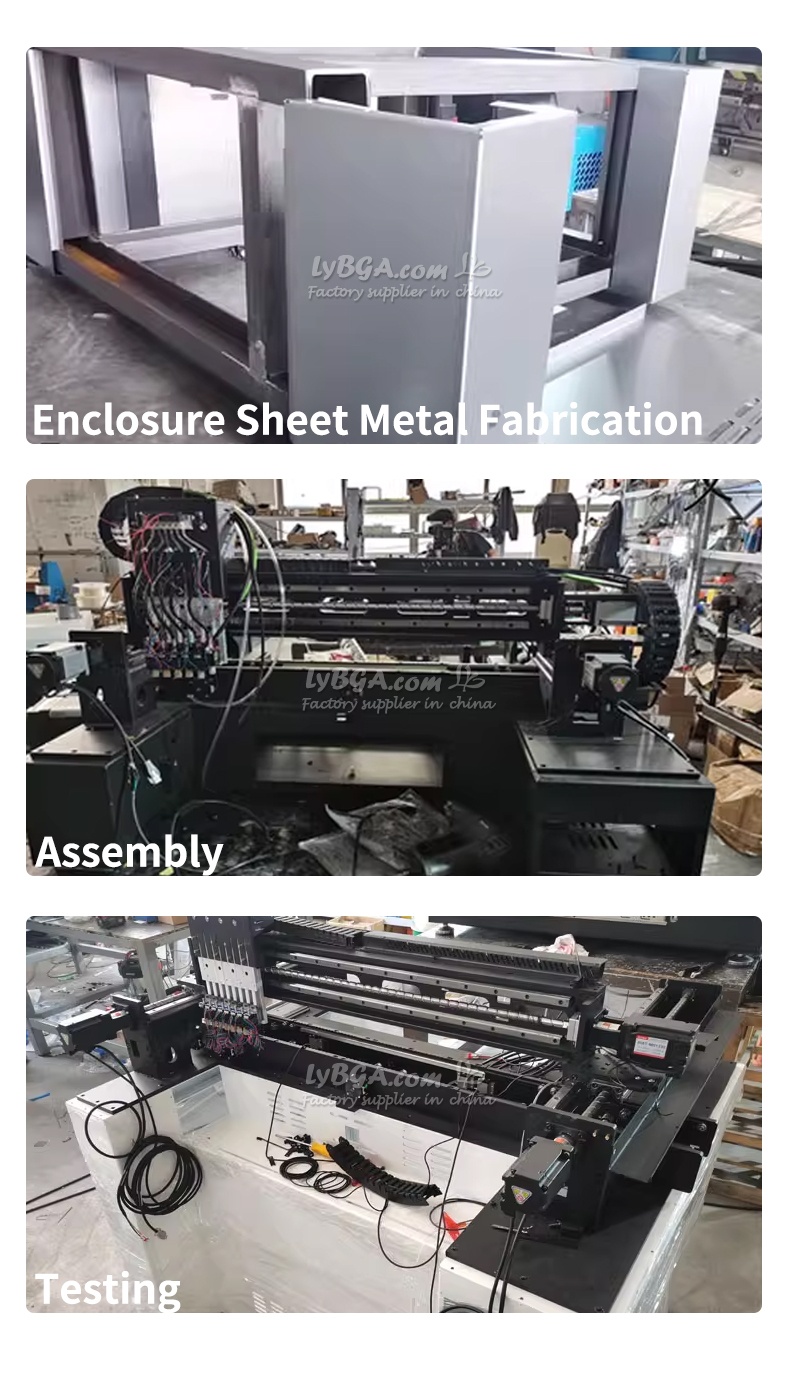

Product Pictures

Questions, issues or concerns? I'd love to help you!